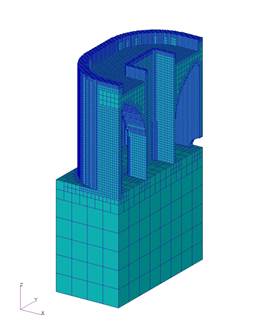

Part-Level Powder-Bed modeling involves activating elements in groups of layers. The feature is triggered by the *PBPA card and requires adaptivity (*ADAP), substrate definition (*DDM!), and Process Parameter File (*PBPF) cards. Each layer group is activated at a fine element scale, as additional layers are deposited on the top, elements below are coarsened. The figures below show the mesh during activation of the 72nd and 91st layer groups.

Mesh after activation of 72nd layer group Mesh after activation of 91st layer group

Part-Level Powder-Bed modeling involves both a thermal and a mechanical analysis. Currently, the powder is removed from the mesh and heat loss into the powder is modeled as convection *CONV. The mechanical analysis uses the temperatures computed from the thermal analysis to compute the mechanical response. The process parameters for part scale modeling are stored in a separate file and read using *PBPF.

In Part-Level Powder-Bed modeling, the input mesh can be automatically generated by importing an STL file using *STLF. When the *STLF option is used, information entered in the *DDM! Card is used to determine the thickness of the buildplate.

Substrate preheating for *PBPA analyses is modeled by using the *INIT card in the thermal analysis only. Continuous controlled heating of the substrate is modeled by the *PBSH and *INIT cards in the thermal analysis only. When substrate preheating or continuous heating is modeled, *INIT in the mechanical analyses should be set to room temperature. The *PBSS card can be used in the mechanical analysis to prevent the substrate from bulging. The *PBIS card can be used to insulate the sides of the substrate during thermal analyses, essentially simulating a build plate withmany different builds. By default the substrate size is small, only extending to the bounds of the .stl box. However, if the user wishes to use a larger substrate the dimensions can be extended using *SBDM or *SBXY. Circular or rectangular fixtures can be added to the substrate using *FIXC and *FIXR, respectively.