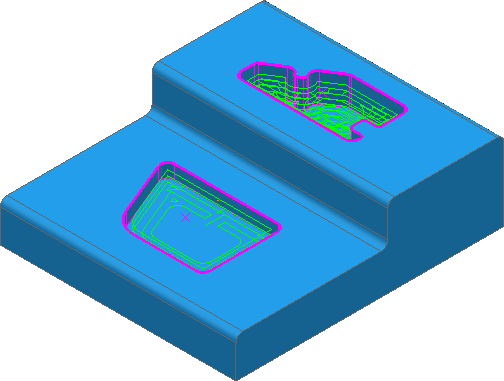

Use the Feature Pocket Rest Area Clearance strategy after a pocket area clearance strategy to rough areas of the pocket features using a small tool, that a large tool could not reach. This strategy enables you to machine multiple pockets at different Z levels.

There are several pages associated with the Feature Pocket Rest Area Clearance strategy:

- Feature pocket rest area clearance — The main page used to specify a feature pocket rest area clearance toolpath.

- Rest — Settings to define rest machining.

- Raster — Settings to define a raster area clearance style. This page is available when you select a Style of Raster on the main page.

- Offset — Settings to define offset area clearance styles. This page is available when you select a Style of Offset model or Offset all on the main page.

- Vortex — Settings to define a Vortex area clearance style. This page is available when you select a Style of Vortex on the main page.

- Step cutting — Settings to define in-line rest roughing. This minimises terracing when creating area clearance toolpaths with a large stepdown. This is available when you select a Stepdown of Automatic.

- Finishing — Settings to perform a Final Stepover and a Final Stepdown which are different from the normal stepover and stepdown.

- Unsafe segment removal — Settings to remove small toolpath segments.

- High speed — Settings to control smoothing options to avoid sharp changes in tool direction when high speed machining. This page is only available for offset styles.

- Order — Settings to control the order of machining.

- Approach — Settings to control how the tool approaches the path.

- Automatic verification — Settings to automatically verify toolpaths on creation.

The remaining pages are common toolpath strategy pages.