Specify the number of points and set the safe distances required for calibrations.

You can also specify the default form tolerance for calibrations when you want to check and record the calibration quality.

Note: Calibration settings are required only when creating inspections for CNC machines or manual CMMs.

- In the Machine tab, click Calibration.

- Click

Calibration settings.

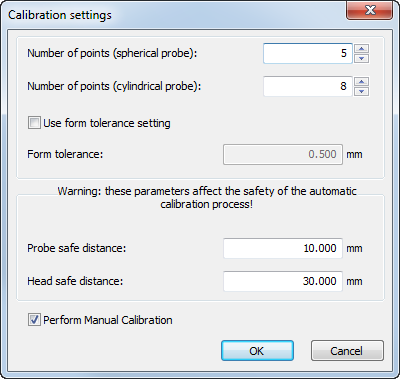

- In the Calibration Settings dialog, in Number of points (spherical probe) box, enter the number of points required to calibrate a spherical probe.

- In Number of points (cylindrical probe) box, enter the number of points required to calibrate a cylindrical probe.

- If you want to check and record calibration quality, select the Use form tolerance setting check box, and enter the Form tolerance for calibration sphere measurements.

- Enter the Probe safe distance and Head safe distance for the measuring device.

- By default, PowerInspect performs calibration probing automatically. If you want to control the positioning of calibration points, select the Perform manual calibration check box.

Note: You must use the manual calibration to calibrate star probes.