Current Results

When you select Results Inquire  Inquire

Inquire  Current Results, the Inquire: Results dialog box appears. Depending on the type of result being displayed, select nodes, elements, or faces to display the current result. You can make your selection either before or after clicking the Current Results command.

Current Results, the Inquire: Results dialog box appears. Depending on the type of result being displayed, select nodes, elements, or faces to display the current result. You can make your selection either before or after clicking the Current Results command.

Results and additional data shown for each entity type:

- Nodes: Displacements, stress, temperature, and other available results include the following data:

- Coordinates of the node (both undisplaced and displaced coordinates, if appropriate)

- The elements in which the nodes are used (when displaying an element-based result, such as stress),

- The current result contour value.

- Elements: Heat flux and other available results include:

- The element number

- The current result contour value.

- Faces Heat flow rate and other available results include:

- The element and face number

- The current result contour value.

The results include the effects of all smoothing settings. As you click a different object (nodes or elements or faces), the information in the Inquire: Results dialog box update to reflect the currently selected object. If you hold down the Ctrl key, the information for the next item will be added (in ascending order) to the current display.

- Select an item

- Right-click

- Access the Select Related fly-out menu

- Choose the related entities to be selected.

For example, if you wish to sum the nodal reaction forces on a particular surface, select the surface, right-click, and choose Select Related Nodes. Then, use the Results Inquire

Nodes. Then, use the Results Inquire  Inquire

Inquire  Current Results command. Finally, choose the Sum option from the Summary drop-down menu. (See the "Summary" bullet below.)

Current Results command. Finally, choose the Sum option from the Summary drop-down menu. (See the "Summary" bullet below.)

Also see the page Results Environment for a discussion of how the results are displayed based on various settings. Examples include node-based versus element-based results, hidden versus not hidden elements, smoothing on versus smoothing off, and so on.

- Summary: By changing the option in the Summary drop-down box, you can have the results for the currently selected nodes manipulated by several methods. The available options are the following:

- None: Displays no summary result.

- Maximum: Displays the maximum result. By definition, a positive value is larger than a negative value, so the positive value would be displayed regardless of the magnitudes.

- Maximum Magnitude: Displays the value for the result with the maximum magnitude. For example, if the results of two selected nodes are 0 and -5, -5 would be displayed in the summary.

- Mean: Displays the arithmetic average of the results, the sum of Ri divided by number of nodes. (see Definitions below.)

- Minimum: Displays the minimum result. By definition, a negative value is smaller than a positive value, so the negative value would be displayed.

- Range: Displays the result of the maximum value minus the minimum value.

- Sum. Adds the selected results. This is especially useful when you want to sum the reaction forces over several nodes or when you want to sum the total heat flow through a certain area of a heat transfer model.

- Mean Weighted By Volume: Displays the average of the results for the selected elements, weighted by the volume of the elements, the sum of (Ri x Vi) divided by sum of Vi. (see Definitions below.)

- Mean Weighted By Mass: Displays the average of the results for the selected elements, weighted by the mass of the elements, the sum of (Ri x mi) divided by sum of mi. (see Definitions below.)

- Equilibrium Temperature: Displays the average temperature of the selected elements, weighted by mass and specific heat. To compute this summary result, the analysis type must be a heat transfer analysis, the results display must be set to temperature, and the material properties need to include the mass density and specific heat. In most situations, the equilibrium temperature can relate to the enthalpy of the part or system; thus, calculating the equilibrium temperature at two states is equivalent to calculating the change in enthalpy.

The equilibrium temperature can be thought of as the temperature at which the selected elements would obtain if they were allowed to come to equilibrium, without losing any heat to the environment. It is based on the following methodology:

integral of (mi x Cpi x dT) divided by integral of (mi x Cpi), both integrated over the range of Ti to Tequil.

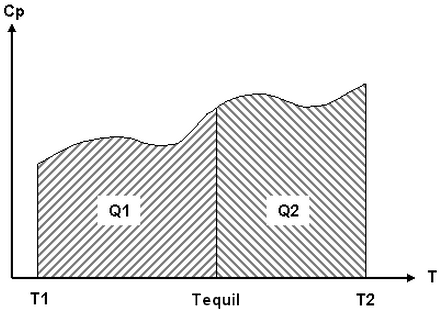

This is easy to visualize for a two mass system. The heat lost by one mass (integral of m2 x Cp2 x dT over the range T2 to Tequil) is equal to the heat gained by the other mass (integral of m1 x Cp1 x dT over the range of T1 to Tequil), so the areas under the graph of specific heat versus temperature are equal. See Figure 1.

