Mesh Dependence

Finite element solutions are notoriously mesh dependent. This is important to keep in mind as you attempt to compare predicted results with experimental results. The mesh size used in your FEA simulation can have a significant impact on your solution.

Impact of Mesh Size on Failure

The ultimate failure of your structure is driven in large part by the peak stresses found in the FEA model. Since those peak stresses can vary with mesh size, you can expect a different ultimate stress depending on the mesh size.

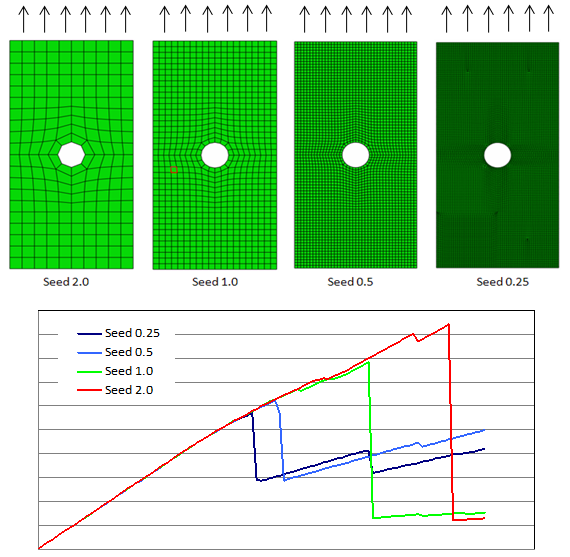

Typically, a larger element size will result in a higher predicted ultimate stress. This occurs because the integration points in larger elements are further away from the stress concentrations. As a result, the element is able to hold more load until failure occurs. In smaller elements, the integration points are closer to stress concentrations. As a result, they can fail earlier which results in a lower predicted ultimate stress. We can see an example of this effect in the image below.

Here we see an open-hole coupon model with four different mesh sizes. When we plot the load-displacement response of each model we can see how the difference in mesh size will influence the predicted ultimate load. Failure will propagate from the stress concentration at the hole more quickly when a small mesh size is used.

Impact of Mesh Size on Ramberg-Osgood Material Parameters

The Ramberg-Osgood material parameters used to define the elastic-plastic material model are also sensitive to the mesh size. If you attempt to manually modify the Ramberg-Osgood material parameters for your nonlinear material, you should consider the mesh size used to calibrate the parameters. A mesh sensitivity study is recommended for this procedure. It is also important to use a mesh size for your models that closely matches the mesh size used during the calibration of the material parameters.