Contour Flange Property Panel Reference

Defines a contour flange by adding a sheet metal face defined by an open profile and other parameters to an edge or edge loop on a face.

What's New: 2026

The Contour Flange Property Panel populates with the default settings from the active Sheet Metal Style. You can override these settings on a per flange basis or on a set of flanges. The property panel provides an optimized workflow.

To learn more about property panels see the following topics:

Access

Ribbon: Sheet Metal tab  Create panel

Create panel  Flange

Flange

Contour Flange Property Panel

Specifies the profile, edges, and other parameters from which the contour flange is created.

Flange Name

A default name is provided, but you can double click the flange name to edit and change it.

Advanced Settings

Advanced Settings

The menu at the top-right provides commands relative to the flange workflow.

Active Preset

Displays the named preset in use and provides access to any flange presets you have created. When No Preset displays, property panel fields populate with the last used value.

Add Preset

Add Preset

Creates a custom preset using the current property panel settings. The preset is available for use when creating sheet metal flanges.

Preset Settings

Preset Settings

Provides control over the presets list and the order in which the presets display.

Input Geometry Group

Profiles

Requires an open profile. Automatically selects the open profile sketch if one exists and previews the flange with the default settings.

If no sketch exists or none is visible, the sketch environment activates so you can create the required sketch. If multiple sketches exist, the profile selector is active awaiting a sketch selection.

If multiple solids exist, to which the contour flange could be added, the Solid selector displays.

New Solid

New Solid

Specifies the new flange is to be a separate body.

Body Name

Accept the default naming or specify a name. Displays when New Solid is used.

SM Rule

Select the sheet metal rule to use to create the contour flange. The Sheet Metal Style Default rule is used unless otherwise specified for the new body.

Behavior Group

Width Extents

There are two methods for defining flange width extents.

Along selected edge

Along selected edge

Adds a contour flange along the selected edges. The following controls display for defining the flange.

Edge Sets A collection of one or more edges on which a flange feature is placed. The selected edges do not have to be contiguous.

Edge Loop. Sets the selection priority to edge loops, enabling the selection one edge to get all contiguous edges. The loop edges comprise one Edge Set.

Edge Loop. Sets the selection priority to edge loops, enabling the selection one edge to get all contiguous edges. The loop edges comprise one Edge Set. Add Edge Set. Add an edge set to create a flange with different options. Expand an edge set to access the individual edges in the set and their options.

Add Edge Set. Add an edge set to create a flange with different options. Expand an edge set to access the individual edges in the set and their options. Select Edges

Select EdgesThe selector adds edges to the set. To delete an edge selection set and reset the selector, click the X at the right end of the row, then begin selection.

Edge Set Options

For each Edge Set you can specify the following options:

Edge. Applies parameters to the full length of the selected edge.

Edge. Applies parameters to the full length of the selected edge. Width. Applies parameters to the selected edge, where the flange width is distributed equally from the edge center. Enter the flange Width.

Width. Applies parameters to the selected edge, where the flange width is distributed equally from the edge center. Enter the flange Width. Offset

OffsetEnables a flange to start along the selected edge at a specified distance from a selected perpendicular face or plane.

- Offset From: Select a face that is perpendicular to the flange edge.

- Offset Distance: Specifies the distance from the selected offset face.

Flip Direction: Reverses the offset direction.

Flip Direction: Reverses the offset direction.

Between

BetweenFlange width is defined by the portion of the selected edge lying between the From and To inputs.

- From: The face or plane where the flange begins.

- To: The face or plane where the flange ends.

Offset

OffsetFlange width is defined by offsets from each end of the edge.

- From: The face or plane from which the start offset is measured.

- Offset 1: Specifies the From input offset distance.

- To: The face or plane from which the end offset is measured.

- Offset 2: Specifies the To input offset distance.

From sketch plane

Specifies the contour flange will begin from the profile sketch plane.

From. Uses the sketch plane as the beginning of the contour flange.

Between. enables the selection of a different starting plane. Select a plane or planar face.Note: When using Between, Direction and Distance are reference values defined by the From and To selections.

Between. enables the selection of a different starting plane. Select a plane or planar face.Note: When using Between, Direction and Distance are reference values defined by the From and To selections.Direction. Specifies the direction in which the contour flange is created. The default starting location is the profile sketch plane. Choose from:

Default. Extrudes flange in the positive direction, perpendicular to the sketch plane.

Default. Extrudes flange in the positive direction, perpendicular to the sketch plane. Flipped. Extrudes flange in the negative direction, perpendicular to the sketch plane.

Flipped. Extrudes flange in the negative direction, perpendicular to the sketch plane. Symmetric. Extrudes flange equally in positive and negative directions using Distance A.

Symmetric. Extrudes flange equally in positive and negative directions using Distance A. Asymmetric. Displays controls so two unique distances can be specified.

Asymmetric. Displays controls so two unique distances can be specified.

Distance A specifies the length of the contour flange.

To. Enables the selection a termination feature rather than a distance. Choose from a work feature, point, or planar face.

