Activity 4: Specify design criteria and select materials

In this activity, you specify the optimization objectives and limits that the outcomes should satisfy. Also, you specify the manufacturing constraints and select materials for the generative design process.

Prerequisites

- Activity 3 is complete.

Steps

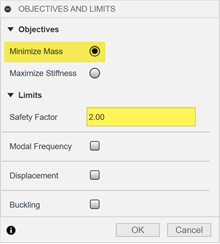

Specify the Minimize Mass objective and Safety Factor 2 limit for the generative study.

- On the Define tab, click Design Criteria > Objectives

.

. - In the Objectives and Limits dialog, ensure that the Minimize Mass button is selected.

- In the Safety Factor input field, enter 2.

- Click OK.

Tip: To modify the specified objectives in the study, mouse over the Objectives node in the Browser, and then click .

.

- On the Define tab, click Design Criteria > Objectives

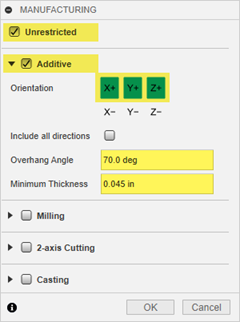

Specify the Unrestricted and Additive manufacturing methods for the generative study, then set the Overhang Angle to 70 deg and the Minimum Thickness to 0.045 in.

- On the Define tab, click Design Criteria > Manufacturing

.

. - In the Manufacturing dialog, ensure that the Unrestricted and Additive methods are selected, and deselect any other manufacturing methods.

Note: The application creates two different types of the outcomes, without and with the additive manufacturing constraints specified below. - Click X+, Y+, and Z+ buttons to set the 3D printing build direction for additive.

- In the Overhang Angle field, enter 70.

- In the Minimum Thickness field, enter 0.045.

- Click OK.

Tip: To modify the specified manufacturing methods and constraints, mouse over the Manufacturing node in the Browser, and then click .

.

- On the Define tab, click Design Criteria > Manufacturing

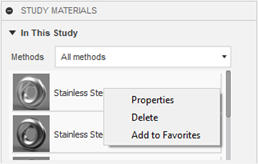

Select Stainless Steel AISI 446, Stainless Steel, 440 C, and Titanium 6Al-4V materials for the generative study.

- On the Define tab, click Materials > Study Materials

.

. - In the Methods section, select Unrestricted from the drop-down menu.

- In the In this Study area, right-click the AlSi10Mg default material, and select Delete from the context menu.

- In the Methods section, select Additive from the drop-down menu.

- Repeat step c to remove the AlSi10Mg default material

- In the Methods section, select All methods from the drop-down menu.

- In the Study Materials dialog, from the Library drop-down list, select the Fusion Material Library.

- Expand the Metal folder, and drag the following materials to the In This Study area:

- Stainless Steel AISI 446

- Stainless Steel, 440 C

- Titanium 6Al-4V

- Click Close.

Tip: To modify the list of materials in the study, mouse over the Study Materials node in the browser, and then click

- On the Document Tab Bar, click Save

.

.

Tip: In the In This Study area, right-click any material to show Properties, Delete, or Add to Favorites. (Favorites is available from the Library drop-down list.)- On the Define tab, click Materials > Study Materials

Activity 4 summary

In this activity, you specified the optimization objectives and limits that the outcomes should satisfy. You also specified the manufacturing constrains and selected materials for the generative study.