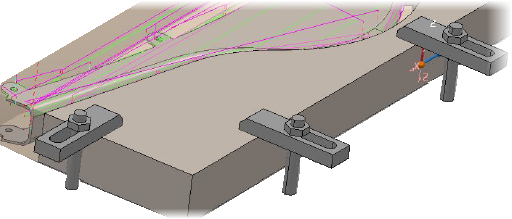

Clamps are PowerMill entities that contain a unique list of model surfaces. They represent the physical apparatus used to secure the stock during a machining operation.

Use clamps to automatically identify the model-surfaces to be avoided, or ignored, when a toolpath in a setup is calculated.

Note: Clamps interact exclusively with setups. For a toolpath to consider clamps during its calculation, the toolpath must be associated with a setup.

When clamps are associated with a setup, the surfaces of the clamps are:

- automatically collision-avoided if a toolpath in the same setup is calculated.

- automatically ignored if a toolpath in a different setup is calculated.

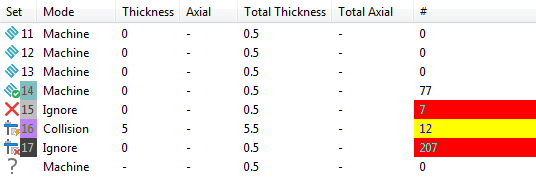

The number of clamp surfaces that are collision-avoided or ignored for each toolpath are displayed on relevant rows of the Component Thickness dialog.

Clamps are a specialized type of level, and the rules for levels apply to clamps when associating surfaces with a clamp:

- Individual surfaces can only be associated with a single clamp. You cannot have the same surface associated with two clamps.

- Clamps cannot have the same name, or share a name with a level or set.