Figure 1: Equilibrium Temperature Calculation for Two Masses

The equilibrium temperature Tequil is the temperature at which the amount of heat lost by one mass, Q2, equals the heat gained by another mass, Q1. The area under the curve of the specific heat Cp versus the temperature T is equal for Q1 and Q2.

Definitions used in the summary calculations

- Cpi is the specific heat of the element at node i. Naturally, the specific heat must have been entered in the material properties in order for this calculation to give a meaningful result.

- mi is the mass of the element at node i. The mass of the element is assumed to be equally distributed to all the nodes. Naturally, the mass density must have been entered in the material properties in order for this calculation to give a meaningful result.

- Ri is the result at node i.

- Tequil is the equilibrium temperature.

- Ti is the temperature at node i.

- Vi is the volume of the element at node i. The volume of the element is assumed to be equally distributed to all the nodes on the element.

Note:- For the options that require elements to be selected, all of the nodes on the selected elements are displayed in the Inquire: Results dialog box, and therefore considered in the summary calculation.

- Shape functions are not used in computing the weighted results or the equilibrium temperature. The mass, volume, specific heat, and result are simply divided equally among the nodes of the element. For elements without midside nodes, this method will produce accurate results. For elements with midside nodes, the results are reasonable.

- The weighted results for composite elements are based on the mass and volume of the entire element, not on each layer individually. When viewing the results of a single layer, the weighted result may not be meaningful.

- Include results from hidden elements: When displaying an element-based result, such as stress, the Inquire: Results window lists the elements that share the selected node. When the Include results from hidden elements check box is activated, the list of elements include both visible and hidden elements, and therefore the Current Result Value shown also includes the contribution from these hidden elements. When the Include results from hidden elements option is deactivated (unchecked), the list of elements and the current result value are based on the visible elements only.

- Clear: Pressing this button will clear the current information from the Inquire: Results screen. However, it does not clear the selection set from the display area.

- Save Values: This option allows you to save the current data to a text file. The .out format will create a text file similar in format to the Inquire: Results dialog box. The .csv format creates a comma-separated values file, where each item on the row is separated by a comma. This format is convenient for importing into a spreadsheet and using the data for other purposes.

The Export Results dialog box appears when Save Values is clicked. Choose the file name and location of the exported results. Activate the Append check box on the Export Results dialog box before clicking Save to append the current results to an existing file. Otherwise, the existing file will be overwritten with the current results.

- Save To Report: This option is similar to the Save Values command in that the results shown in the Inquire: Results window are saved to a text file. The differences are as follows:

- You can only specify the name of the file. You cannot specify the location.

- The filename extension is .out.

- The location is set to the ds_inquired_results subfolder associated with the current design scenario.

- The text file is appended to the Report. In the Configure Report window, the saved results appear at the bottom of the report tree, but you can drag the heading to reorder the report contents.

- Specify: Click this button to numerically specify items for which you want to display the results. The following types of specifications are supported (depending upon the results type):

- Part Number and Element Number: When viewing element and face-based results, the Specify dialog box prompts you for a part number and element number. The element number can include multiple elements by separating them with a comma (,). For example, entering the text 1, 14, 21 in the Element Number field produces the results for element numbers 1, 14, and 21.

- Node Number(s): When viewing nodal-based results, this option allows you to enter one or more node numbers for which to view the results. Separate multiple nodes with a comma (,). For example, entering the text 1, 14, 21 in the Node Number(s) field produces the results for node numbers 1, 14, and 21.

- Location: When viewing nodal-based results, this option allows you to enter a coordinate (X, Y, and Z) and Radius. All nodes within a sphere or this radius around the specified coordinate are selected. A Radius of zero (0) selects the closest node to the specified coordinate.

