During the manufacture of sheet metal parts, it is often critical that the physical bends be created in a particular sequence. This bend order sequence can be defined while the model is displayed in the flat pattern state. Once defined, the bend sequence can be extracted to bend table annotation on production drawings.

Autodesk Inventor supports bend order annotation on bend centerlines created when formed features are flattened as well as on cosmetic bend centerlines that have been added manually.

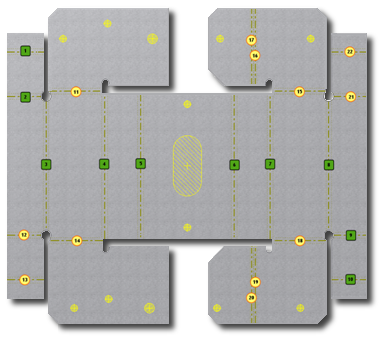

Bend order is indicated on the flattened state of the model with colored glyphs containing a sequence number. Circular glyphs of one color indicate bends that retain the default sequence. Square glyphs of another color indicate bends that were edited. The active color scheme determines the colors used.

Bends can be resequenced in three ways:

|

Directed Reorder - Prompts for the selection of a start glyph and an end glyph. Using an algorithm that traverses the flat face, bend centerlines that lie between the selected start and end glyphs are renumbered. |

|

|

Sequential Reorder - After selecting an initial bend centerline glyph to change, sequential selections are manually made until the new sequence is complete. |

|

|

Individual Edit - A specific bend centerline glyph is selected and changed. |

Multiple bend centerlines can be tagged with duplicate sequence identifiers.