Lead out controls the movement of the tool after it leaves the stock, at the end of a cutting move.

You can select a 2nd choice for the Lead out which is used if your 1st choice gouges.

This page contains the following:

Choice — Select the type of move to use before each cutting move.

Linear move — Enter the length to extend the Lead out move after the cutting move finishes. The distance is the length of the linear tangential move between the arc and cutting portion of the toolpath.

A

Lead out

of

Surface normal arc with a

Distance of

0, an

Angle

of

90 and a

Radius of

5.

A

Lead out

of

Surface normal arc with a

Distance of

0, an

Angle

of

90 and a

Radius of

5.

A

Lead out

of

Surface normal arc with a

Distance of 10, an

Angle

of

90 and a

Radius of

5.

A

Lead out

of

Surface normal arc with a

Distance of 10, an

Angle

of

90 and a

Radius of

5.

Angle — Enter the angle of the Lead out move relative to the toolpath segment. For arcs, this is the angle spanned by the arc. For lines, it is the orientation relative to the cutting move.

Radius — Enter the radius of the Lead out arc move.

Length — Enter the length to extend the Lead out move before the cutting move starts.

Ramp options — Click to display the

Lead Out Ramp Options dialog. This determines how the tool ramps out of the stock.

Ramp options — Click to display the

Lead Out Ramp Options dialog. This determines how the tool ramps out of the stock.

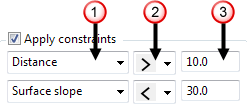

Apply constraints — Select this option to apply constraints to your leads and then select a constraint from the list. Selecting a constraint from the list creates an additional field to apply further constraints. 1st choice and 2nd choice links have a maximum of 2 constraints. If more than one constraint is selected they must all be satisfied for a link to be applied.

To apply constraints:

Select a constraint type from the list:

Select a constraint type from the list:

- Distance — Constrain the link by its distance spanned.

- Surface slope — Constrain the link by the slope angle of the surface at either end of the link.

Select an option from the list to define the constraint limit:

Select an option from the list to define the constraint limit:

-

— The constraint is satisfied if the parameter is less than the specified value.

— The constraint is satisfied if the parameter is less than the specified value.

-

— The constraint is satisfied if the parameter is greater than the specified value.

— The constraint is satisfied if the parameter is greater than the specified value.

Enter the constraint value.

Enter the constraint value.

— Click to copy the

Lead in values to the

Lead out page.

— Click to copy the

Lead in values to the

Lead out page.

— Click to copy the

Lead out values to the

Lead in page.

— Click to copy the

Lead out values to the

Lead in page.

Gouge check — Select this option for PowerMill to gouge-check all leads and links.