Note:- For stress models, displaying the displaced model and exaggerating the displacement scale factor affects whether a node is within the radius of the specified location. Displaying the displaced shape and exaggerating the displacement scale changes the position of the nodes relative to the specified location. (The displacement scale is controlled by Results Contours

Displacement

Displacement  Show Displaced

Show Displaced  Displaced Options

Displaced Options  Scale Factor.) In this regard, the Location option is no different than drawing a 3D selection sphere in the display area (if such a capability existed). Nodes that appear inside the sphere are selected.

Scale Factor.) In this regard, the Location option is no different than drawing a 3D selection sphere in the display area (if such a capability existed). Nodes that appear inside the sphere are selected. - Set the displacement scale factor to As an Absolute Value and enter a Scale Factor of 1 to select nodes whose displaced positions are actually within the radius of the specified location.

The specified nodes or elements are highlighted in the model, just as if you selected the objects with the mouse. Displaying an unshaded view of the feature lines (View

Appearance

Appearance  Visual Style

Visual Style  Features) can help show where the highlighted objects are in the model.

Features) can help show where the highlighted objects are in the model. - To Inquire about Boundary Element results: First, select any one of the following result types:

-

Results Contours

Other Results

Other Results  Element Forces

Element Forces  Axial Force

Axial Force

-

Results Contours

Other Results

Other Results  Element Forces

Element Forces  Axial Moment

Axial Moment

-

Results Contours

Other Results

Other Results  Element Displacements

Element Displacements  Stretch

Stretch

-

Results Contours

Other Results

Other Results  Element Displacements

Element Displacements  Twist

Twist

You can inquire on the results for a boundary element by inquiring on the model node to which the boundary element is attached. The Inquire: Results dialog box lists the results for each element in each part of the model that is connected at that node. To determine which part contains the boundary elements, use Results Inquire

Inquire

Inquire  Model Statistics. The element type for each part and the number of elements in each part are listed. To determine which element number corresponds to which boundary element, use Results Inquire

Model Statistics. The element type for each part and the number of elements in each part are listed. To determine which element number corresponds to which boundary element, use Results Inquire  Inquire … Element Information. Press the Specify button, type the part number of the boundary elements in the Part Number field, and type a valid element number in the Element Number field. The specified boundary element is highlighted in the display area. This technique is useful when more than one boundary element is located at a single node.

Inquire … Element Information. Press the Specify button, type the part number of the boundary elements in the Part Number field, and type a valid element number in the Element Number field. The specified boundary element is highlighted in the display area. This technique is useful when more than one boundary element is located at a single node. -

Results Contours

Results by Part

When you select this command, the Inquire Results by Part dialog box appears. A list of the active parts in the model appears in the top half of the dialog box, with a checkbox next to each part. All parts are selected by default. Deselect any parts you do not want included in the Inquire Results by Part output. Select All and Select None buttons are provided to facilitate the part selection process when you want to toggle the inclusion state of the majority of parts. After changing the number of active parts, click Inquire to update the current results list in the bottom half of the dialog box.

Items the Inquire Results by Part Output:

- Result Type: This label is based on the currently displayed contour plot.

- Smoothing Function: Indicates the Smoothing Function applied to the current results (such as, Mean, Maximum Magnitude, Minimum, or None ).

- Interior Results: Indicates whether internal results are included. The inclusion or exclusion of internal results is determined by the state of the Show Internal Mesh option. This option is located in the View panel of the Results Options tab.

- Units: The units of the results, based on the current model display units.

- Load Case, Time Step, or Mode: Depending upon the type of analysis, either the load case, time step, or mode number will be displayed, whichever is applicable. The Results by Part output is based on the currently displayed load case, time step, or mode. Note: When the display shows the resultant of multiple modes, such as are shown by default for response spectrum or random vibration analyses, this line will be omitted from the Results by Part output.

- Minimum Value and Maximum Value: A table lists the minimum and maximum values of the current results for each part selected within the Inquire Results by Part dialog box. In addition, the Location data for the maximum and minimum values is reported, as follows:

- NodeNum: The node number where the maximum or minimum value occurs.

- X, Y, and Z:. The coordinates of the node, based on the global coordinate system.

To Save Inquire Results by Part Output:

- Save Values: This option allows you to save the current data to a text file. The .out format will create a text file similar in format to the Inquire: Results dialog box. The .csv format creates a comma-separated values file, where each item on the row is separated by a comma. This format is convenient for importing into a spreadsheet and using the data for other purposes.

