|

Access: |

Ribbon:

CAM tab

Job panel

Job panel

Setup

Setup

|

Common setup parameters for model orientation and origin, stock selection, stock specifications, and post processing are configured on the Setup operation dialog.

Model tab settings

Model tab settings

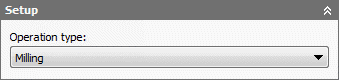

Setup

The machining setup can be described specifying the machining method. This parameter is made available to the post processor.

Operation type:

Specifies the machining method.

Milling

Milling - Use Milling when processing toolpaths for a mill regardless of configuration.

Turning

Turning or mill/turn - Use Turning when processing toolpaths for a lathe, including lathes with live tooling and mill/turn configurations.

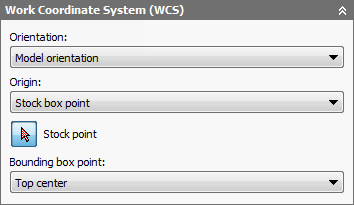

Work Coordinate System (WCS)

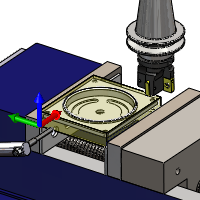

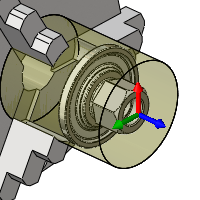

The Work Coordinate System (WCS) specifies the global coordinate system in which the post processed toolpath is output. The WCS defaults to the model orientation.

When editing and simulating, the coordinates are also presented in the WCS by default.

Orientation:

The Orientation: drop-down menu provides the following options to define the setup orientation of the X, Y, and Z WCS axes:

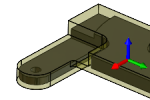

- Model orientation - Uses the orientation of the current part for the WCS orientation.

- Select Z axis/plane & X axis - Select a face or an edge to define the Z axis and another face or edge to define the X axis. Both the Z and X axes can be flipped 180 degrees.

- Select Z axis/plane & Y axis - Select a face or an edge to define the Z axis and another face or edge to define the Y axis. Both the Z and Y axes can be flipped 180 degrees.

- Select X & Y axes - Select a face or an edge to define the X axis and another face or edge to define the Y axis. Both the X and Y axes can be flipped 180 degrees.

- Select coordinate system - Sets the WCS orientation for the setup from an Inventor User Coordinate System (UCS) in the model. This uses both the origin and orientation of the existing coordinate system. Use this option if your model does not contain a suitable point and plane for your operation.

Origin:

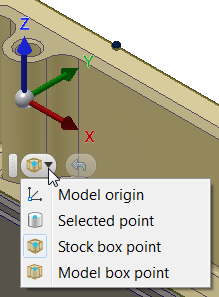

The Origin: drop-down menu offers the following options for locating the WCS origin:

- Model origin - Uses the coordinate system (WCS) origin of the current part for the WCS origin.

- Selected point - Select a vertex or an edge for the WCS origin.

- Stock box point - Select a point on the stock bounding box for the WCS origin.

- Model box point - Select a point on the model bounding box for the WCS origin.

The Origin mini-toolbar displays automatically when Setup is invoked and offers an alternative to the dialog box for WCS origin selection.

The Origin mini-toolbar drop-down menu. Click the Undo button to the right of the drop-down to reselect the WCS origin.

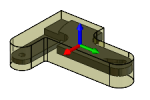

Orientation & Origin

Coordinate System

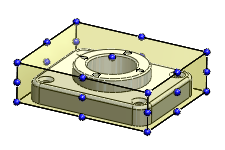

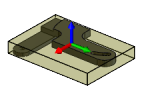

Bounding box point:

When either the Stock box point or Model box point origin options are selected, you can then use the Bounding box point: drop-down menu to specify a point on the bounding box to locate the WCS origin.

Bounding box points

Model

The model specified for the setup is used by default for all 3D surface machining operations. The selected model is also used during the simulation of a toolpath.

Fixture

Select any fixtures that should be included for collision detection when verifying toolpaths during stock simulation.

Stock tab settings

Stock tab settings

The specified stock and fixture are used when simulating the generated toolpath, and can also be used by some machining strategies.

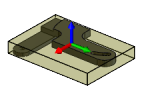

Cubic stock options

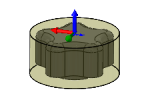

Cylindrical stock options

Mode:

Fixed Size Box and Relative Size Box

Fixed size box - Creates a cubic stock body that is of a specified (fixed) size. This is the default setting.

Relative size box - Creates a cubic stock body that is larger than the model by given offset values, rounded up to the nearest specified increment.

Dimensions - Displays the Width (X), Depth (Y), and Height (Z) dimensions of box setup stock.

