Work with materials for nesting

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

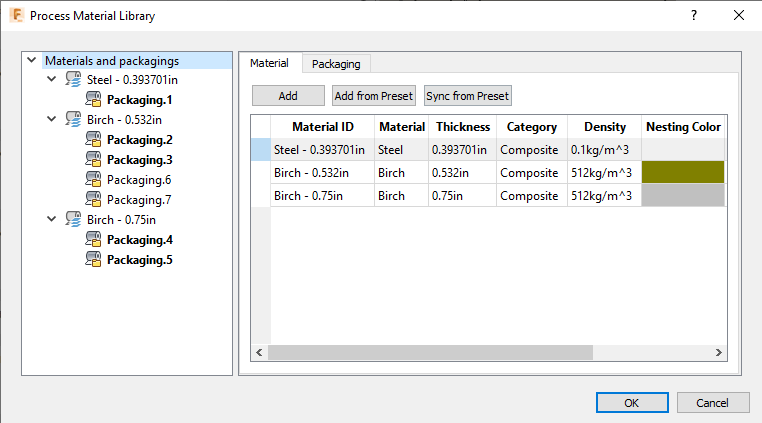

When you create nesting studies, you need to select from a list of available materials that you can use. Create and maintain this list in the Process Material Library dialog. Parameters you set here override those in the Component Sources dialog. You should set up your materials here before using the Component Sources dialog, otherwise materials will be created automatically.

Open the Process Material Library dialog

Click Manufacture > Fabrication > Manage > Process Material Library.

Add Materials

Select Materials and Packagings in the tree on the left side of the Process Material Library dialog.

Add a material in one of the following ways:

Click Add.

The most recently used material is added to the list.

Click Add from Preset and select materials from the dialog that opens.

This shows a list of materials available from presets in the Assets folder.

The first material you add to the Process Material Library will be the default material used for nesting shapes.

In the table, edit details about the material such as ID and category, as well as qualities like thickness and density.

Set Nesting Parameters

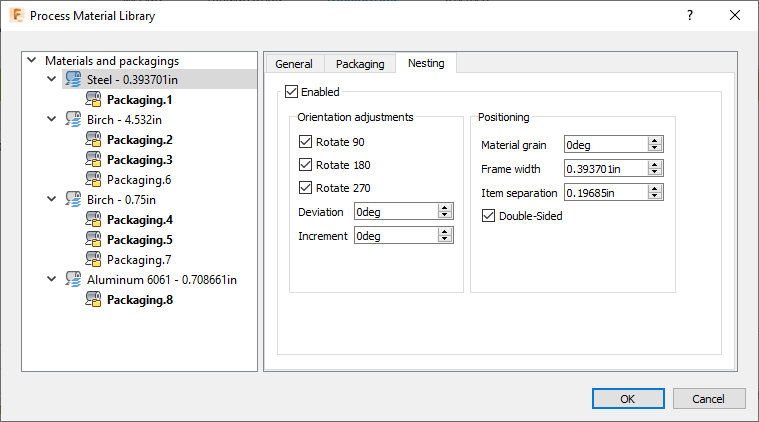

Set default nesting values for materials. These can be changed later when creating a nest.

In the Process Material Library, select a material in the tree and click the Nesting tab.

Select Enabled to include this material in the nest.

If you do not select this, this material will not be available later when adjusting nesting properties.

Make changes as needed to orientation adjustments.

Each material can have a defined set of allowable nesting orientations. From this set of orientations, an optimal orientation is selected for each part as it is nested on the material. (You can also specify allowable orientations when setting up your nest later.)

Rotate: Rotation presets in 90 degree intervals.

Deviation: Allowable deviation from the presets; for example, if you enter 10, a 90-degree orientation is allowed to deviate between 80 and 100.

Increment: Allowable deviation increments. For example, if you enter 2, a 10-degree deviation can occur in increments of 2; that is, 2, 4, 6, 8, and 10.

Note: A large Deviation value combined with a small Increment value can increase calculation times significantly.

Adjust Positioning values.

These are the default positioning settings for nesting.

- Material grain: A base angle from the X-axis that gives the material a grain appearance. To guarantee the same grain on nested shapes, set their orientation and deviation angles to 0, and deselect their Flip, Mirror, and Rotation boxes.

- Frame width: How close shapes are allowed to be placed near the outer perimeter of the nesting area when using this material. This restriction can be refined on each side by adjusting Trim values in packaging.

- Item separation: The allowable distance between items in a nest.

- Double-sided: Select this if the material surface is the same on both its top and bottom. This can be important when considering flip and mirror.

Add Packaging

Any material you intend to use in a nest must have packaging associated with it. If not, any shapes using that material cannot be nested. Add packaging using the Packaging tab.