Bend Edges specifies which edges will receive the contour flange. Select one or more edges.

Position

Specifies which side of the profile the flange is created.

Default. Flange is inside the profile.

Default. Flange is inside the profile. Flipped. Flange is added outside the profile.

Flipped. Flange is added outside the profile. Symmetric. Flange is added with an equidistant offset from the profile.

Symmetric. Flange is added with an equidistant offset from the profile.

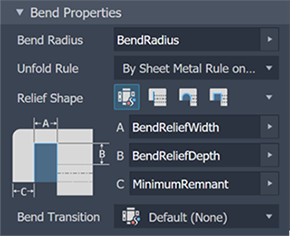

Bend Properties

Bend Radius

Defines the radius of the bend between the flange and the face containing the selected edges. The value defaults to the system parameter named BendRadius, which is defined on the Sheet Metal Styles dialog box. The field accepts numeric entries, formulas, parameters, or measured values.

Unfold Rule

Specifies which methods are used to create a flat pattern from the folded sheet metal part. Sheet Metal Unfold rules are defined in the Style Editor. For more information see To Add, Edit, or Sync a Sheet Metal Unfold Rule.

Relief Shape

Default (by style)

Defined in the Sheet Metal Style. To change the default, modify the style. You can modify the default method by choosing one of the following shapes.

Default (by style)

Defined in the Sheet Metal Style. To change the default, modify the style. You can modify the default method by choosing one of the following shapes.

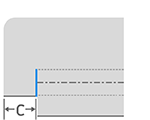

Tear

Tear

An acceptable bend relief resulting from material failure. It is common when tight bends are required and with certain materials. In the illustration, C represents the size of the material remnant left following the creation of the bend with relief. This parameter defines the value.

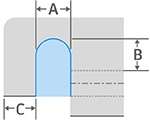

Round

Round

A bend relief shape defined by a cut ending with a semicircle. It is often produced using laser cutting technology. In the following illustration, A indicates the bend relief width (diameter), B indicates the bend relief depth beyond the deformation zone to the tangent point of the diameter, and C represents the size of the material remnant left following the creation of the bend with relief. Each of these parameters define the bend relief defaults.

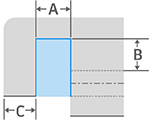

Straight

Straight

A bend relief shape defined by square corners. It is common in manual shop situations and often produced by a saw kerf. In the following illustration, A indicates the bend relief width, B indicates the bend relief depth beyond the deformation zone, and C represents the size of the material remnant left following the creation of the bend with relief. Each of these parameters define the bend relief defaults.

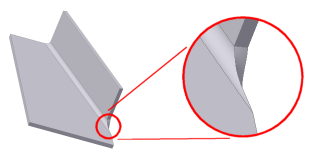

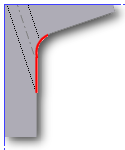

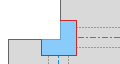

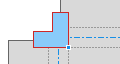

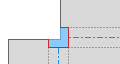

Bend Transition

Defines the condition that shows in the flat pattern of the bend. The folded model shows either the transition type of None (for all transition types except Trim), or the type Trim if that is the selected type. The following images show the transition types for this folded model.

None

None

Depending on the geometry, results in a spline between the edges of the two faces meeting at the selected bend.

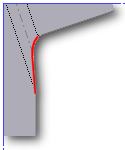

Intersection

Intersection

Results in a straight line from the edge of the bend zone that intersects the edge of the bent feature. In the following illustration, the portion of the flat pattern showing this transition type is illustrated for the folded model shown previously.

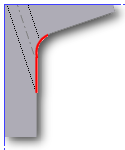

Straight Line

Straight Line

Results in a straight line from the edge of the bend zone that intersects the edge of the bent feature. In the following illustration, the portion of the flat pattern showing this transition type is illustrated for the folded model shown previously.

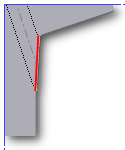

Arc

Arc

Results in a straight line from the edge of the bend zone that intersects the edge of the bent feature. In the following illustration, the portion of the flat pattern showing this transition type is illustrated for the folded model shown previously.

Trim to Bend

Trim to Bend

This type of transition is displayed in the folded model and results in a cut to the bend zone perpendicular to the bent feature. In the following illustration (left), the portion of the flat pattern showing this transition type is illustrated for the folded model shown on the right.

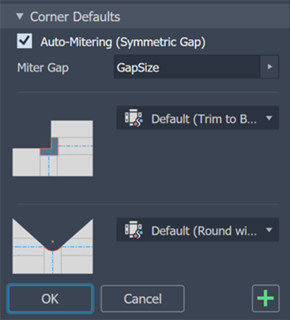

Corner Defaults

Corner defaults are specified in the Sheet Metal Style. Corner defaults are enabled when more than one flange is being created in the same feature. This enables a smooth workflow where the flange requirements are completely defined in one pass. For individually created flanges that require specific corner treatments, use the Corner Seam command.

