Activity 2: Specify manufacturing methods

In this activity, you specify the manufacturing constraints for all methods available in the product.

Prerequisites

- Activity 1 is complete.

Steps

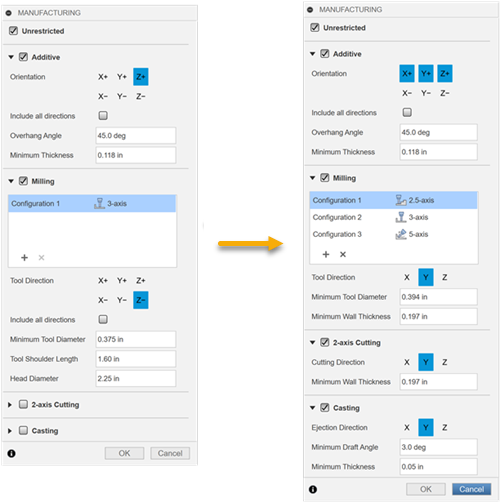

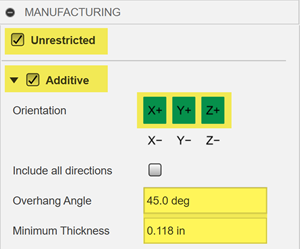

Specify the Unrestricted and Additive manufacturing methods for the generative study by applying the settings shown in the following image.

- On the Define tab, click Design Criteria > Manufacturing

.

. - In the Manufacturing dialog, ensure that the Unrestricted and Additive methods are selected.

- Click X+, Y+, and Z+ buttons to set the 3D printing build direction for additive.

- For the Additive method, ensure that the default values are specified:

- In the Overhang Angle field 45.0 deg.

- In the Minimum Thickness field 0.118 in.

- On the Define tab, click Design Criteria > Manufacturing

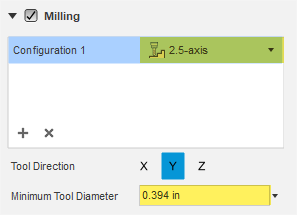

Specify the 2.5-axis milling method to generate outcomes which can be subtractively manufactured using 2.5-axis milling operations by applying the settings shown in the following image.

- In the Manufacturing dialog, ensure that the Milling method is selected.

- From the Configuration 1 drop-down menu, select 2.5-axis.

- Click Y button to set the tool direction for 2.5-axis machining.

Note: It orients the tool in the direction parallel to the Y axis of the triad. We will select this direction for all other methods. - In the Minimum Tool Diameter field, ensure that the default value is specified: 0.394 in.

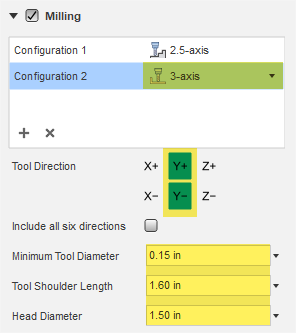

Specify the 3-axis milling method to generate outcomes which can be subtractively manufactured using 3-axis milling operations by applying the settings shown in the following image.

- To add a new milling configuration, in the Manufacturing dialog, click

.

.

Note: By default, the 3-axis milling configuration is added. - Click Y+ and Y- buttons to set the tool direction for 3-axis machining.

Note: It orients the tool in the direction parallel to the Y axis of the triad and pointing to the positive/negative end of the Y axis. - Click Z- button to deselect the default direction.

- In the Minimum Tool Diameter field, enter 0.15 in.

- In the Tool Shoulder Length field, enter 1.60 in.

- In the Head Diameter field, enter 1.50 in.

- To add a new milling configuration, in the Manufacturing dialog, click

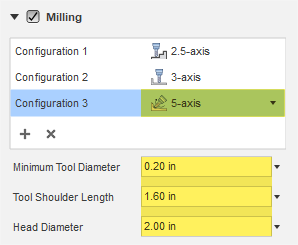

Specify the 5-axis milling method to generate outcomes which can be subtractively manufactured using 5-axis milling operations by applying the settings shown in the following image.

- To add a new milling configuration, click

, and select the 5-axis option from the drop-down menu.

, and select the 5-axis option from the drop-down menu. - In the Minimum Tool Diameter field, enter 0.20 in.

- In the Tool Shoulder Length field, enter 1.60 in.

- In the Head Diameter field, enter 2.00 in.

- To add a new milling configuration, click

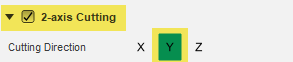

Specify the 2-axis cutting method to generate outcomes which can be manufactured using 2-axis cutting operations by applying the settings shown in the following image.

- In the Manufacturing dialog, ensure that the 2-axis Cutting method is selected.

- Click Y button to set the cutting direction.

Note: It orients the cutting tool in the direction parallel to the Y axis of the triad.

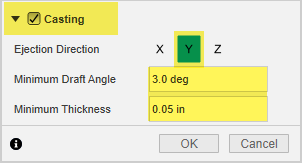

Specify the Casting method to generate outcomes that can be manufactured using the metal casting process by applying the settings shown in the following image.

- In the Manufacturing dialog, ensure that the Casting method is selected.

- Click X and Z buttons to deselect X and Z directions.

- In the Minimum Draft Angle field, enter 3.00 deg.

- In the Minimum Thickness field, enter 0.05 in.

- Click OK.

Tip: To modify the specified manufacturing methods and constraints, mouse over the Manufacturing node in the Browser, and then click .

.

Activity 2 summary

In this activity, you specified the manufacturing constraints for all methods available in the product.