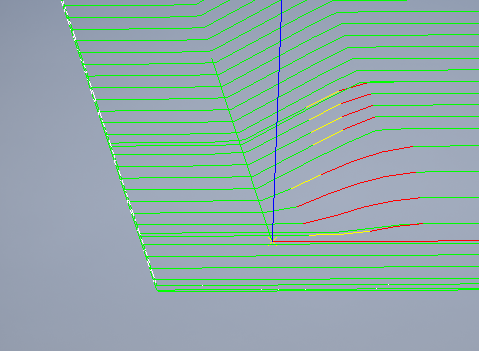

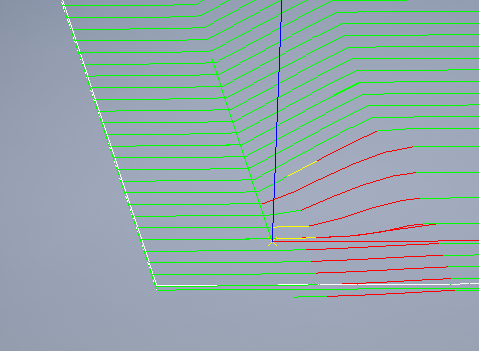

Use an angle analysis to highlight areas of your mesh where the angle of your course approaches or exceeds given values compared to the ply orientation.

- Yellow lines on the ply indicating that the course angle deviation has exceeded the warning value compared to the orientation of the ply.

- Red lines on the ply indicating the course angle deviation has exceeded the allowable limit. (The horizontal red line is the rosette axis.)

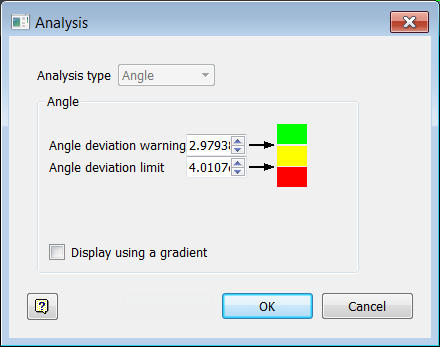

To adjust angle analysis values:

- In the

TruPlan browser, double-click your angle analysis.

The Analysis dialog box opens.

- Optional: Click the color swatches to set highlight colors; from top to bottom, each of these represents the mesh color for:

- Acceptable course angles (green in this example).

- Angles that exceed your warning value (yellow in this example).

- Angles that exceed your limit (red in this example).

- Set angle parameters:

- Angle Deviation Warning: Angle above which the mesh is highlighted with the warning color (yellow). Angles below this are considered to be acceptable.

- Angle Deviation Limit: Angle above which the mesh is highlighted with the limit color (red). Angles above this should be avoided.

- Optional: Select

Display using a gradient.

If you select this, gradients are used depending on the value of the mesh at that specific location. For instance, if the value is greater than the Angle Deviation Warning and less than the Angle Deviation Limit, then the value is displayed as a gradient based on where the actual value is relative to those limits and their colors.

Like with gap analysis, it is up to you to decide if your angles are acceptable for your manufacturing solution. In some cases, you might find that while your angles are acceptable, you might have to compromise them for other strategy properties. For example, a gap analysis might determine that your strategy is resulting in too many overlaps. In this case, you could change the propagation mode of your strategy to Constant Angle Offset to reduce these overlaps, with the result being that there are more angle warnings.

You must compare strategies and analyses in situations like these and decide what will work best for your manufacturing solution.