Workflow: Performing a part alignment using probing

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

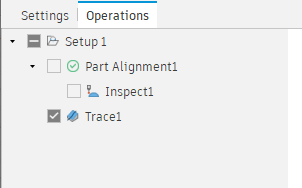

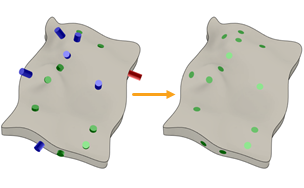

The Part Alignment ![]() feature enables you to use surface inspection results to optimize the setup of complex, free-form parts on a CNC machine. Use it to reduce any alignment imperfections, so that the part can then be machined accurately.

feature enables you to use surface inspection results to optimize the setup of complex, free-form parts on a CNC machine. Use it to reduce any alignment imperfections, so that the part can then be machined accurately.

Steps

Create a milling setup and the manufacturing operations for machining the part.

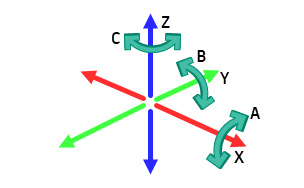

Specify the type of transformation that Fusion uses to calculate the part alignment. This determines the number of axes available to translate and rotate the part so that it can be aligned.

The type of transformation must be supported by the CNC machine and the post processor.

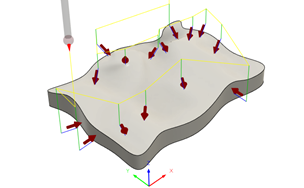

Generate an Inspect Surface operation to specify which points to probe on the part's surface. The surface inspection results will be used to calculate the part alignment.

Post process the Inspect Surface operation to create NC code, and then run the NC code on a CNC machine that has a probe fitted to inspect the part's surface.

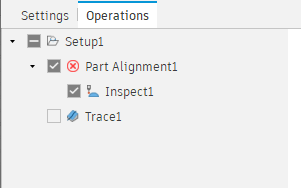

Import the machine-generated inspection results file so that Fusion can calculate the part alignment.

Post process the remaining manufacturing operations using the calculated part alignment, and then run the updated NC code on the CNC machine. The work coordinate system (WCS) on the machine controller is adjusted so that the part can be machined accurately.