Swarf cutting calculates toolpaths that cut with the side of the tool and works only on developable surfaces because the tool must be in contact with the surface for the whole cutting depth.

For a tool to swarf cut, it has to be able to have contact with the surface at all points along the cutting edge of the tool. For a non-developable surface, FeatureCAM always leaves material on or produces fragmented toolpaths (rather than gouge). This means that you need to look at parts carefully before trying to swarf cut them. It may be that rotating the part (cutting from the side rather than the top of an aerofoil blade) produces the required result.

Swarf machining makes every attempt to machine the selected surfaces but you may have to consider running more commands including ones with different options for swarf milling to obtain the best machining results.

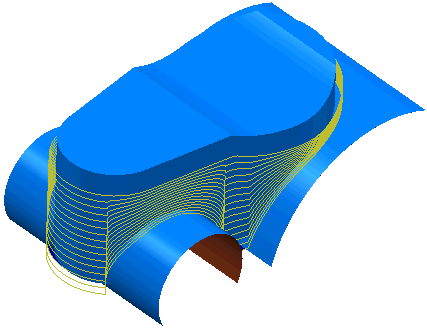

It is possible to identify approximately whether a surface is developable and ruled by shading and also displaying its wire frame geometry within FeatureCAM. You can then orientate the view to be roughly down the expected tool axis vector.

If the surface top edge and the surface bottom edge appear to be parallel at all points, on both edges, and no shaded elements are visible, then the surface is roughly developable and ruled.

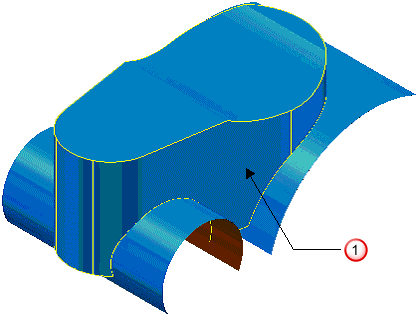

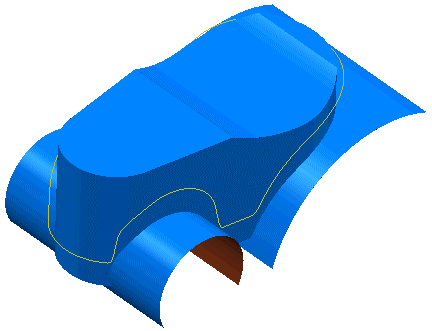

Selected Surface

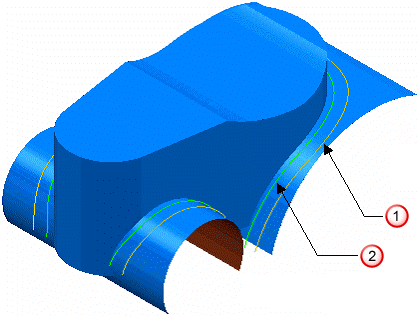

Selected Surface

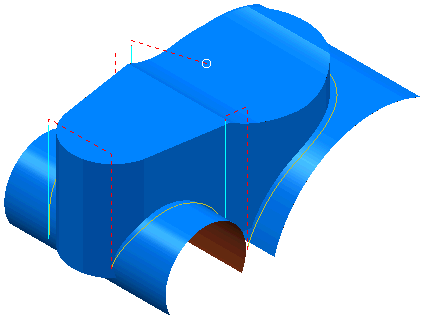

Use the Surface control tab to determine whether you swarf cut:

- on the inside:

- or outside of the surface:

On theMilling tab you can set:

-

Axial offset

— offsets the lowest position of the toolpath along the tool axis.

-

Leave allowance

— specifies the amount of stock material to leave after the cut.

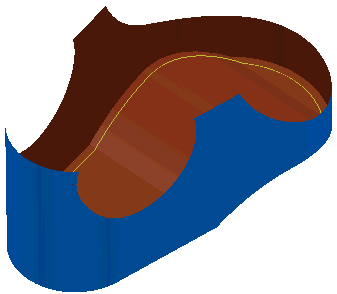

Using

Leave allowance

Using

Leave allowance

No

Leave allowance

No

Leave allowance

-

Multiple Cuts — This allows multiple toolpaths with a Z-increment setting.