The numbering methods are used to control the part numbers automatically assigned to the elements of the model.

The element numbering of a steel structure differs from one project to another. According to the requirements, the parts are assigned a certain mark to be easily identified. Advance Steel provides clear and distinct numbering methods.

Advance Steel numbering consists of a two stage process:

- First, an identical part detection is performed, where:

- Elements are individually taken, compared geometrically and then grouped into identical part buckets.

- Assemblies are compared and grouped (if they are identical) - component elements are identical from a geometrical point of view and their position along the main element of the assembly is the same.

- After the identical parts and assembly buckets are created, numbering methods are applied to assign the part marks based on a specific set of rules.

The numbering can start from any number, both for single parts and assemblies. If required, post numbering methods can be applied.

During the numbering process, Advance Steel automatically detects the identical parts and assigns them the same mark. The elements are assigned single part marks and assembly part marks.

Identical part detection

The identical part detection is an automated process where Advance Steel checks each element from a purely geometric point of view, and groups them to result in groups of identical parts. When performing this check, several factors are taken into account:

- Object type and generic parameters:

- Objects are always compared with other objects of their type. Therefore, beams will never be compared with plates (even if a flat section and a plate have similar geometric sizes), for example.

- Certain generic sizes are compared first, such as the plate thickness or the beam section type. For example, two geometrically identical steel beams but with different names, will not be considered identical.

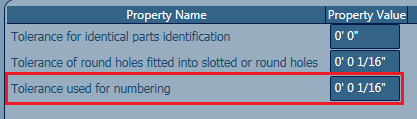

- Tolerance: When the geometry is compared, Advance Steel uses a prest tolerance value to allow very small differences to not interfere with the grouping process. This tolerance works as a length based setting, used not only to compare one of the object sizes, but it can also represent a combination of geometric differences. You can configure the tolerance using the Tolerance used for numbering default value from

(Management Tools)

(Management Tools)  Defaults:

Defaults:

Tip: The tolerance value should be a reasonably small value. A very small tolerance will trigger Advance Steel to find apparently identical assemblies as different (the tolerance can even be set to zero), while a large tolerance (e.g. 1") will group different assemblies into the same part mark.

Tip: The tolerance value should be a reasonably small value. A very small tolerance will trigger Advance Steel to find apparently identical assemblies as different (the tolerance can even be set to zero), while a large tolerance (e.g. 1") will group different assemblies into the same part mark. - Value triggered differences through the object attributes:

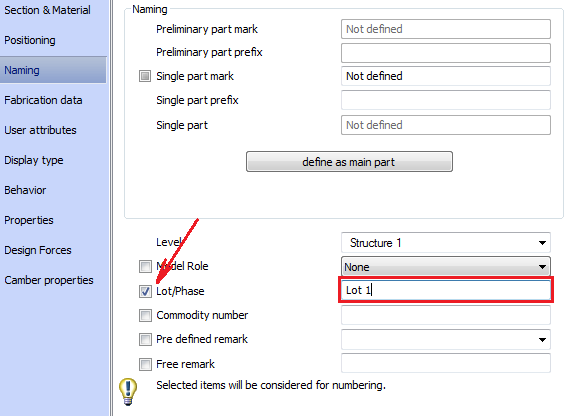

Each Advance Steel element has a small checkbox (by default unchecked) next to its attributes (Model Role, Commodity Number, Lot/Phase, User Attributes, etc.). If you check this box, the respective attribute will be the element that will make the difference in the numbering process, in case two objects are found geometrically identical. This means that, for example, two identical column assemblies can get a different assembly part mark and be numbered differently if the Lot/Phase is different and the checkbox for that attribute is checked: