Use the options on the Lead outs tab of the Toolpath connections dialog to control the tool's movement at the end of a cutting move.

You can select a 2nd choice for the Lead out which is used if your 1st choice gouges.

This tab contains the following settings:

Choice — Select the type of move to use before each cutting move.

Linear move — Enter the length to extend the Lead out move after the cutting move finishes. The distance is the length of the linear tangential move between the arc and cutting portion of the toolpath.

A

Lead out

of

Surface normal arc with a

Distance of

0, an

Angle

of

90 and a

Radius of

5.

A

Lead out

of

Surface normal arc with a

Distance of

0, an

Angle

of

90 and a

Radius of

5.

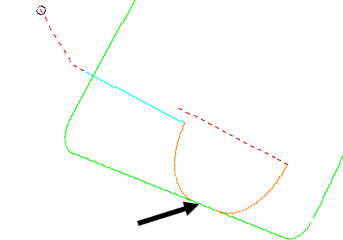

A

Lead out

of

Surface normal arc with a

Distance of 10, an

Angle

of

90 and a

Radius of

5.

A

Lead out

of

Surface normal arc with a

Distance of 10, an

Angle

of

90 and a

Radius of

5.

Angle — Enter the angle of the Lead out move relative to the toolpath segment. For arcs, this is the angle spanned by the arc. For lines, it is the orientation relative to the cutting move.

Radius — Enter the radius of the Lead out arc move.

Length — Enter the length to extend the Lead out move before the cutting move starts.

Ramp options — Click to display the

Lead Out Ramp Options dialog. This determines how the tool ramps out of the stock.

Ramp options — Click to display the

Lead Out Ramp Options dialog. This determines how the tool ramps out of the stock.

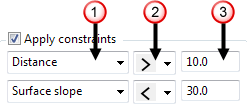

Apply constraints — Select this option to apply constraints to your leads and then select a constraint from the list. Selecting a constraint from the list creates an additional field to apply further constraints. 1st choice and 2nd choice links have a maximum of 2 constraints. If more than one constraint is selected they must all be satisfied for a link to be applied.

To apply constraints:

Select a constraint type from the list:

Select a constraint type from the list:

- Distance — Constrain the link by its distance spanned.

- Surface slope — Constrain the link by the slope angle of the surface at either end of the link.

Select an option from the list to define the constraint limit:

Select an option from the list to define the constraint limit:

-

— The constraint is satisfied if the parameter is less than the specified value.

— The constraint is satisfied if the parameter is less than the specified value.

-

— The constraint is satisfied if the parameter is greater than the specified value.

— The constraint is satisfied if the parameter is greater than the specified value.

Enter the constraint value.

Enter the constraint value.

— Click to copy the

Lead in values to the

Lead out page.

— Click to copy the

Lead in values to the

Lead out page.

— Click to copy the

Lead out values to the

Lead in page.

— Click to copy the

Lead out values to the

Lead in page.

Separate last lead out — Select this option to specify a last lead out move that is different from the previous lead out moves.

Lead out extension — Select this option to add another lead out to existing lead outs. All choices are available except for Pocket centre.

Overlap distance — Enter the distance by which a Lead out can overlap a closed toolpath segment.

Allow start points to be moved — When selected, this option moves the start points on closed toolpath segments to try and find a non-gouging position. When deselected, PowerMill will not move the start points - this means that if you carefully position a start point, you can prevent PowerMill from moving it.

Stagger start points — When selected, this option moves the start points on successive closed toolpath segments so that the start points are spread out on each segment. This allows the tool to maintain forward motion as it moves from one segment to the next.

Add leads at tool axis discontinuities — When selected, inserts leads and links between continuous segments where there is an angular change in tool axis between neighbouring segments. This ensures that any reorientation of the tool axis at a specific point takes place away from the part.

Angular threshold — Enter the minimum angle required before leads and links are inserted. The angle is the change in the tool axis between neighbouring segments.

Gouge check — Select this option for PowerMill to gouge-check all leads and links.

Apply lead outs — Click to update the lead out values to the active toolpath.

Apply — Click to apply the values to the currently active toolpath.

Accept — Click to accept the values on this dialog and closes the dialog.

Cancel — Click to close the dialog without updating the leads and links.