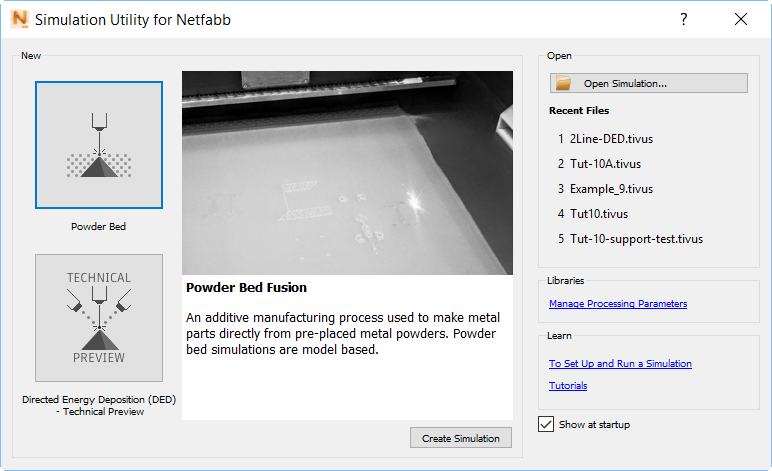

An overview of how to use Autodesk Simulation Utility for Netfabb and where to get more information.

How to set up a part-scale powder bed fusion simulation

- On the Simulation menu, review and adjust

Simulation settings as necessary.

- Create a new simulation project and select

Powder Bed Fusion.

