Import the results to calculate a part alignment

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

After you have post processed the Inspect Surface operation and run the NC code on the CNC machine, import the machine-generated results file so that Fusion can calculate the part alignment using the specified transformation.

In the Browser, make sure that the Part Alignment node is active.

In the Part Alignment contextual environment, click Get Results > Import Inspection Results

.

.The Import Inspection Results dialog opens.

Next to Results File, click Select to pick a machine-generated results file.

The Results File dialog opens.

Find and select the file you want to import, then click Select.

A progress bar visualizes the import of the results and the calculation of the part alignment.

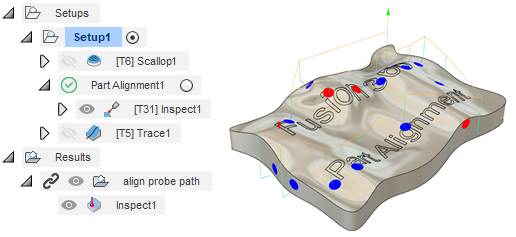

When the import and calculation are complete, colored results are displayed on the model on the canvas. In addition, the results are added as a node in the Browser and linked

to the calculated part alignment. The status icon next to the Part Alignment node changes from uncalculated

to the calculated part alignment. The status icon next to the Part Alignment node changes from uncalculated  to calculated

to calculated  . For example:

. For example: Tip: If you want to reset a part alignment so that it no longer uses the imported inspection results, in the Browser, right-click the Part Alignment node, and then select Reset Part Alignment. The results are no longer linked, and the status icon returns to uncalculated

Tip: If you want to reset a part alignment so that it no longer uses the imported inspection results, in the Browser, right-click the Part Alignment node, and then select Reset Part Alignment. The results are no longer linked, and the status icon returns to uncalculated .

.

By calculating the part alignment, Fusion has worked out how best to adjust the part so that it is in alignment. You can now analyze the inspection results before and after the part alignment has been applied and examine the transformation for the calculated part alignment. After that, post process the remaining operations in the setup using the calculated part alignment and run the updated NC code on the CNC machine. The work coordinate system (WCS) on the machine controller is adjusted so that the part can be machined accurately.