The Export Results dialog box appears when Save Values is clicked. Choose the file name and location of the exported results. Activate the Append check box on the Export Results dialog box before clicking Save to append the current results to an existing file. Otherwise, the existing file will be overwritten with the current results.

- Save To Report: This option is similar to the Save Values command in that the results shown in the Inquire Results by Part window are saved to a text file. The differences are as follows:

- You can only specify the name of the file. You cannot specify the location.

- The filename extension is .out.

- The location is set to the ds_inquired_results subfolder associated with the current design scenario.

- The text file is appended to the Report. In the Configure Report window, the saved results appear at the bottom of the report tree, but you can drag the heading to reorder the report contents.

Loads and Constraints

When you select this command, the Inquire: Loads and Constraints dialog will appear. Use Selection  Select

Select  Loads Constraints to limit your selection to the load and constraint objects. To further limit the selection, use the Selection

Loads Constraints to limit your selection to the load and constraint objects. To further limit the selection, use the Selection  Filter to select which loads and constraints will be available for selection. You can select on any load or constraint and the type of load or constraint, the node or element to which it is applied, the coordinates, and the relevant information will be displayed in the Inquire: Loads and Constraints dialog box. As you click more loads or constraints the information in this screen will update to reflect the current selected object. If you hold down the Ctrl key, the information for the next object will be appended to the current display.

Filter to select which loads and constraints will be available for selection. You can select on any load or constraint and the type of load or constraint, the node or element to which it is applied, the coordinates, and the relevant information will be displayed in the Inquire: Loads and Constraints dialog box. As you click more loads or constraints the information in this screen will update to reflect the current selected object. If you hold down the Ctrl key, the information for the next object will be appended to the current display.

Distance and Angle

When you select this command, the Inquire: Distance and Angle screen will appear. This screen gives the following information by clicking on successive points:

- Clicking on two points will give the total distance between the points.

- Clicking on three points (which forms two vectors) will give the angle between the two vectors.

- Clicking on four points (which forms a quad region) will give the fold angle of the quad. Be sure to click in a consistent direction to measure the warp angle: click either clockwise or counter-clockwise. The Fold Angle 1 is calculated by the angle between the vectors normal to the two triangles created by dividing the quadrilateral with a line from the second node selected to the fourth node selected. The Fold Angle 2 is calculated in the same manner but divides the quadrilateral from the first node selected to the third node selected.

Maximum Results Summary

When you select this command, the Inquire: Maximum Results Summary dialog will appear. The dialog window will contain the maximum result, based on the current result contour being displayed, for all nodes in the model, for all load cases or time steps. All nodes includes nodes on hidden parts, on hidden elements, and in the interior of solid or brick element parts. The results are sorted in descending order based on the value of the result.

- Clear Contents: Pressing this button will clear the current information from the Inquire: Maximum Results Summary dialog.

- Save Values: This option will allow you to save the current data to a text file. The .out format will create a text file similar in format to the Inquire: Maximum Results Summary dialog. The .csv format will create a comma separated value file where each item on the row is separated by a comma; this format is convenient for importing into a spreadsheet and using the data for other purposes.

The Export Results dialog will appear when the Save Values button is clicked. Choose the file name and location of the exported results. Activate the Append check box on the Export Results dialog before clicking the Save button to append the current results to an existing file. Otherwise, the existing file will be overwritten with the current results.

Detailed Beam Stress and Strain

When an MES or nonlinear beam element is selected, the Inquire panel includes the options Detailed Beam Stress and Detailed Beam Strain. These commands give the stresses and strains calculated by the processor.

Stress

Stress Beam and Truss commands are only partially corrected by the yield strength. Each of the stresses (axial stress, bending stress in local 2, and bending stress in local 3) are capped or limited to the yield stress if necessary. The worst stress then adds the three results together.

