Process parameters for a Process Simulation study

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

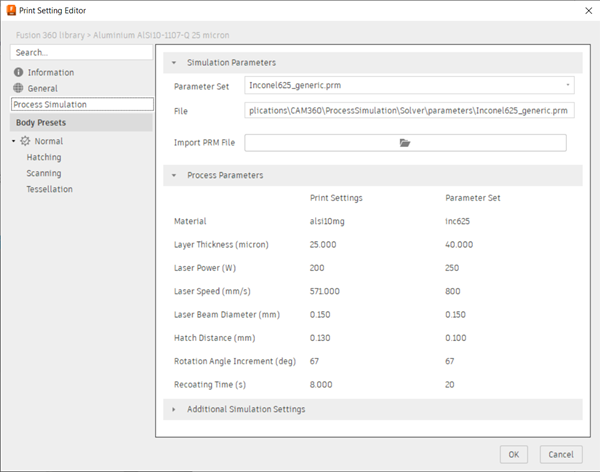

Process parameters, stored in a process parameters (PRM) file, are used during an additive process simulation to simulate certain materials with various settings. Each print setting has a default PRM file associated with it. If you do not want to use the default, you can choose a different PRM file or import one you created outside Fusion.

Example of the process parameters for a print setting.

Comparing print settings to PRM files

Before solving a Process Simulation study, Fusion compares the setup’s print setting with its associated PRM file. The comparison is based on the material and various settings including layer thickness, laser power, laser speed, laser beam diameter, hatch distance, rotation angle increment, and recoating time.

Based on the comparison, a print setting and its PRM file have one of the following statuses:

Direct match: The material and all other settings in the print setting and PRM file match. The process simulation can be solved.

Direct match: The material and all other settings in the print setting and PRM file match. The process simulation can be solved. Close match: The material and other settings in the print setting and PRM file do not match, but the material is supported. The process simulation can be solved, but the results for a close match are not as reliable as that for a direct match.

Close match: The material and other settings in the print setting and PRM file do not match, but the material is supported. The process simulation can be solved, but the results for a close match are not as reliable as that for a direct match. No match: The material in the print setting and PRM file is not supported. The process simulation cannot be solved.

No match: The material in the print setting and PRM file is not supported. The process simulation cannot be solved. Custom PRM: The print setting does not include a material, or you import a PRM file and its material does not match the material in the print setting. The process simulation can be solved.

Custom PRM: The print setting does not include a material, or you import a PRM file and its material does not match the material in the print setting. The process simulation can be solved.