Remachining is used to automatically mill regions that were not cut by previous operations. Planar remachining can be performed with a Parallel, Z finish, or 3D spiral toolpath.

You specify the diameter of the previous tool that was used to cut the part and FeatureCAM automatically determines the uncut regions and applies a toolpath to them.

Remachining is useful for:

- Remove material that could not be reached with a larger tool for both finishing and roughing.

- Pre-relieve corners roughed with a larger tool for high speed finishing with a smaller tool.

Example

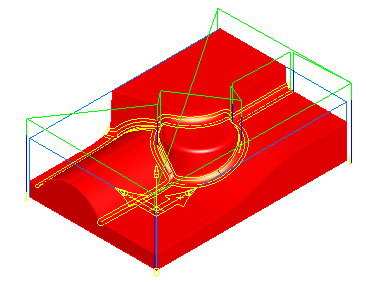

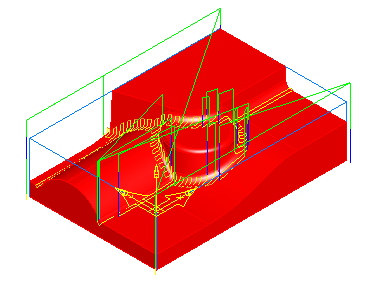

In the example below, the trough region is automatically calculated and the parallel toolpath is limited to this region.

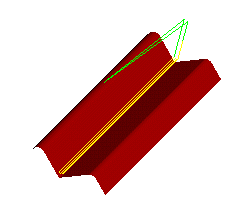

For parallel and Z-level remachining, the previous tool diameter is used to calculate the uncut region and the toolpath is clipped to that region as shown in the figures below.

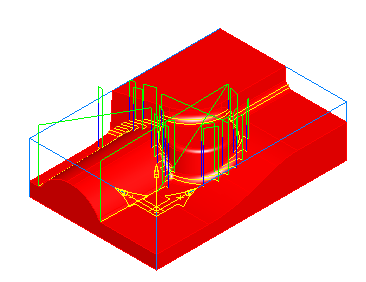

For 3D spiral remachining, the outer boundary of the uncut region is automatically calculated from the previous tool diameter. A toolpath is then created that spirals inward from the boundary. 3D spiral remachining creates a toolpath that is similar to corner remachining, but in some cases, the 3D spiral has fewer retracts.