In this tutorial, you set up and run a cooling analysis on a 2-cavity tool on the panel. The cooling analysis calculates a steady state, or average temperatures over the entire mold cycle. At a minimum, all that is modeled is the part, mold boundary, and cooling channels. With this method, it is easy to modify the location of the cooling channels to see the influence of the cooling channel location. This tutorial uses the model of the parts, feed system, and mold boundary done in the packing analysis tutorial. You do not have to complete the packing analysis tutorial to complete this one, but review the steps. If you would like to review the previous tutorials click here.

In this tutorial, you will do the following:-

Create a project

-

Import a study

-

Create the cooling lines

-

Input the process settings and run the analysis

-

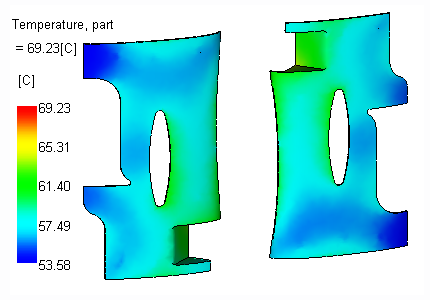

Review results

Before you begin, click here to download the model files for all the quick start tutorials.

When ready click here to start the tutorial.