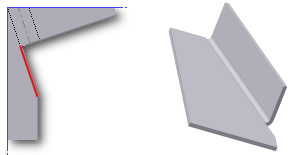

Auto-Mitering

Auto-mitering automatically extends material between adjacent flange edges during creation or edit of at least two flange edges during a single operation where bend angle is greater than 90 degrees. Select the option to have it automatically extend the flanges to create the corner gap.

Miter Gap

Specifies the gap width used when creating mitered corners. The default is GapSize, which is defined in the Sheet Metal Style.

Corner Shape

![]() Default (by style)

Default (by style)

The default is defined in the Sheet Metal Style. To change the default, modify the style.

Round

Intersection A circular cut out centered on the intersection of the bend lines.

Intersection A circular cut out centered on the intersection of the bend lines.

Tangent A circular cut out tangent to the mitered edges.

Tangent A circular cut out tangent to the mitered edges.

Vertex A circular cut out whose circumference intersects the shared face tangency point

Vertex A circular cut out whose circumference intersects the shared face tangency point

Square

Intersection A square cut out centered over the intersection of the bend lines.

Intersection A square cut out centered over the intersection of the bend lines.

Vertex A square cut out whose corner intersects the shared face tangency point.

Vertex A square cut out whose corner intersects the shared face tangency point.

Tear

Tear

Extends the flange edges to their intersection. No relief, which allows material failure (tearing) across the bend zone in the folded model.

Trim to Bend

Trim to Bend

A polygonal cut out bounded by the bending zone lines.

Linear Weld

Linear Weld

A v-shaped cut out defined from the intersection of the inner bend zone lines to the outer bend zone intersection of the line with the flange edges. Minimum relief allows a subsequent weld operation to close the corner.

Arc Weld

Arc Weld

Curves tangent to the flange edges along the outside edge of the bend zone which converge to a flat gap equal to the Miter Gap value. A gap between the flanges that is equidistant along the length of the relief is suitable for subsequent arc welding.

Laser Weld

Laser Weld

Curves tangent to the flange edges along the outside edge of the bend zone which converge to a tangent arc equal to the Miter Gap value. A gap between the flanges that is equidistant along the length of the relief is suitable for subsequent laser welding.

Corner Relief

![]() Default (by style)

Default (by style)

The default is defined in the Sheet Metal Style. To change the default, modify the style.

No Replacement

No Replacement

Does not replace the geometry as modeled in the flat pattern.

Intersection

Intersection

Extends and intersects the flange edges.

Full Round

Full Round

Extends the flange edges to their intersection, and then places a fillet tangent to the bend zone tangency lines. Radii are likely larger than what is produced using the Round with Radius option.

Round with Radius

Round with Radius

Extends the flange edges to their intersection, and then places a tangent fillet of the size specified. Radii are likely smaller than what is produced using the Full Round option.

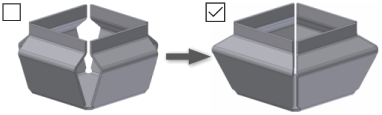

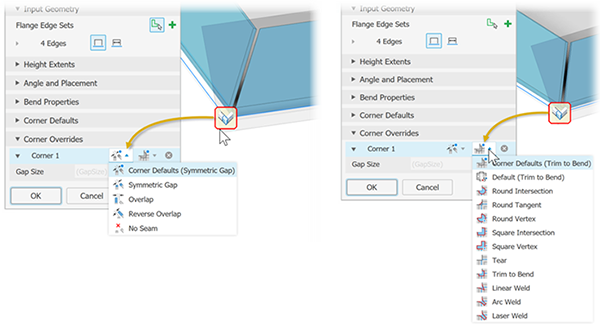

Corner Overrides

Provides overriding relief and shape options for each selected corner when the flange feature is composed of more than one flange.

Corner #

Uniquely identifies corners participating in the selected feature.

Relief Override

Provides corner relief types for the selected corner only. Use the drop down list to select the desired relief condition.

- Corner Defaults: The default is defined in the Sheet Metal Style and displays the related icon. To change the default, modify the style. You can modify the default method by choosing from one of the following conditions.

Symmetric Gap: Extends the flange face of both edges to create an equidistant gap.

Symmetric Gap: Extends the flange face of both edges to create an equidistant gap. Overlap: Extends the flange face of the first selected edge to the outer face of the second selected edge.

Overlap: Extends the flange face of the first selected edge to the outer face of the second selected edge. Reverse Overlap: Extends the flange face of the second selected edge to the outer face of the first selected edge.

Reverse Overlap: Extends the flange face of the second selected edge to the outer face of the first selected edge. No Seam

No Seam

Shape Override

Provides corner shape types for the selected corner only. Select the desired shape from the drop down list. The corner shape list is outlined above.

![]() Gap Size

Gap Size

Sets the gap size for the selected corner. Uses the default size defined in the sheet metal style. Click the icon on the right to override the default.

![]() Relief Size

Relief Size

Sets the relief size for the selected corner. Uses the default size defined in the sheet metal style. Click the icon on the right to override the default.