Activity 2: Face the top

In this activity, we will flatten the top surface of the block in a process called Facing.

Prerequisites

- Activity 1 is complete.

Steps

Start a new facing operation and, from the Tutorial Tools (Metric) library, select the #1 - Ø50 mm (Face mill) tool.

On the Manufacture toolbar, Milling tab, select 2D > Face

.

.On the Tool tab

, click Select. This opens the tool library.

, click Select. This opens the tool library.In the left panel of the Tool Library dialog, select Fusion Library > Tutorial Tools (Metric)

From the list, select #1 - Ø50 mm (Face mill).

Click Select.

Verify the stock Face selection, change the Pass Extension setting to 5 mm, and start the calculation.

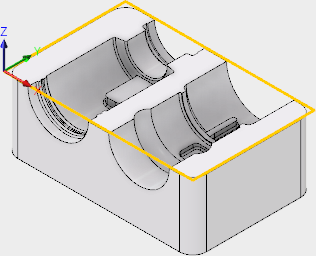

In the Face command palette, click the Geometry tab

. Face assumes the stock area is the same as the machining area. The size of the stock is shown as a yellow outline around the part. There is nothing to specify.

. Face assumes the stock area is the same as the machining area. The size of the stock is shown as a yellow outline around the part. There is nothing to specify.

Click the Passes tab

.

.Increase Pass Extension to 5 mm. The Pass Extension setting specifies the distance to extend the cut beyond the machining boundary shown in yellow.

Click OK to start the calculation.

Activity 2 summary

In this activity you selected a Facing operation, selected a library tool and flattened the top of the part.

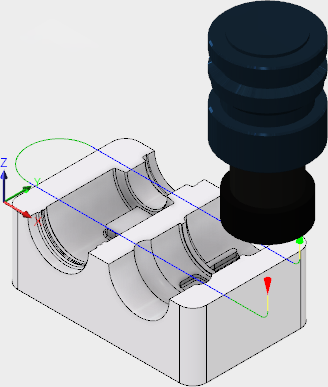

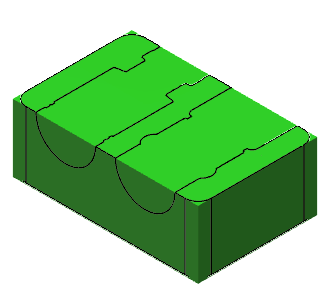

| The calculated toolpath is shown below. | The simulated toolpath is shown below. |

|

|

The toolpath is shown with a red arrow start, yellow rapid move, green lead in/out move, blue cutting moves and a green arrow at the end.