Use wrinkle analysis to determine if material will be smoothly applied on irregular parts of a surface, such as protrusions or recesses. In these cases, you want to avoid wrinkles, tears and other irregularities as much as possible.

The orange cells in this illustration are examples of wrinkling. Wrinkling is composed of one or both of these characteristics:

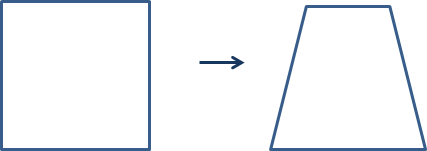

- Shearing: A cell in the ply is angled to one side.

- Spreading: One or more sides of a ply are compressed or stretched.

To adjust wrinkling analysis values:

- In the

TruPlan browser, double-click your wrinkling analysis.

The Analysis dialog box opens.

- Optional: Click the color swatches to set highlight colors; from top to bottom, these colors are used to indicate wrinkling ranges:

- Acceptable shearing (green in this case)

- Too much shearing (yellow in this case)

- Acceptable spreading (green in this case)

- Too much spreading (orange in this case)

- Too much shearing and spreading (red in this case)

- Set wrinkling values.

- Maximum Shearing Angle: This is the angle difference between an original, relaxed, material cell and a material cell sheared across the ply surface. Cells with angles higher than this value will be highlighted with the warning color (yellow).

- Maximum Spreading: This is the calculated percentage change in lengths of the cell borders. Cells whose border length has changed more than this value will be highlighted with the limit color (red).