Part alignment using probing

Fusion Manufacturing Extension

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

The Part Alignment ![]() feature helps automate the setting up of complex, free-form parts on a CNC machine. Examples include castings, forgings, and near net shapes.

feature helps automate the setting up of complex, free-form parts on a CNC machine. Examples include castings, forgings, and near net shapes.

Using surface inspection results, Fusion calculates a part alignment to compensate for any misalignment or imprecise fixturing of the part on the CNC machine. It then adjusts the work coordinate system (WCS) on the machine controller so that the parts can be machined accurately.

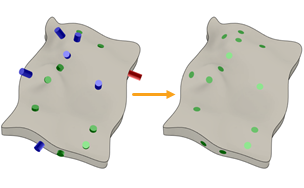

Example of inspection results before (left) and then after (right) a part alignment has been applied.

Creating a part alignment helps:

- Save time by avoiding manual part setting using dial indicators.

- Remove the need for complex fixturing of parts.

- Reduce the scrapping of parts after machining because of inaccurate setup.

- Increase repeatability, part accuracy, and process reliability.

Important: All manufacturing operations require a supporting post processor to send instructions to a CNC machine. Post processors to support new capabilities are constantly under development and will be made available for download from the Post Library when ready. To get help with editing a post processor, visit the HSM Post Processor Forum, or contact a reseller on the Services Marketplace to ask about customizations.