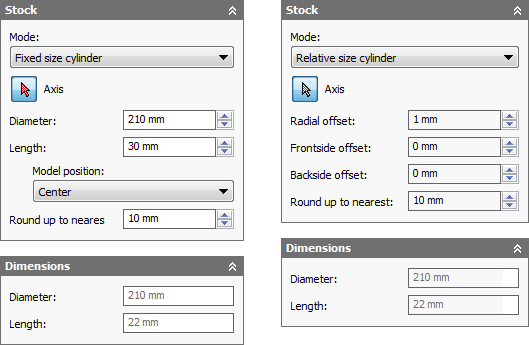

Fixed Size Cylinder and Relative Size Cylinder

Fixed size cylinder - Creates a cylindrical stock body that is of a specified (fixed) size. This is the default setting.

Relative size cylinder - Creates a cylindrical stock body that is larger than the model by given offset values, rounded up to the nearest specified increment.

Dimensions - Displays the diameter and length of cylindrical setup stock.

From Solid

From Solid - Gives complete control over stock definition by using a solid body in a multi-body part, or from a part file in an assembly.

Dimensions - Displays the Width (X), Depth (Y), and Height (Z) dimensions of the stock.

Mode:

Automatic

Automatic - Creates a cubic stock body that is larger than the model by given offset values.

From Extruded Sketch

From Extruded Sketch - Creates a stock body from a sketch

Stock reverse

Specifies which direction of the extrusion from sketch to be reversed.

Fixed Size Box Mode

- Width (X): - Enter a value to specify the stock width.

- Model position: Offset from left side (-X) - Specifies the offset of the stock in the negative X direction.

- Model position: Center - The model is centered along the X axis within the stock.

- Model position: Offset from right side (+X) - Specifies the offset of the stock in the positive X direction.

- Depth (Y): - Enter a value to specify the stock depth.

- Model position: Offset from back side (+Y) - Specifies the offset of the stock in the positive Y direction.

- Model position: Center - The model is centered along the Y axis within the stock.

- Model position: Offset from front side (-Y) - Specifies the offset of the stock in the negative Y direction.

- Height (Z): - Enter a value to specify the stock height.

- Model position: Offset from top (+Z) - Specifies the offset of the stock in the positive Z direction.

- Model position: Center - The model is centered along the Z axis within the stock.

- Model position: Offset from bottom (-Z) - Specifies the offset of the stock in the negative Z direction.

- Round up to nearest: - Specifies the rounding increment for the stock size.

Relative Size Box Mode

Selecting the Relative size box mode provides options to add stock to the top, bottom, and/or sides of the stock.

No additional stock

No additional stock - No offset values are added to the stock size.

Add stock to sides and top-bottom

- Side offset: - Specifies the additional stock on the sides.

- Top offset: - Specifies the additional stock on the top.

- Bottom offset: - Specifies the additional stock on the bottom.

Add stock to all sides

- Stock -X offset: - Specifies the offset of the stock in the negative X direction.

- Stock +X offset:: - Specifies the offset of the stock in the positive X direction.

- Stock -Y offset: - Specifies the offset of the stock in the negative Y direction.

- Stock +Y offset: - Specifies the offset of the stock in the positive Y direction.

- Stock -Z offset: - Specifies the offset of the stock in the negative Z direction.

- Stock +Z offset: - Specifies the offset of the stock in the positive Z direction.

- Round up to nearest: - Specifies the rounding increment for the stock size.

Fixed Size Cylinder Mode

- Axis - Specifies the axis of the cylindrical stock. Permissible selections include arcs, edges, and faces.

- Diameter: - Specifies the diameter of the stock.

- Length: - Specifies the length of the stock.

- Offset from front: - Positions the stock such that it is flush with the front face of the model.

- Center - Centers the model within the cylindrical stock.

- Offset from back - Positions the stock such that it is flush with the back face of the model.

- Round up to nearest: - Specifies the rounding increment for the stock size.

Relative Size Cylinder Mode

Like the Fixed size cylinder mode, the Relative size cylinder mode also lets you specify the axis of the cylindrical stock. In addition, you can specify radial, frontside, and backside offset values to better position your model relative to the stock.

- Axis - Specifies the axis of the cylindrical stock. Permissible selections include arcs, edges, and faces.

- Radial offset: - Specifies the radial offset of the stock.

- Frontside offset: - Specifies the distance to machine beyond the frontside of the model.

- Backside offset: - Specifies the distance to machine beyond the backside of the model.

- Round up to nearest: - Specifies the rounding increment for the stock size.

Stock offset:

Specifies the distance to offset the stock contour outwards.

Stock offset

Height:

Specifies the overall height of the stock.

Height

Post Process tab settings

Post Process tab settings

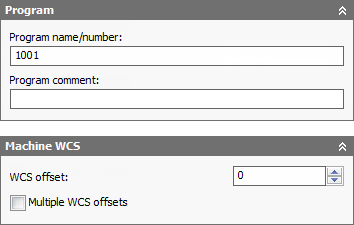

Post processing parameters like the program name or number, program comment, and work offset can be provided on the Post Process tab

The work offset is mapped by the post processor configuration to the corresponding zero table index (e.g. G54-G59) on the CNC control. A value of 1 would normally be setup to be the first available zero index on the CNC control (e.g. G54). The WCS and work offset are generally setup to match one another on a one-to-one basis.