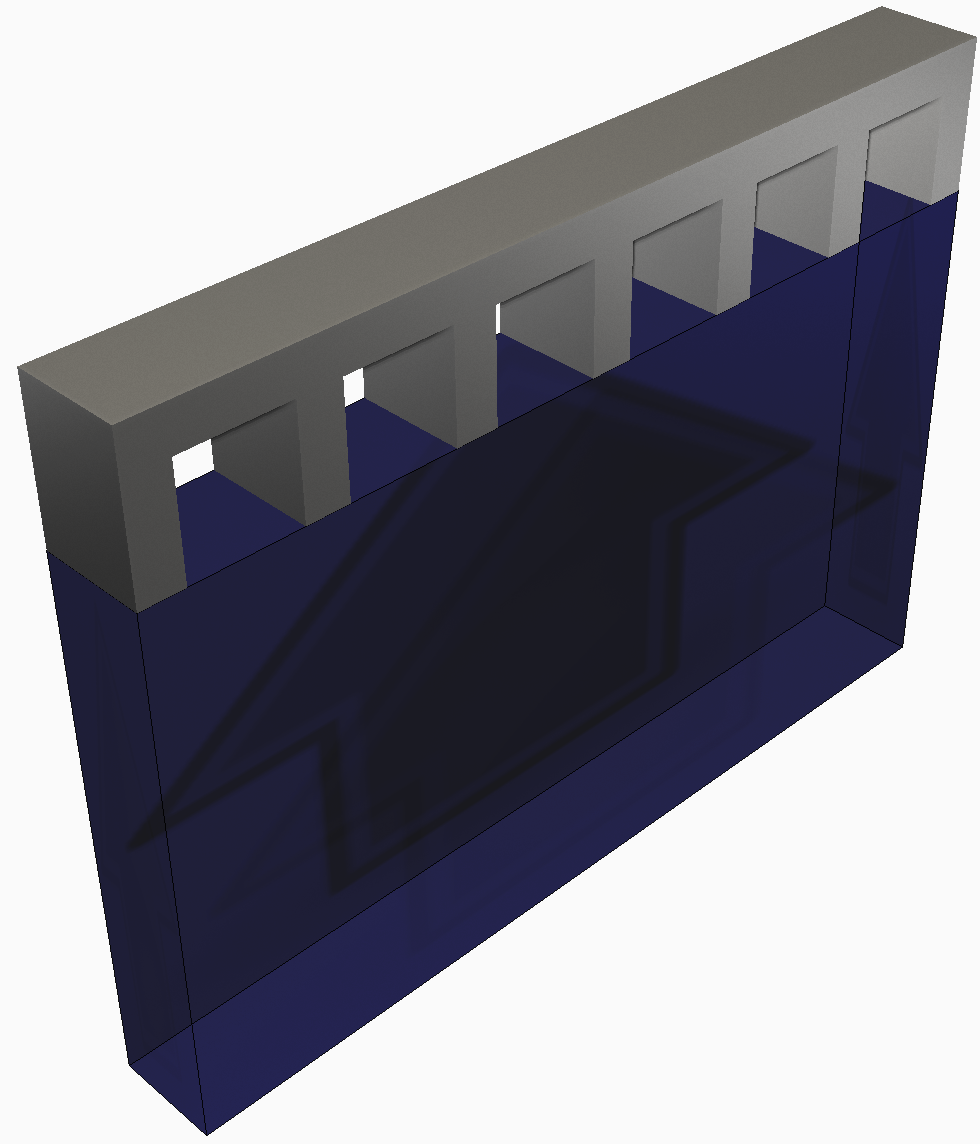

- Import one or more 3D geometric files for which to simulate the additive manufacturing process. One or more additional geometry files may be imported to model support structures.