Beam and Truss commands are only partially corrected by the yield strength. Each of the stresses (axial stress, bending stress in local 2, and bending stress in local 3) are capped or limited to the yield stress if necessary. The worst stress then adds the three results together. The format of the information in the Inquire Detailed Beam Stress dialog is as follows:

Part Element Section Intx Inty Intz State S1-1 S1-2 S1-3

where

- Part is the part number

- Element is the element number

- Section is the section number (when cross section is treated as a series of rectangles)

- Intx is the integration point in axial direction (local x-dir or 1 axis) and increments from 1 through the integration order set by the user (7 maximum)

- Inty is the integration point in local y-dir (2 axis) and increments from 1 through the integration order set by the user (7 maximum)

- Intz is the integration point in local z-dir (3 axis) and increments from 1 through the integration order set by the user (7 maximum)

- State indicates whether the point is elastic or plastic

- S1-1 is the normal stress or strain in the 11 direction

- S1-2 is the shear stress or strain in the 12 direction

- S1-3 is the shear stress or strain in the 13 direction

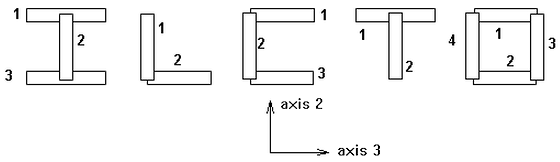

Imagine the beam element composed of numerous integration points in all three directions (axis 1 along the length, axes 2 and 3 in the plane of the cross section). The stress and strain output is given at all the integration points, so with the integration order set to 2x2x2, each element would output 8 lines of results for each element.

Find the 3D position (X, Y, Z) of the integration point (Intx, Inty, Intz) within the element. This is done with the following calculations depending on the shape.

Rectangle

Y = C(Inty,TINTy)*height*0.5, measured from the neutral axis in the direction of axis 2

Z = C(Intz,TINTz)*width*0.5, measured from the neutral axis in the direction of axis 3

Circle

R = radius/2

R = R + C(Inty,TINTy)*R and Shear and Moment Diagrams

α = (2π/TINTz)*(Intz-1)

Y = R*cos(α), measured from the neutral axis in the direction of axis 2

Z = R*sin(α), measured from the neutral axis in the direction of axis 3

Hollow circle

R = (Ro+Ri)/2

R = R + C(Inty,TINTy)*(Ro-Ri)/2

α = (2π/TINTz)*(Intz-1)

Y = R*cos(α), measured from the neutral axis in the direction of axis 2

Z = R*sin(α), measured from the neutral axis in the direction of axis 3

where

- X = C(Intx,TINTx)*0.5*Length+0.5*Length, measured from node i (= node 1)

- TINTx is the total number of integration points in x-dir (Integration Order in local 1 axis)

- TINTy is the total number of integration points in y-dir (Integration Order in local 2 axis)

- TINTz is the total number of integration points in z-dir (Integration Order in local 3 axis)

and the quantity C(i, Integration Order) is from the following table:

| Integration Order | C(i, Integration Order) | ||||||

|---|---|---|---|---|---|---|---|

| i = 1 | i = 2 | i = 3 | i = 4 | i = 5 | i = 6 | i = 7 | |

| 1 | 0 | - | - | - | - | - | - |

| 2 | -1 | 1 | - | - | - | - | - |

| 3 | -1 | 0 | 1 | - | - | - | - |

| 4 | -1 | -0.333 | 0.333 | 1 | - | - | - |

| 5 | -1 | -0.5 | 0 | 0.5 | 1 | - | - |

| 6 | -1 | -0.6 | -0.2 | 0.2 | 0.6 | 1 | - |

| 7 | -1 | -0.666 | -0.333 | 0 | 0.333 | 0.666 | 1 |

General cross section

Each section is treated as an independent quadrangle separately. C(i,j) can be directly applied to find the position.

Predefined cross section

Each section is treated like an independent quadrangle separately as below, with the section number indicated.

Model Statistics

When you select this command, the Inquire: Model Statistics dialog box will appear. The number of nodes, elements, load cases and parts will be displayed in the dialog. In addition the details for each part will be shown.

Element Information

When you select this command, the Inquire: Element Information dialog box will appear. You can select any element and the element number, element, type, and the nodes that create this element will be displayed in the screen. As you click more elements, the information in this screen will update to reflect the currently selected element. If you hold down the Ctrl key, the information for the next element will be appended to the current display.

Pressing the Specify button will allow you to enter a part number and element number for which to view the element information. Multiple elements can be entered by separating them with a comma (,). For example, entering the text 1, 14, 21 (without the quotation marks) for the Element Number field will select the element numbers 1, 14, and 21 in the designated part.

