Duplicate components for additive manufacturing

Ensure that you have an additive setup with an additive machine selected.

On the Manufacture workspace toolbar, click Additive > Modify > Duplicate

.

.The Duplicate dialog opens.

Tip: You can preselect components before starting the command; the selection is retained when the dialog opens. Preselecting also allows you to use rectangle select and other selection tools that are not available while the command is active.By default, if the active setup contains only one component, that component is automatically selected. If the setup contains multiple components, on the canvas, select the component you want to copy. To select a component in the browser, navigate to the node of the Manufacturing Model that is used by the current setup, click the chosen component. To select multiple components, click each of them while holding down the Shift key.

Choose a Place Copies option to determine the distribution method. Select:

- At Same Location to place duplicates at the same spot as the originals.

- In Array (True Shape) to place copies at equal distances in a tightly packed arrangement along a selected axis of the machine's coordinate system.

- Along XYZ Axis (Bounding Box) to place copies at equal distances along one, two, or three axes of the machine's coordinate system.

Note: Both In Array and Along XYZ Axis options use the axis directions of the machine used in the current setup.(Optional) Choose a Duplicate Support option to determine how support structures are handled for duplicated components. Select:

- No Support to duplicate components without any support structures.

- Same Support to duplicate components and use the same support operation as the source component.

- New Support to duplicate components and create a separate support operation for each duplicated component.

If you chose the In Array (True Shape) or the At Same Location option, specify the Quantity to determine the count of copies of each component after the Duplicate operation, including the original ones. If you set the Quantity to 1, the operation does not add any component copies to the model.

If you chose the In Array (True Shape) option:

- Specify the Direction along which the copies are distributed.

- (Optional) Select Flip to reverse the direction of distribution along the same axis.

- Specify the Part Spacing to determine the minimal gap between component copies in the array.

- (Optional) Set Voxel Sizing to Custom and adjust the settings to balance the efficiency of the results with the computation time required. With a lower voxel size, the gap between the components in the array gets closer to the value specified in Part Spacing.

If you chose the Along XYZ Axis (Bounding Box) option:

- Set the Quantity of components to place along each axis. The quantity includes the original plus any copies.

- Specify the Part Spacing measured between component bounding boxes.

- (Optional) Select Flip to reverse the direction of distribution of copies along the same axis.

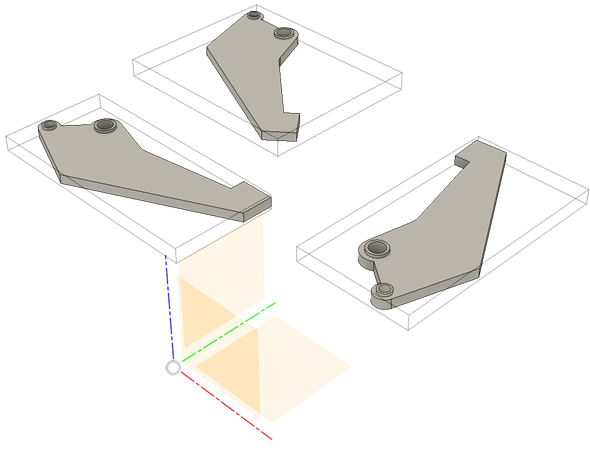

Example of components duplicated along a single axis using the In Array (True Shape) option (A), and the Along XYZ Axis (Bounding Box) option (B), with the same Part Spacing value applied

Tip: The bounding box used used in the Along XYZ Axis method is a virtual box that takes its dimensions from the extents of the component along each axis of the machine's coordinate system. The size and shape of the box depends on the way that the selected component is rotated in relation to the machine platform. To place the component copies tighter together, use the Move tool to rotate the component in a suitable way before opening the Duplicate dialog.

tool to rotate the component in a suitable way before opening the Duplicate dialog.

Click OK.

Copies of the selected components are added to the manufacturing model.