Activity 6: Flat areas

In this activity, we will use the Horizontal strategy to mill all the flat areas on the part,inside the machining boundary.

Prerequisites

- Activity 5 is complete.

Steps

Start a new 3D Horizontal operation and verify that Tool #14 - Ø5 mm R0.5 bullnose, is still the active tool.

- On the Manufacture toolbar, Milling tab, select 3D > Horizontal

.

. - Select the Tool tab

- Be sure tool #14 - Ø5 mm R0.5 bullnose is still the active tool.

- On the Manufacture toolbar, Milling tab, select 3D > Horizontal

Limit the toolpath area to cut below the Top.

- Click the Heights tab

.

. - The Top height drop-down list should be set to Model Top.

- Set the Top height Offset to -1 mm. Since we Face milled the top, this area is already machined. The Offset insures the toolpaths will start below the top face of the part.

- Click the Heights tab

Depth cut settings, Optimal load and Stock to leave.

- Click the Passes tab

.

. - Enable the Multiple Depths.

- Set Maxiumum Stepdown to .4 mm.

- Set Number of Stepdowns to 3 mm.

- Click the Passes tab

Controlling the rapid retract clearance method and the ramp type.

- Click the Linking tab

.

. - Set the Retraction Policy drop-down list to Minimum retraction.

- Set the Ramp Type to Plunge.

- Click OK to start the calculation.

- Click the Linking tab

Activity 6 summary

In this activity you selected a 3D Horizontal operation, restricted the top of the machining area, set multiple passes to remove material on all the flat areas, except the Model Top.

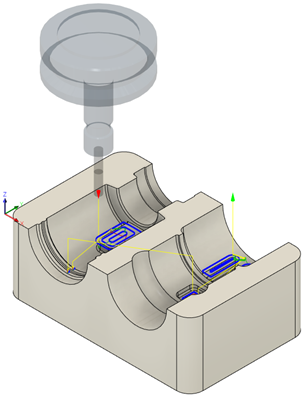

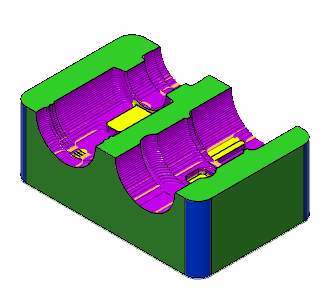

| The calculated toolpath is shown below. | The simulated toolpath is shown below. |

|

|

The toolpath is shown with a red arrow start, yellow rapid move, green lead in/out move, blue cutting moves and a green arrow at the end.