Follow these guidelines when working with TruPlan.

- After importing a source file into

TruPlan, check that the layup (or draping) direction is correct. (Sometimes it can get reversed on import.) If it is not, double-click the appropriate layup in the

TruPlan browser and click

Layup Direction

to reverse it.

to reverse it.

- When creating flats in a source file (with a third-party program), follow these guidelines so that they display properly in

TruPlan:

- They must of type "material roll" rather than "unfold assembly."

- They must be on a plane parallel to the global XY plane.

- Their 0-degree direction must be parallel to the global X-axis.

- In your host application, create a template file that contains all the materials and packaging you use. (For example, in Autodesk Inventor, .) Use this template whenever you create a part for TruPlan. This way while working with the part in TruPlan, you will have access to all your materials without needing to recreate them.

- If you are using rosettes in your source CAD software, make sure you define their axis systems under the axis systems node of the project. Otherwise, the rosettes will not be included in the XML file and cannot be imported into TruPlan.

- When creating STL files to be imported into TruPlan, include the unit type in the file name for easy reference; for example, my_file_inches.STL. You need to know the unit type during import and TruPlan does not detect it for you.

- Make sure there are no duplicate layup, sequence, or ply names in a single part. TruPlan does not warn for duplicate names.

- Part names (root node of the TruPlan browser) and layup, sequence, and ply names must not contain characters that are not allowed in file names, such as: / \ : * ? " < > & ~ ' ^ ; ,

- Tabs are also not permitted in file names. These rules are not enforced by TruPlan. Failure to follow them will produce errors, missing parts, or bad parts.

- Do not include portions of the part name in lower level entities. This makes ply labels very long.

- Avoid inclusion of prefix or postfix in part name, in the top node of the TruPlan browser (example: MED_prefix). This is to avoid long ply labels.

- Avoid inclusion of prefix or postfix in sequence and ply name. This is also to avoid long ply labels.

- Use a material ID for the packaging name instead of the material name. Manufacturing material IDs are not standardized among suppliers. This makes it harder to move manufacturing of a given part from one location to another.

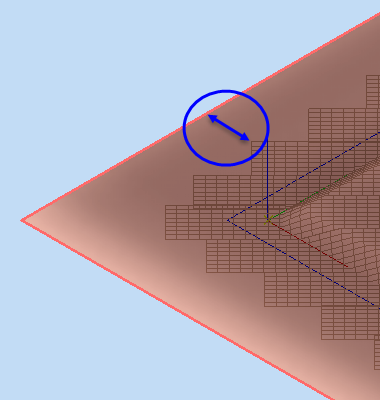

- The workpiece surface needs to be larger than the ply boundaries of the largest ply in order to calculate tool paths correctly. The surface must extend by at least one bandwidth past the ply boundary. For example, if you have a fiber placement machine that uses a 150mm band, then you will need to extend the reference surface at least 150mm past every edge of the largest ply.