Program name/number

Specifies the program name or number. This parameter is made available to the post processor.

Program comment

Specifies the program comment. This parameter is made available to the post processor.

WCS offset:

Identifies the desired workpiece coordinate system (WCS) for the setup. It is the responsibility of the post processor configuration to map this number to the actual WCS on the machine.

Multiple WCS offsets

Enable this check box to specify that the workpiece is to be duplicated.

WCS offset duplicates:

Specifies the number of workpiece duplicates. This is the total number of instances.

WCS offset increment:

Specifies the work offset increment used for workpiece duplication.

Operation order:

Specifies the ordering of the individual operations.

- Preserve order - Specifies that features are machined in the order in which they were selected.

- Order by operation - Specifies the ordering of the individual operations.

- Order by tool - Specifies the ordering of operations by tool. For example, all operations that use a Ø3/4" flat mill are machined first. Then the next set of operations that use another identical tool, a Ø1/4" flat mill for example, are machined next.

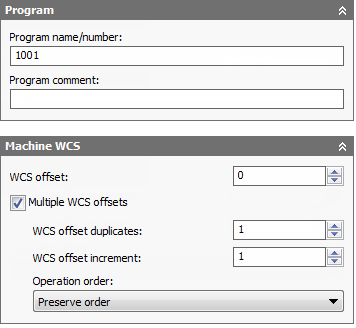

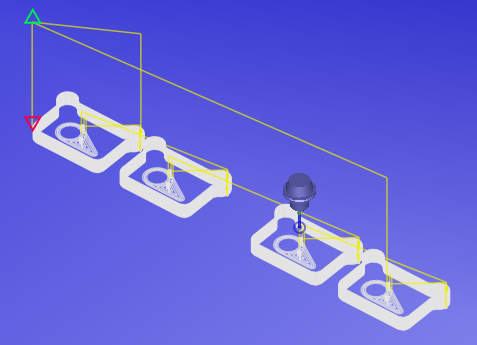

Using Multiple Setup Work Offsets

Inventor HSM Pro supports patterning of entire setups using the Multiple WCS offsets feature, which essentially duplicates entire setups using different work offsets. This feature is generally used when the individual position of each instance is not precisely known.

Once you enable Multiple WCS offsets, you can specify the total number of instances and the work offset increment to be used. You can also choose the order of the duplicated toolpath (by setup, by operation, or by tool).

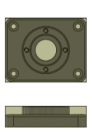

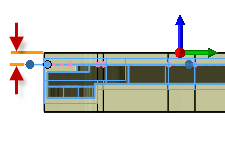

Enabling multiple work offsets

The setting for the WCS offset field depends on the post processor. In this case we are using a Fanuc post, so specifying 1 will use the first work offset (G54), the next field is the number of duplications, in this case 4, and the last is the increment, in this case 1, i.e. the next offsets will be G55, G56 and G57.

If the physical setups of each instance are evenly spaced, it is sometimes possible to use a normal pattern feature instead. This allows you to fully simulate the duplicated toolpath. However, this approach requires you to add toolpaths to align the stock for each instance.

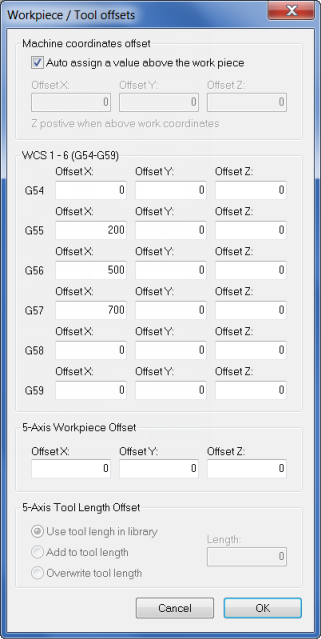

Using Backplot to Set Workpiece/Tool Offsets

The Multiple WCS offsets feature only applies to the post processing and setup sheet features. It is not possible to simulate the duplicated toolpath as the relative positions of each instance are not known inside Inventor HSM Pro (e.g. G54 in relation to G55). So to see the multiple work offsets we must look at the posted file in Inventor HSM Edit.

Within the editor, we set the work offsets by first clicking Backplot tab File panel

File panel

Backplot Window

Backplot Window

on the ribbon, and then clicking

Backplot tab

on the ribbon, and then clicking

Backplot tab

Other panel

Other panel

Set Workpiece/Tool Offsets

Set Workpiece/Tool Offsets

to display the Workpiece/Tool offsets dialog box.

to display the Workpiece/Tool offsets dialog box.

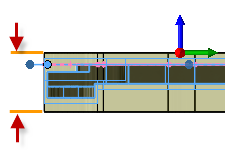

Setting work offsets in Inventor HSM Edit

Multiple work offsets in the posted file