Use the Advanced Pocket Mill dialog and its associated pages to specify settings for an advanced pocket mill strategy.

Style — Select a style to use for removing material:

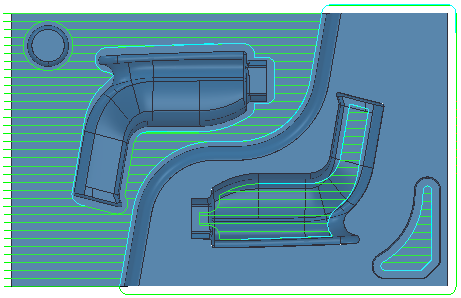

Raster — This comprises straight-line moves parallel to either the X or Y axis.

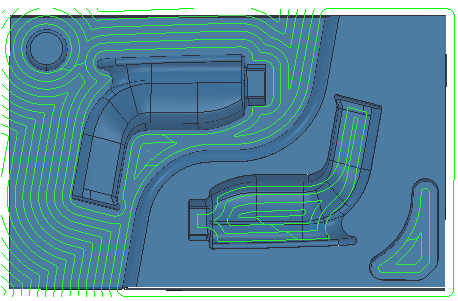

Offset — This clears an area with contours generated by repeatedly offsetting the initial slice until no further offset is possible.

This produces a toolpath that:

- maintains constant tool load and chip production.

- maintains cut direction.

- avoids machining small or thin-walled upstands.

- minimizes full-width cuts.

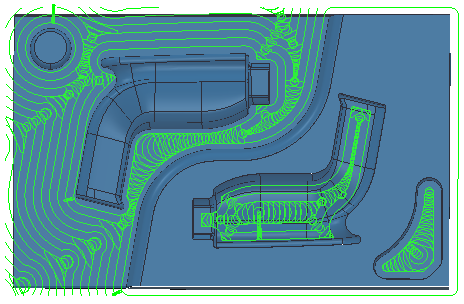

Vortex — This produces an offset toolpath which never exceeds the maximum tool engagement angle for optimum machining. As the tool approaches the maximum engagement angle, the toolpath changes to a trochoidal path to avoid tool overload.

Tolerance — Enter a value to determine how accurately the toolpath follows the contours defined by the model.

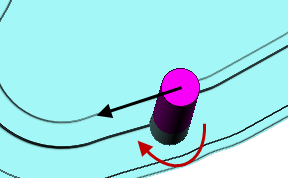

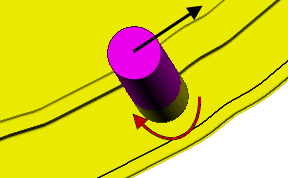

Cut direction —Select a milling style:

-

Climb — Select to create toolpaths using only climb milling, where possible. The tool is on the left of the machined edge when viewed in the direction of tool travel.

-

Conventional — Select to create toolpaths using only conventional or upcut milling, where possible. The tool is on the right of the machined edge when viewed in the direction of tool travel.

- Any — Select to create toolpaths using both conventional and climb milling, as appropriate. This minimizes the tool lifts and tool travel.

Pocketing Side — Specify how profiles are used for identifying regions for machining.

- Inside Profile — Outer profiles are considered pocket walls, and nested curves are islands. This is the default setting.

- Outside Profile — All profiles are considered islands and nested curves are ignored.