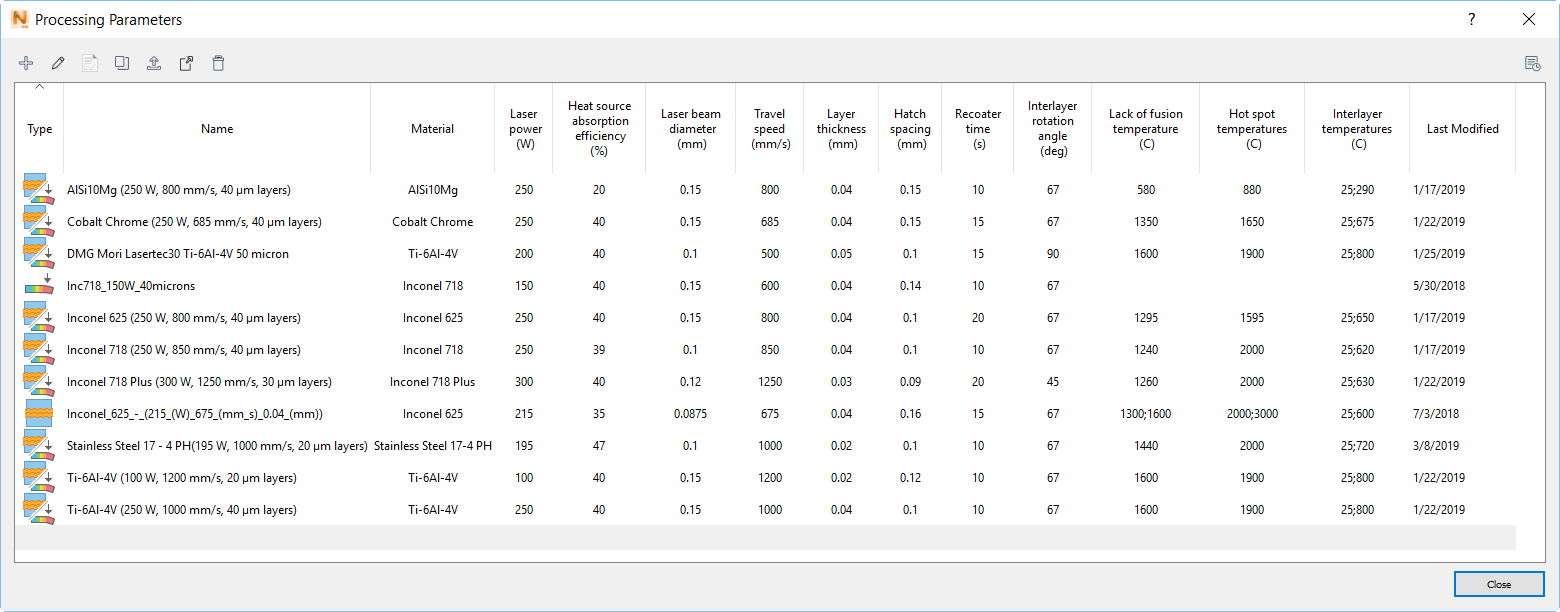

- In the

process parameter (PRM) file library, identify a PRM file that matches the processing parameters and material of the part to simulated, or create a new custom PRM file if none currently exists.

Note: A license of Local Simulation is required to generate new PRM files.

- If necessary,

adjust the orientation of the part by right clicking on the part in the Browser and selecting

Move.

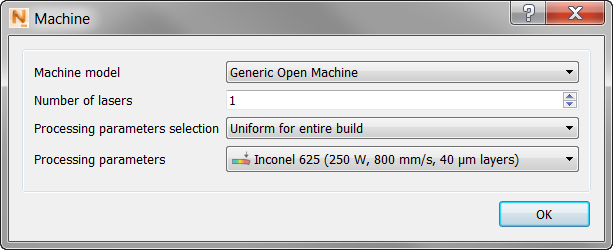

- In the

Machine dialog specify the PRM file for the processing parameters and material of the component.

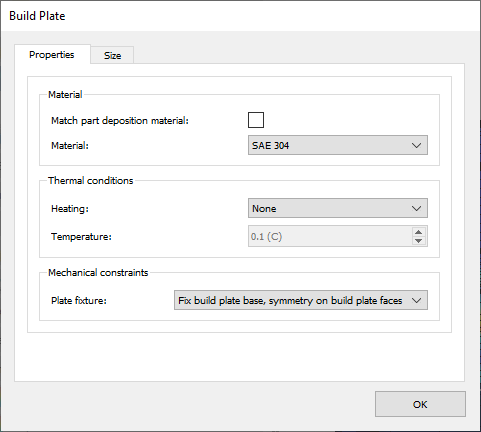

- Use the

Build Plate panel to specify the build plate material, size, build plate heating, and mechanical constraints.

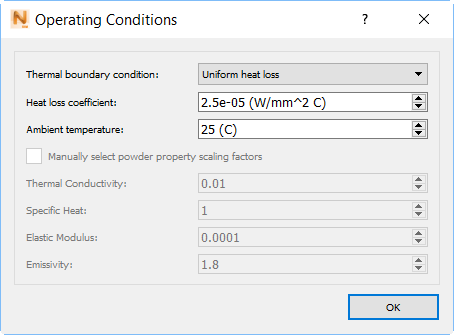

- In the

Operating Conditions dialog, choose the ambient temperature and thermal boundary conditions during processing.

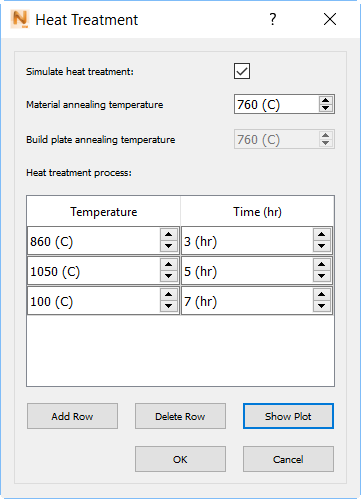

- Use the

Heat Treatment panel to detail the time-temperature values of a stress relief heat treatment cycle, if one is used.

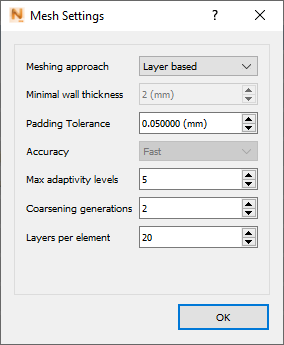

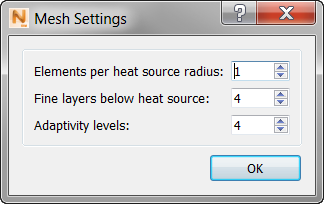

- Select

mesh settings appropriate for the size and complexity of the component.

