Using ASM, you can create multi-axis simultaneous toolpaths that allow the continuous variation of the tool axis between moves. PartMaker supports both 4- and 5-axis simultaneous toolpaths:

- 4-axis simultaneous

—

PartMaker machines the part in a 4-axis simultaneous style, with the tool moving in X, Y and Z, while the stock is rotating.

You can create 4-axis simultaneous toolpaths only when using the following machining functions:

- Mill ZY Plane in PartMaker/SwissCAM and PartMaker/Turn-Mill.

- Mill 4-Axis Plane in PartMaker/Mill.

- 5-axis simultaneous

—

PartMaker machines the part in a 5-axis simultaneous style, with the tool moving in X, Y and Z, while the stock is rotating and either:

- the tool head rotating about the B axis for PartMaker/SwissCAM and PartMaker/Turn-Mill, or

- the table rotating for PartMaker/Mill.

You can create 5-axis simultaneous toolpaths only when using the Mill 5-Axis Plane machining function in PartMaker/SwissCAM, PartMaker/Turn-Mill and PartMaker/Mill.

Creating a multi-axis simultaneous toolpath

To create a multi-axis simultaneous toolpath:

- Create a Face window using a machining function that supports multi-axis simultaneous machining:

In PartMaker/SwissCAM and <PRODUCT>/Turn-Mill, you can use the:

- Mill ZY Plane machining function to create 4-axis simultaneous toolpaths.

- Mill 5-Axis Plane machining function to create 5-axis simultaneous toolpaths.

In PartMaker/Mill, you can create:

- Mill 4-Axis Plane machining function to create 4-axis simultaneous toolpaths.

- Mill 5-Axis Plane machining function to create 5-axis simultaneous toolpaths.

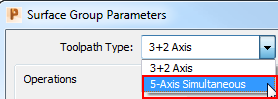

- Click

to create a surface group and display the

Surface Group Parameters dialog, and then use the

Toolpath Type field to select the type of toolpath you want to create.

to create a surface group and display the

Surface Group Parameters dialog, and then use the

Toolpath Type field to select the type of toolpath you want to create.

- Select 4-Axis Simultaneous to create a 4-axis simultaneous toolpath:

- Select 5-Axis Simultaneous to create a 5-axis simultaneous toolpath:

- Select 4-Axis Simultaneous to create a 4-axis simultaneous toolpath:

- In the

Surface Group Parameters dialog, select the type of operations and machining strategies for the toolpath. The following operations and strategies are available for both 4- and 5-axis simultaneous machining unless otherwise stated:

Finishing operation strategies:

- Raster finishing

- 3D Offset finishing

- Constant Z finishing (5-axis simultaneous toolpaths only)

- Swarf finishing

- Wireframe swarf finishing (5-axis simultaneous toolpaths only)

- Spine finishing

Projection strategies:

- Pattern finishing

- Complete the other settings you require for the surface group, such as other settings in the Surface Group Parameters dialog and settings on the Strategy dialogs (available by clicking the Options button).

- When you have finished, click Close to save your settings and close the Surface Group Parameters dialog.