Turning Thread strategy

The Turning Thread strategy creates cylindrical and conical threads on a turned part.

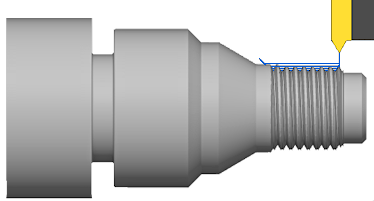

Turning Thread on the outside diameter of the part.

Modes

Turning Mode determines which side of the geometry to machine the threads:

- Outside Threading: Creates threads on the outside of the selected geometry.

- Inside Threading: Creates threads on the inside of the selected geometry.

Definition Method

Definition Method determines how the thread geometry and parameters are defined:

- Manual: Lets you enter values to manually define the thread geometry.

- Standard: Lets you select Fusion-generated threads and detects values to define the thread geometry automatically.

Geometry

Select one or more faces where to create a thread. To contain the toolpath within specific boundaries, specify the Confinement parameters.

Thread

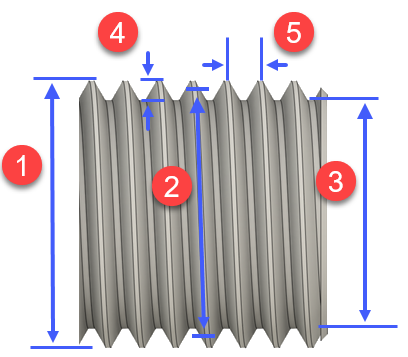

You can machine a right-handed or left-handed thread. A threading tool removes stock to create a thread with the required pitch, diameter, and depth.

Right handed thread; major diameter (1), pitch diameter (2), minor diameter (3), thread depth(4), thread pitch (5).

First pass

When programming a turning thread operation, the first cut can often occur at a large depth which can cause excessive vibrations and tool wear. While this may not occur when cutting softer materials, but for harder materials, it is important to determine the depth of the first cut for improved cutting conditions.

Canned cycle

To output the threading motion as a canned cycle, select the Use Cycle checkbox on the Passes tab. Though, it may limit some of the available features. A canned cycle is a sequence of operations programmed using a G-Code that a turning machine can perform. It simplifies toolpath programming.

For more information, watch the Turning thread video.