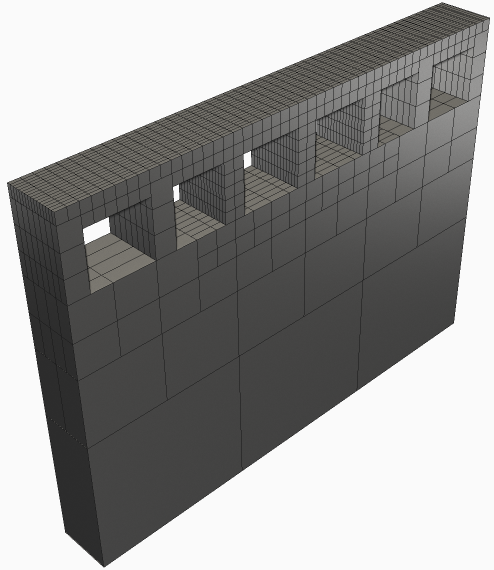

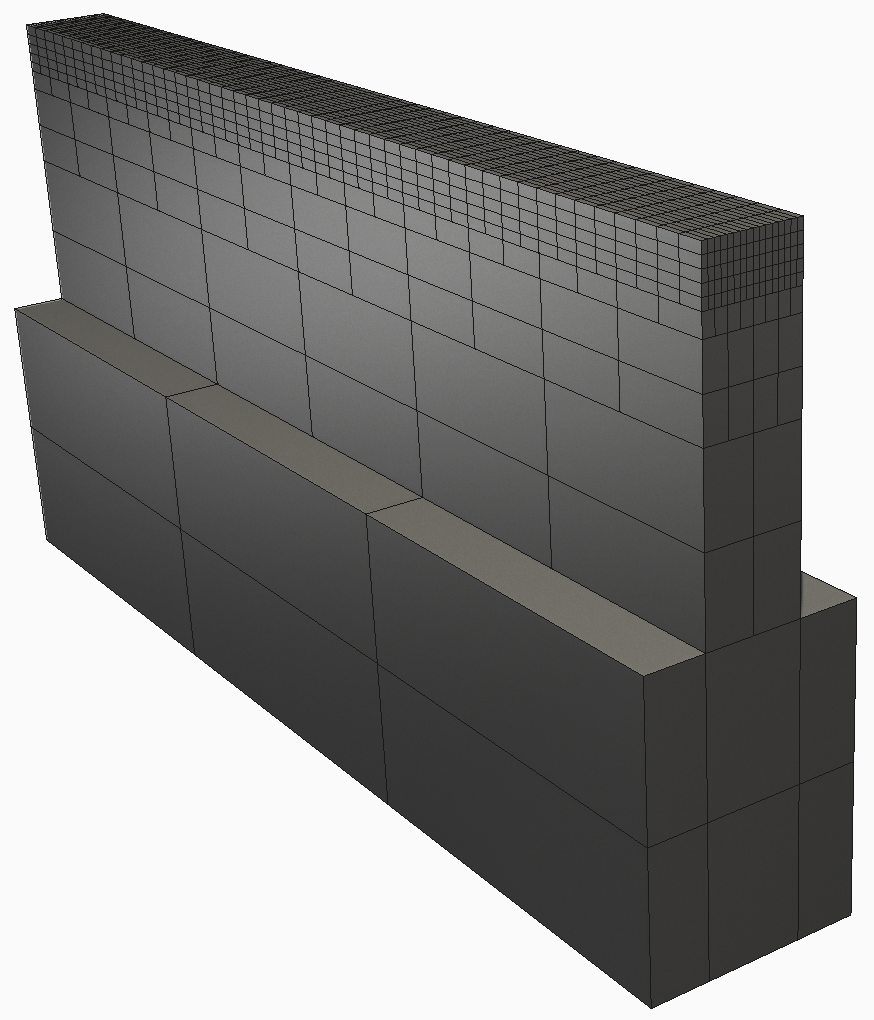

- Generate a

Mesh Preview to ensure adequate voxel representation of the source geometry and to check for flaws in the mesh that could affect simulation results.

