Primary Tool Axis Mode

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

The options in the Tool Axis Mode list let you specify the main behavior of the tool axis for multi-axis machining.

Vertical: The tool axis aligns itself with the specified tool orientation.

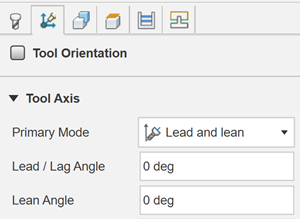

Lead and Lean: Tilts the tool axis by specifying lead and lean angles. A Lead angle tilts the tool in the direction of travel. A Lean angle tilts the tool sideways in relation to the direction of travel. A Lead and Lean angle of 0 aligns the tool axis so that it is always perpendicular to the underlying surface geometry. As the surface you are machining changes, so does the tool axis, to ensure it continues to machine perpendicular to the part. Selecting this option lets you specify settings to increase machining efficiency.

Note: Lead and Lean is currently available only for the Steep and Shallow strategy.From Point: The tip of the tool always turns away from a point.

To Point: The tip of the tool always turns toward a point.

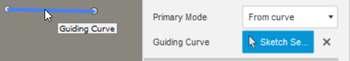

From Curve: The tip of the tool always turns away from a curve/line.

To Curve: The tip of the tool always turns toward a curve/line.

Lead and Lean

You can specify two different angles - Lead and Lean. The Lead Angle is applied in the tool's direction of travel, and then the Lean Angle is applied perpendicular to the direction of travel.

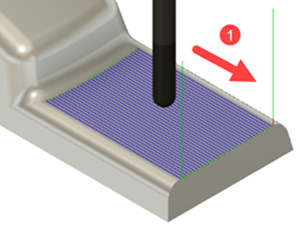

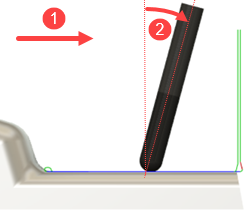

- Lead / Lag Angle: Tilts the tool axis forwards or backward with reference to the direction of travel. You can use a Lead / Lag Angle to avoid machining with the center of a ball-nosed tool. A Lead Angle of 15° is typically used to ensure you machine with the actual flutes of a ball-nosed tool. Tilting the tool in the direction of travel is often referred to as Lead. Tilting the tool opposite the direction of travel is often referred to as Lag.

|

| 1 - Direction of travel |

|

|

| 1 - Direction of travel | 1 - Direction of travel |

| Lead / Lag Angle = 15 degrees | Lead / Lag Angle = -15 degrees |

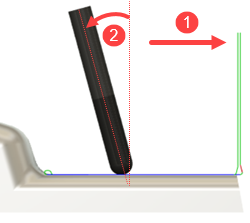

- Lean Angle: Tilts the tool sideways with reference to the direction of travel.

|

|

| 1 - Direction of travel | Side view |

| 2 - Direction of sideways tilt | Lean Angle = 30 degrees |

When machining a convex surface on a steep wall, you can specify a nonzero Lean Angle to tilt the tool closer to the part so you can machine with more of the tool's flute length. Using more of the tool's flute length lets you machine using larger stepdown values, which reduces machining time.

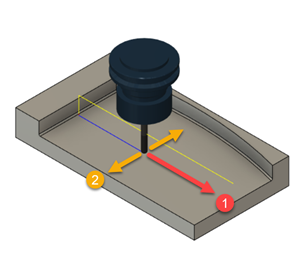

|

|

| Lead Angle = 0, Lean Angle = 0 | Lead Angle = 0, Lean Angle = - 88 |

| Stepdown = 0.5 mm | Stepdown = 1 mm |

From Point, To Point, From Curve and To Curve

Use the From Point, To Point, From Curve, and To Curve settings to give you more control to machine areas that are difficult to access with a tool. You can use existing geometry on a model or sketch a point, line, or curve to guide the tool axis to turn toward or away from during machining.

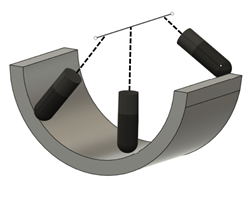

|

|

| From Point | To Point |

|

|

| From Curve | To Curve |

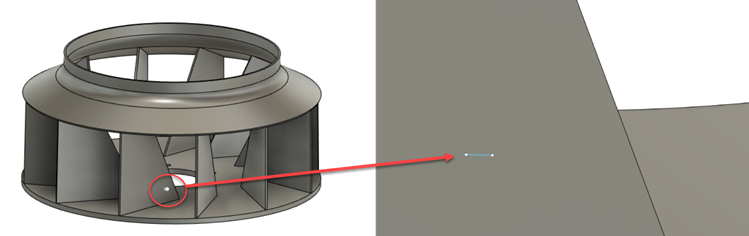

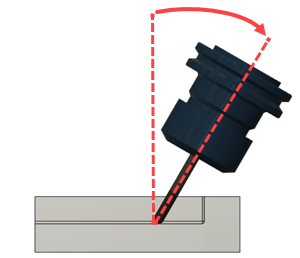

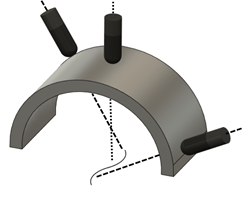

In the example below, the tool cuts a blade of a blower that would otherwise be difficult to machine without tilting the tool axis.

The toolpath that gives the tool access to the full blade is programmed using a From Curve option from the Primary Mode list by using a line that is sketched in the Design workspace and selected as the Guiding Curve.