The element or elements will be highlighted in the model just as if you selected the elements with the mouse. Displaying an unshaded view of the feature lines (View: Display: Features) can help show where the highlighted elements are in the model.

Adding Shear and Moment Diagrams

When beam elements are selected in a stress analysis, the following commands are available in the Results Inquire tab, Graphs panel to draw shear and moment diagrams:

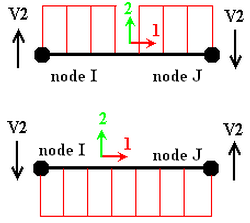

- Add Shear Diagrams (Axis 2): This command will display the diagram of the shear forces along the local axis 2 direction. The diagram is plotted in the plane formed by element axes 1 and 2.

- Add Shear Diagrams (Axis 3): This command will display the diagram of the shear forces along the local axis 3 direction. The diagram is plotted in the plane formed by element axes 1 and 3.

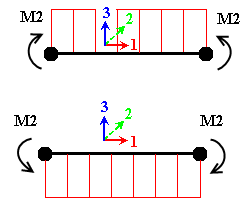

- Add Moment Diagrams (Axis 2): This command will display the diagram of the bending moment about the local axis 2 direction. The diagram is plotted in the plane formed by element axes 1 and 3.

- Add Moment Diagrams (Axis 3): This command will display the diagram of the bending moment about the local axis 3 direction. The diagram is plotted in the plane formed by element axes 1 and 2.

- Clear Beam Diagrams: This command will clear the shear and/or moment diagrams from the selected beam elements.

The diagrams are drawn or removed from the selected beam elements only; other diagrams in the model are not affected. The two shear diagrams cannot be shown simultaneously on the same element, nor can the two moment diagrams be displayed on the same element. One shear and one moment diagram can be shown on the same element.

The direction of the shear and moment diagrams follow the convention shown in the following figures. In the figures, keep in mind that the sign of the values (V2 for shear or M2 for moment) follow the conventions described in the paragraph Element Forces and Moments on the page: Linear Results.

|

|

|

Direction of the Shear Diagram. The arrow at node I controls on which side of the element the diagram is drawn. The shear in the direction of axis 2 is drawn in the plane of axes 1 and 2 (shown above); the shear for axis 3 is drawn in the plane of axes 1 and 3. |

Direction of the Moment Diagram. The arrows control on which side of the element the diagram is drawn. The moment about axis 2 is drawn in the plane of axes 1 and 3 (shown above); the moment about axis 3 is drawn in the plane of axes 1 and 2. |

Options

Options  Results

Results  Individual FEA Object Settings to set the color of the Moment Diagram or Shear Diagram.

Individual FEA Object Settings to set the color of the Moment Diagram or Shear Diagram. Average Film Coefficient

This command is only available for thermal analyses. When this command is selected, the Inquire: Average Film Coefficient dialog will appear.

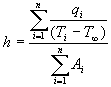

You can select one or multiple faces of the model. The screen will report the faces that are selected and the average film coefficient, h, over those faces. The equation used to calculate h is:

Where: h = Average film coefficient

q = Heat rate of face through face i

Ti = Average temperature of the nodes that define face i

![]() = Ambient temperature which must be defined by pressing the Ambient Temperature button

= Ambient temperature which must be defined by pressing the Ambient Temperature button

Ai = Area of face i

Probes Panel

Th Probe command will activate probe mode. As you move the mouse over the model, a probe will appear displaying the current result value for that node, element or face (depending on the selection method). If you want the probe to remain on a node, right-click in the display area and select the Add Probe command.

- Also see the page Results Environment for a discussion of how the results are displayed based on various settings.

- The number of decimal points displayed by the probe can be controlled from the Result Contours

Settings

Settings  Legend Properties

Legend Properties  Probe Settings command. See the page: Probe Settings Tab for details.

Probe Settings command. See the page: Probe Settings Tab for details.

The Maximum and Minimum commands display a pointer at the nodes with the maximum and minimum current result value, respectively. Optionally, activate the Minimum Maximum Nodes option to append the node number to each probe. This option is in the pull-out section of the Probes panel.

Lastly, in the pull-out section of the Probes panel, there is a Contact Diagnostic Probes option, which is enabled by default. These diagnostic probes indicate where penetration or chatter are occurring during a surface contact analysis. Click this option to toggle the visibility of the contact diagnostic probes.