Sheet metal flanges

The following tools in the Design workspace, in the Sheet Metal > Create panel, let you create different types of sheet metal flanges based on the profiles you select in Fusion.

You can use the Flange ![]() to create the following sheet metal features:

to create the following sheet metal features:

- Base flange

- Edge flange

- Contour flange

- Hem

- Lofted flange

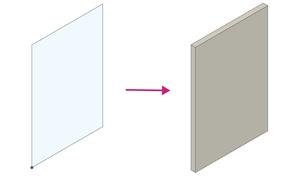

Base Flange

The Base flange creates a flat sheet metal body from a closed sketch profile, that serves as the foundation for additional sheet metal features.

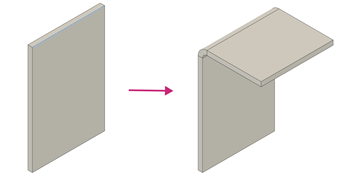

Edge Flange

The Edge flange extends selected sheet metal edges to create flanges at the specified angle and height.

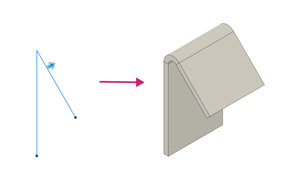

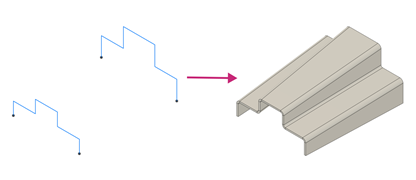

Contour Flange

Contour flange follows the open sketch profile and can include multiple bends in a single operation, honoring bend radii from the sheet metal rule.

You can also join a contour flange to an existing sheet metal edge. The result is a custom-shaped flange that acts like a lip or rim, useful for intricate designs that need strength and form.

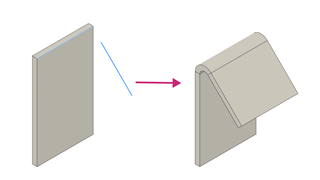

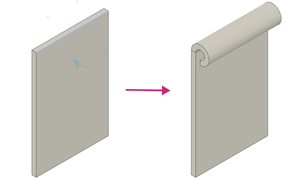

Hem

The Hem tool folds a sheet metal edge back onto itself. Hems help remove sharp edges, add stiffness, and prepare parts for joining.

Hems are commonly used in automotive panels, enclosures, and furniture to enhance safety, strength, and appearance while enabling component joining.

Hem types include:

- Flat

- Creates a fold that rests tightly along the connected flange.

- Creates a fold that rests tightly along the connected flange. - Open

- Creates a fold with a small gap between the edge and connecting flange.

- Creates a fold with a small gap between the edge and connecting flange. - Rolled

- Creates a rounded fold that provides a smooth edge for gripping or fastening.

- Creates a rounded fold that provides a smooth edge for gripping or fastening. - Teardrop

- Creates a rounded fold with an extended flange edge, bent beyond 180 degrees to form a teardrop-like shape.

- Creates a rounded fold with an extended flange edge, bent beyond 180 degrees to form a teardrop-like shape. - Rope

- Creates a rounded fold with an extended flange edge and a small gap between the edge and the connecting flange.

- Creates a rounded fold with an extended flange edge and a small gap between the edge and the connecting flange. - Double

- Creates a double-folded edge by rolling the material twice, resulting in a layered hem with two internal gaps.

- Creates a double-folded edge by rolling the material twice, resulting in a layered hem with two internal gaps.

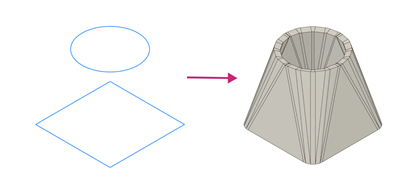

Lofted Flange

The Lofted Flange creates a sheet metal body that connects two different sketch profiles with a transitional shape. You can use two open or two closed sketch profiles.

Closed sketch profiles.

Open sketch profiles.