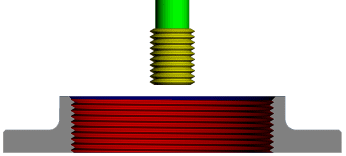

The Thread milling is a cycle similar to reverse helical but with improved leads in and out for thread creation.

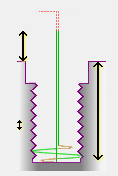

By default, with a milling direction of Up, the tool:

- Plunges to just below the thread depth.

- Leads in using a straight line in the plane normal to the hole axis followed by a helix, using the thread pitch.

- The thread is cut with a 360

helical move, moving up by the pitch.

helical move, moving up by the pitch. - A lead out reversing the lead in.

- Retract to Safe Z.

With a milling direction of Down, then:

- The lead in starts at the chosen start height.

- The thread is cut with a 360

helical move, moving down by the pitch.

helical move, moving down by the pitch.

Note: You can create a thread milling toolpath in a tapered hole.

There are several pages associated with the Thread milling strategy:

- Drilling — The main page used to define a thread milling toolpath.

- Retraction — Settings to control how far the thread tool retracts between pecks.

- Draft — Settings to create a tapered hole using a tool smaller than the hole.

- Threading — Settings for thread creation.

- Order — Settings to control the order of machining.

- Automatic verification — Settings to automatically verify the toolpath when calculating it.

For more information on the Strategy Selector dialog, see Toolpath Strategies.

The common tabs are described in common toolpath strategy pages.