Turning Groove Finishing strategy

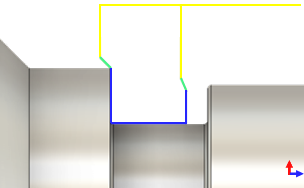

The Turning Groove Finishing strategy removes stock to produce the required shape and surface finish of a groove on the part.

The toolpath can include one or more finishing cuts. Specify the number of cuts in the Stepover box on the Passes tab.

This strategy enables you to machine single grooves. To do so, select the machine single grooves checkbox on the Passes tab. You don't need to create a dedicated Single Groove toolpath.

Turning Modes

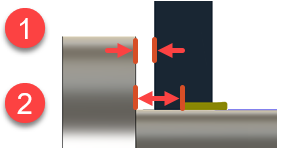

On the Tool tab, you can select one of the following turning modes:

- Outside grooving (1)

- Inside grooving (2)

- Face grooving (3).

Groove suppression

To reduce stress on the tool and the part, on the Geometry tab, you can suppress machining grooves in the toolpath. Depending on selected groove faces, Groove Suppression excludes the groove from machining or machines a shallower groove. Large cutting forces may lead to damaging a tool and poor surface finish. By machining a shallower groove, you reduce cutting forces by distributing them on a larger area.

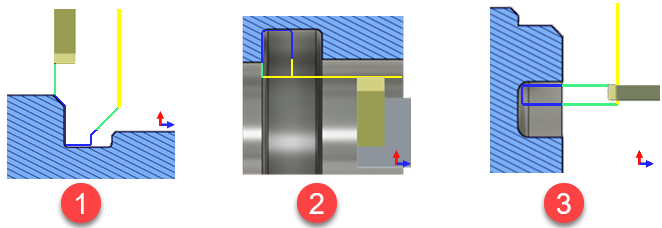

Holder and insert clearance

The strategy enables you to specify clearance between the model and the back of the holder or between the model and the back of the insert of the tool while machining undercuts. The holder or insert keeps the specified distance from the undercut wall. Defining this clearance helps you eliminate collisions and maximize the areas that you can machine in undercuts.