The

Op List

tab in the

Results window shows all of the operations needed to machine the features. A yellow warning

sign next to an operation indicates a potential problem with that operation. In this case, if you see any warnings ignore them.

sign next to an operation indicates a potential problem with that operation. In this case, if you see any warnings ignore them.

You can control the automatic ordering of operations by using either rules or operation templates. The turning tutorial looks at operation templates.

- Select the Automatic Ordering option on the Op List tab. This ensures the automatic ordering rules are applied to the operations.

- Change the automatic ordering to group together the operations which use the same tool.

- Click the

Ordering options

button.

button.

- In the Automatic Ordering Options dialog, select Minimize tool changes, deselect everything else, and click OK.

- Click the

Ordering options

- Simulate the part.

- Click Home tab > Simulation panel > Sim mode > 3D to change the simulation type.

- Click

Play

on the Simulation toolbar to start the simulation.

on the Simulation toolbar to start the simulation.

Notice that the simulation first performs all the spot-drills, then the drills, and then the rough and finish milling for the pockets.

- Click

Stop

to end the simulation.

to end the simulation.

- Change the automatic ordering to move the finish operations to the end of the list.

- Click the

Ordering options

button.

button.

- In the

Automatic Ordering Options dialog, select

Do finish cuts last, deselect everything else, and click

OK.

This changes the order of operations in the Operation List.

- Click

Play

on the Simulation toolbar to start the simulation.

on the Simulation toolbar to start the simulation.

The finish cuts for the two pockets are now cut last.

- Click

Stop

to end the simulation.

to end the simulation.

- Click the

Ordering options

- Simulate the part.

- Click

Play

on the Simulation toolbar to start the simulation.

on the Simulation toolbar to start the simulation.

The finish cuts for the two pockets are now cut last.

- Click

Stop

to end the simulation.

to end the simulation.

- Click

Play

- Change the automatic ordering to match the order of the features in the

Part View panel.

- Click the

Ordering Options

button.

button.

- Deselect everything, and click OK.

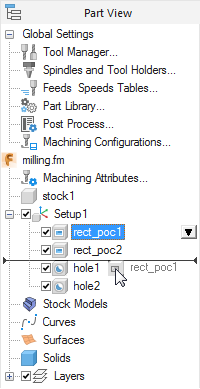

- Open the Part View panel by clicking Part View on the left of the Graphics window. The tree view contains all the setups and features you have created.

- Click the

rect_pock2 item in the

Setup1 node, and drag it up above

hole2.

- Click

Play

on the Simulation toolbar.

on the Simulation toolbar.

The second pocket is cut as the second feature.

- Click

Stop

to end the simulation.

to end the simulation.

- Click the

Ordering Options

- Simulate the part.

- Click

Play

on the Simulation toolbar.

on the Simulation toolbar.

The second pocket is cut as the second feature.

- Click

Stop

to end the simulation.

to end the simulation.

- Click

Play