Simulation Extension

Unlock the potential of simulation and generative design technologies to optimize your designs, enhance performance, and improve manufacturing efficiency.

The Fusion Simulation Extension includes the following:

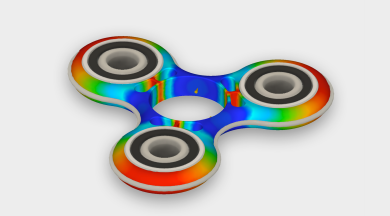

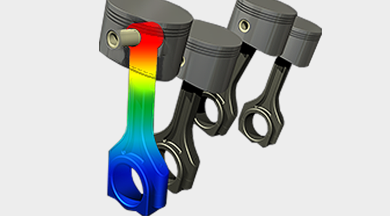

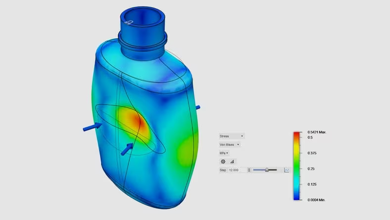

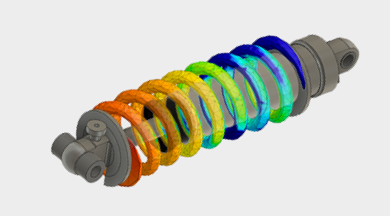

Simulation — Perform a wide range of simulation studies to understand how your design behaves under specific conditions.

Generative Design — Generate and explore multiple design alternatives based on your requirements and objectives.

Learn more about the Fusion Simulation Extension on the Autodesk website.

Note: Extension availability and purchase options depend on which Fusion product you have. The Purchase Manager shows the price for monthly and yearly options in your local currency. Without the Fusion Simulation Extension, you can still run simulation and generative design studies using Flex tokens that are charged per result. Check the Flex Rate Sheet to see the equivalent cost in your local currency.

What's included?

| Simulation Studies | |

|---|---|

|

Modal Frequencies Determine the modal frequencies of the model with, or without, structural loads and boundary conditions. The results include vibration mode shapes, corresponding frequencies and their mass participation factors. |

|

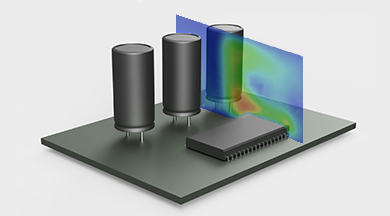

Electronics Cooling Determine whether the temperature of circuit board components will exceed the maximum allowable temperature, given the thermal loads generated by electrical bodies and the air flow in the enclosure. |

|

Thermal, Steady State Determine how the model responds to heat loads and thermal boundary conditions under steady state conditions. The results include temperatures and heat flux. |

|

Thermal Stress Determine temperatures and stress distributions on the model resulting from both thermal and structural loads. The stress-free reference temperature is defined in the study settings. |

|

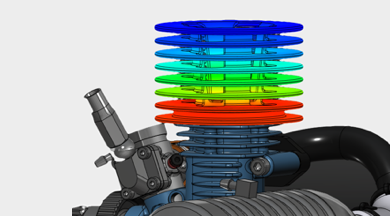

Injection Molding Simulation Determine how well your part will fill, and whether it will have quality issues, based on process settings, material selection, and injection location. View standard results and guided results. |

|

Structural Buckling Determine the buckling modes of the model. The results include buckling modes and their corresponding load multipliers. |

|

Nonlinear Static Stress Determine the static stresses and deformation throughout the model caused by structural loads and boundary conditions while considering nonlinear material properties and large deformations. |

|

Quasistatic Event Simulation Determine the static stresses and deformation in single part or multi-body assemblies where nonlinear material behavior is required. Ideally suited for large motions where the contact conditions can transition from one body to the other. |

|

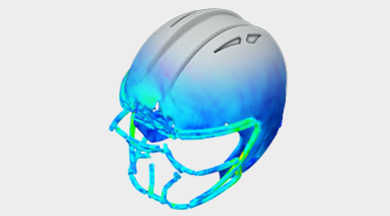

Dynamic Event Simulation Determine how your design responds to rapidly changing time-dependent loads and constraints, including large deformations, initial velocities, contact, and impact. |

|

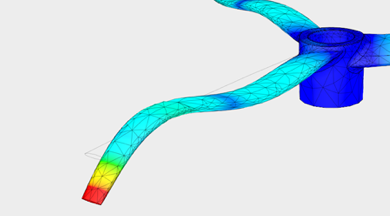

Shape Optimization Optimize parts to make them lightweight and structurally efficient based on the loads and boundary conditions applied to the geometry. |

| Generative Design Studies | |

|

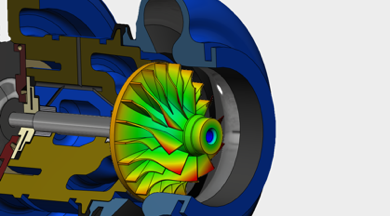

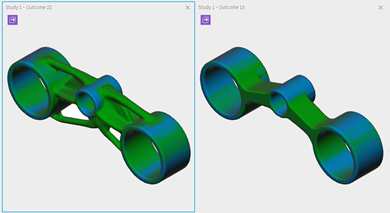

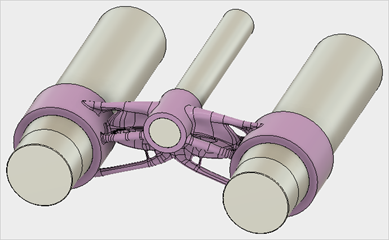

Structural Component - Generate outcomes Generate multiple outcomes based on your geometric, performance, and manufacturing requirements. The outcomes are often better performing and more lightweight than traditional designs. Note: Try a new Fluid Path study available to members of the Fusion Insider Program. |

|

Structural Component - Create 3D designs from outcomes Explore multiple solutions for your design to select the optimal one for your requirements. Create an editable design and mesh design from the outcome and continue to work with it in Fusion. |

Note: The features previously offered by the Generative Design Extension are now available as part of the Fusion Simulation Extension.