Prepare the design for additive multi-axis deposition

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

Feature Construction additive toolpaths are generated from the surfaces of CAD models. Before you can generate an additive toolpath, you must prepare the features that you want to deposit, and prepare the base surface on which the features are deposited in conformal layers.

Open, or create, a design containing the features and the base surface.

Base surfaces can be planar or non-planar. Non-planar base surfaces can be cylindrical, revolved, or arbitrary surfaces.

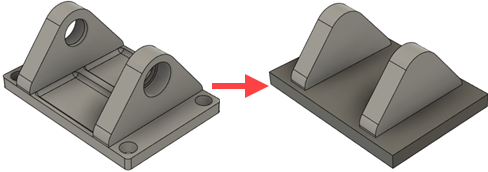

Note: The base surface must be larger than the features that you want to deposit on top.If the design is of the final, machined part, simplify it to remove features, and add additional stock to surfaces, to ensure a successful build.

Tip: Use a manufacturing model to make the simplified design purposely for manufacturing, without affecting the geometry of the original design.

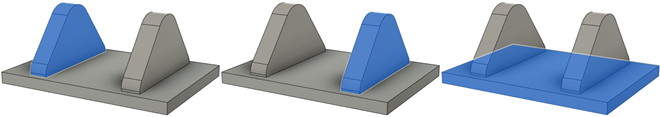

Tip: Use a manufacturing model to make the simplified design purposely for manufacturing, without affecting the geometry of the original design.Ensure that the features to be deposited, and the base surface, are separate bodies and not a single, joined body. If the models are one body, split them up.