- Solve the simulation on the local computer.

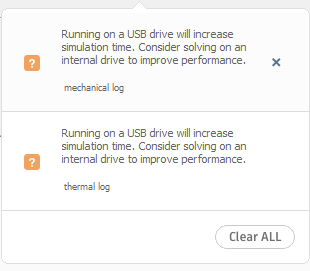

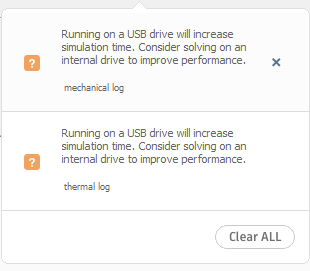

- Reference any notifications in the top right of the screen as they appear or

review the log files for errors or warnings.

- Examine model results.

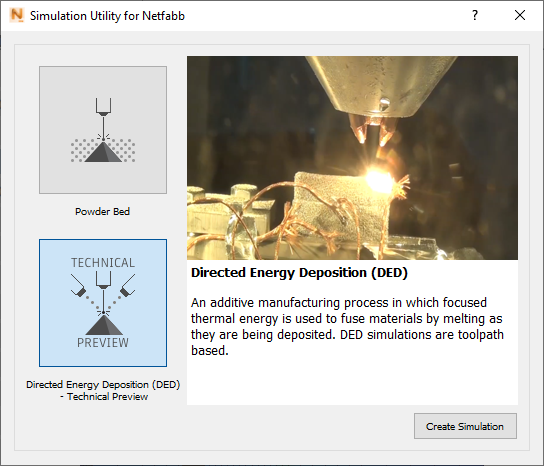

How to set up a directed energy deposition simulation

Note: Simulation Utility LT cannot run directed energy deposition (DED) simulations. These require the full

Simulation Utility, installed with

NetfabbLocal Simulation.

- On the Simulation menu, review and adjust

Simulation Utility settings to suit your project if necessary.

- Create a new simulation project and select Directed Energy Deposition.

