Activity 4: Specify design criteria

In this activity, you specify the optimization objectives and limits that the outcomes should satisfy. Also, you specify the manufacturing constraints for the selected methods.

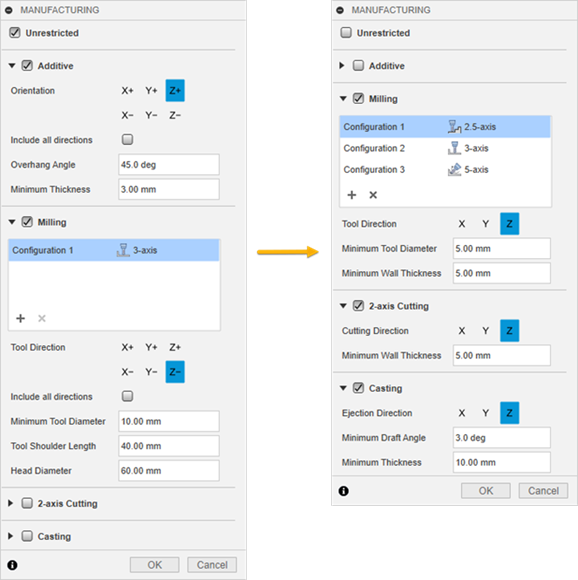

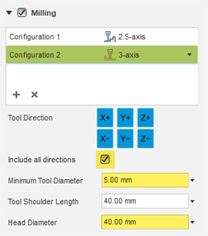

The default manufacturing settings (left) and the manufacturing settings specified in the study (right).

Prerequisites

- Activity 3 is complete.

Steps

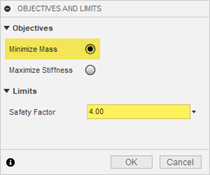

Specify the Minimize Mass objective and Safety Factor 4 limit for the generative study.

- On the Define tab, click Design Criteria > Objectives

.

. - In the Objectives and Limits dialog, ensure that the Minimize Mass button is selected.

- In the Safety Factor input field, enter 4.

- Click OK.

Tip: To modify the specified objectives in the study, mouse over the Objectives node in the Browser, and then click .

.

- On the Define tab, click Design Criteria > Objectives

Exclude the Unrestricted and Additive manufacturing methods from the generative study.

- On the Define tab, click Design Criteria > Manufacturing

.

. - In the Manufacturing dialog, deselect Unrestricted and Additive.

- On the Define tab, click Design Criteria > Manufacturing

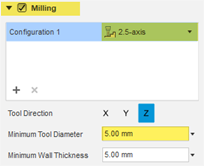

Specify the 2.5-axis milling method to generate outcomes which can be subtractively manufactured using 2.5-axis milling operations by applying the settings shown in the following image.

- In the Manufacturing dialog, ensure that the Milling method is selected.

- From the Configuration 1 drop-down menu, select 2.5-axis.

- In the Minimum Tool Diameter field, enter 5 mm.

Note: It is the diameter of the smallest cutting tool that you plan to use in the 2.5-axis milling operation.

Specify the 3-axis milling method to generate outcomes which can be subtractively manufactured using 3-axis milling operations by applying the settings shown in the following image.

- To add a new milling configuration, click

.

.

Note: By default, the 3-axis milling configuration is added. - To allow for multi-sided machining, select Include all directions.

- In the Minimum Tool Diameter field, enter 5 mm.

Note: It is the diameter of the smallest cutting tool that you plan to use in the 3-axis milling operation. - In the Head Diameter field, enter 40 mm.

Note: It is the diameter of a simplified head that contains the shaft and holder.

- To add a new milling configuration, click

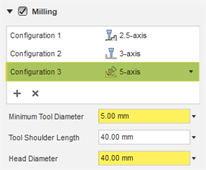

Specify the 5-axis milling method to generate outcomes which can be subtractively manufactured using 5-axis milling operations by applying the settings shown in the following image.

- To add a new milling configuration, click

, and select the 5-axis option from the drop-down menu.

, and select the 5-axis option from the drop-down menu. - In the Minimum Tool Diameter field, enter 5 mm.

Note: It is the diameter of the smallest cutting tool that you plan to use in the 5-axis milling operation. - In the Head Diameter field, enter 40 mm.

Note: It is the diameter of a simplified head that contains the shaft and holder.

- To add a new milling configuration, click

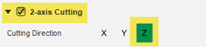

Specify the 2-axis cutting method to generate outcomes which can be manufactured using 2-axis cutting operations by applying the settings shown in the following image.

- In the Manufacturing dialog, select 2-axis Cutting.

- Ensure that the Z button is selected.

Note: It orients the cutting tool in the direction parallel to the Z axis of the triad.

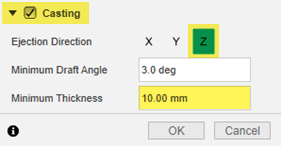

Specify the Casting method to generate outcomes that can be manufactured using the metal casting process by applying the settings shown in the following image.

- In the Manufacturing dialog, select Casting.

- Ensure that only the Z direction is selected.

- In the Minimum Thickness field, enter 10 mm.

- Click OK.

Tip: To modify the specified manufacturing methods and constraints, mouse over the Manufacturing node in the Browser, and then click .

.

Activity 4 summary

In this activity, you specified the optimization objectives and limits that the outcomes should satisfy. You also specified the manufacturing constrains for the generative study.