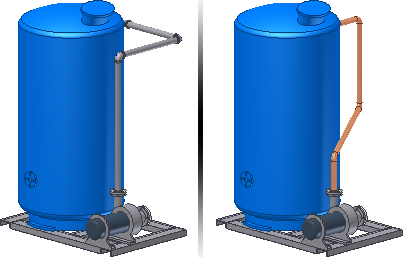

There are two types of rigid routes: rigid piping and bent tubing.

The rigid route styles, Rigid Pipe with Fittings and Tubing with Bends, contain the rules for conduit parts and elbows. A pipe route can comprise pipe segments, couplings, 45-degree and 90-degree elbows, gaskets, gaps for groove welds, and custom bends. A tube route comprises tubing segments and tubing bends. Couplings connect straight segments and elbows or bends connect each directional change point. If a butt weld style is active, and gaps are set to display, straight segments and directional change points have gaps between them. These gaps are for groove welds instead of fittings.

A rigid route can be a series of auto regions and parametric regions:

- To create an auto region, select circular openings and work points as the start and end route points. The system can create any number of segments automatically.

- To create a parametric region, use 3D Orthogonal Route along with the 3D sketch route commands: Point Snap, Rotation Snap, Parallel With Edge, Perpendicular To Face, Bend, and General Dimension.

Auto regions are created where geometric constraints are not important. Parametric regions are created to constrain the route to existing geometry or dimensions. An auto region can be converted to a series of continuous sketched segments at a later time.

| For more information | |

|---|---|

| Help topics | |