Wall slip analysis

Wall slip is the term given when fluids violate the classic no-slip boundary conditions of Newtonian fluid mechanics, and do actually slip over solid surfaces when the shear stress exceeds a critical value. It is generally accepted that polymer melts exhibit wall slip.

The mechanism of slip is believed to be the sudden disentanglement of the polymer chains in the bulk from those in the monolayer adsorbed at the wall. When wall slip occurs in injection molding processes, it can affect the throughput and quality of the final product. The wall slip analysis is available only for models with  3D meshes. It is available for all molding processes, and for all analysis sequences that include Fill. Wall slip is turned off in the packing stage, once the cavity is filled, or if a short shot is detected.

3D meshes. It is available for all molding processes, and for all analysis sequences that include Fill. Wall slip is turned off in the packing stage, once the cavity is filled, or if a short shot is detected.

If you have the constants available for your material, the slip velocity model can simulate the effects of temperature and pressure on the slip velocity. If you don't have the materials constants, the linear slip velocity model is used.

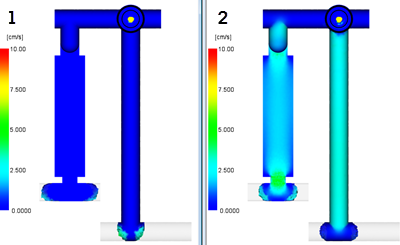

No new results are produced when wall slip is turned on. However, all flow analysis results are affected to various degrees, depending on the magnitude of the slip velocity at the mold wall. An easy way to check the slip velocity at the wall is to plot the Velocity result, with and without wall slip enabled, and to scale the plots appropriately.

Click  (Results tab > Properties panel > Plot Properties) to change the scale, and the plot display so you can see the difference visually.

(Results tab > Properties panel > Plot Properties) to change the scale, and the plot display so you can see the difference visually.

Use  (Results tab > Examine panel > Examine) to find exact values along the part.

(Results tab > Examine panel > Examine) to find exact values along the part.

Comparison of velocity results with and without wall slip

1. Without wall slip, 2. With wall slip

When the velocity profile across the thickness approaches plug flow, the wall slip velocity approaches the same value as the center stream. In this case, you can expect to see a large difference in pressure, filling pattern etc. when you compare results with and without wall slip is enabled. When the velocity profile becomes more curved, this is indicative of little wall slip and you will see little difference when you compare the results with and without wall slip

Limitations

- The slip condition is not applied to beam elements. You must mesh runner and gate systems with 3D meshes to simulate wall slip.

- The constants in the slip velocity model must be characterized, or gathered the data from literature. Autodesk Moldflow Plastics Labs currently do not test for these parameters.

- Analyses may run much slower with wall slip on, as tighter internal solver settings are required. The memory usage, however, is similar.

- Only wall slip at the polymer/wall interface is considered. This implementation does not consider slip between two polymer flow fronts.

- Validation data are limited at this stage.