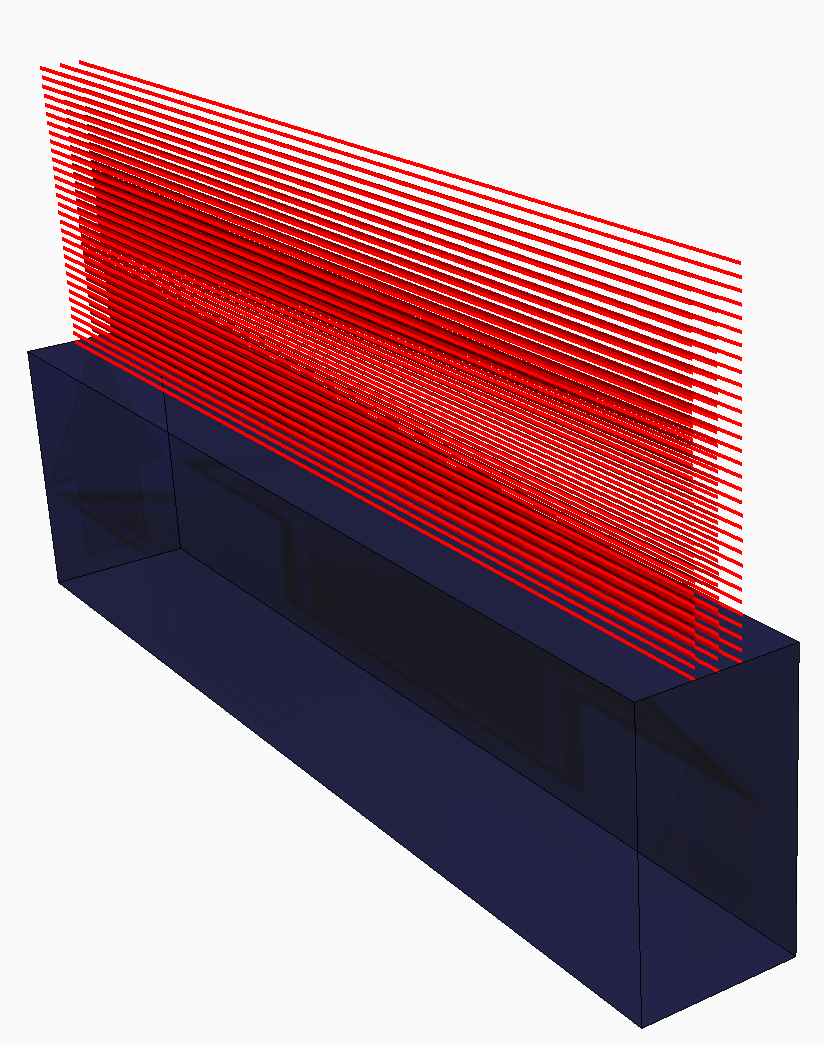

- Import

a laser vector (LSR) file. An LSR file specifies the power, speed, laser spot size, beginning and end points, and timing of the laser vectors to build a DED component.

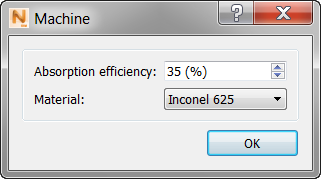

- Specify the material and absorption efficiency on the

Machine panel. Laser based DED systems absorption efficiencies are generally in the range of 30-40%. Electron beam systems typically have much higher absorption efficiencies, between 88-98%

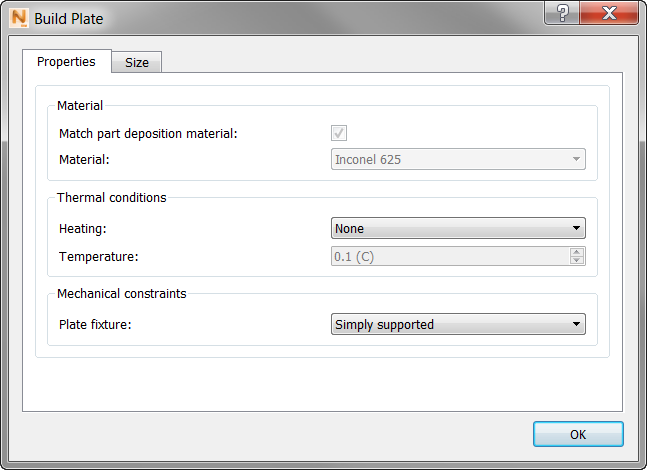

- In the

Build Plate dialog, specify the size, build plate heating, and mechanical constraints.

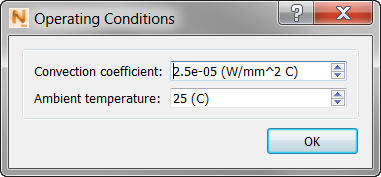

- In the

Operating Conditions dialog, choose the ambient temperature and global convection coefficient during processing.

- Select

mesh settings appropriate for the size and complexity of the component.

- Generate a mesh preview to ensure adequate voxel representation of the source geometry and to check for flaws in the mesh that could affect simulation results.

- Solve the simulation.

- Reference any notifications in the top right of the screen as they appear or

review the log files for errors or warnings.

- Examine model results.

See the Tutorials in the Help for videos and step-by-step walkthroughs of simulation solutions, using sample files that you can download from an Autodesk website.