Temperature control using heating fluids and coolants, alternatively in the same cooling circuits, is a common approach for rapid mold heating and cooling. Common heating fluids include saturated steam, superheated water or oil. Cold water is typically used as the coolant.

For the purposes of this simulation, the experiment can be set up in two ways. Select the one which represents your system most realistically.

- Time controlled

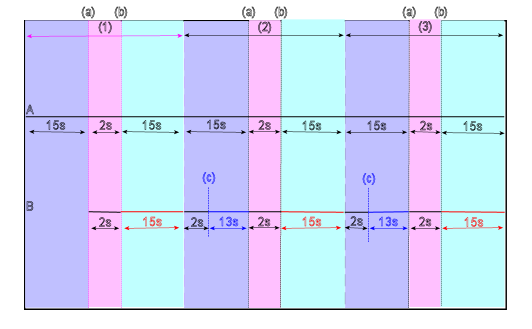

- In this mode, the mold is heated and cooled for a specific length of time. You can select whether to heat the mold when it is open, or closed, by setting the timings appropriately. For example in the illustration below, the mold is heated while it is closed (illustrated by the red 15s):

where A is the injection molding cycle, as programmed in the Process Settings dialog, and B is the mold rapid heating and cooling settings, as programmed in the Rapid Heating and Cooling inlet dialog. (1) is cycle 1; (2) is cycle 2; (3) is cycle 3; (a) is mold open; (b) is mold close; (c) is when coolant enters the cooling channels.

Example programming, A, for three injection molding cycles with simultaneous mold heating and cooling, B.

In the illustration above, the injection molding cycle, A, as programmed in the Process Settings Wizard dialog, starts with an

Injection+packing+cooling time of 15 seconds (s). The

Injection+packing+cooling time of 15 seconds (s). The  Mold-open time is 2s, during which time the part is ejected, then the mold closes again. Once the mold has closed, a 15s

Mold-open time is 2s, during which time the part is ejected, then the mold closes again. Once the mold has closed, a 15s  Mold-close time before injection delay is programmed, then the cycle repeats itself.

Mold-close time before injection delay is programmed, then the cycle repeats itself. Meanwhile, in the Rapid Heating and Cooling inlet programming, B, when the mold opens at point (a), there is a Secondary air purge for 2s to clear the cooling channels of coolant prior to heating. The mold closes at (b), and heating fluid enters the channels for 15s during the Mold-close time before injection delay. While cycle 2 of the injection molding process commences with Injection+Packing+Cooling time, the coolant lines undergo a Primary air purge for 2s to remove all traces of heating fluid, then coolant enters the cooling channels for the final 13s of the Injection+Packing+Cooling time.

- Temperature controlled

- In this mode, the mold is heated or cooled until it reaches a specific temperature, as measured at a specific node. If it takes longer to reach the specified temperature than you have allowed in your injection molding cycle, as programmed in the Process Settings Wizard, you can choose to:

- Extend the mold open time - In this case, the mold is heated while it is open. Once the set temperature has been reached, the mold will close and the cycle will continue,

- Extend mold-close time before injection - In this case, the mold is heated while it is closed. Once the set temperature has been reached, the cycle will continue,

- Do not delay injection - In this case the next cycle will start, despite the fact that the set temperature has not been reached.

Mold-open time will always correspond to the Secondary air purge.

Mold-open time will always correspond to the Secondary air purge.