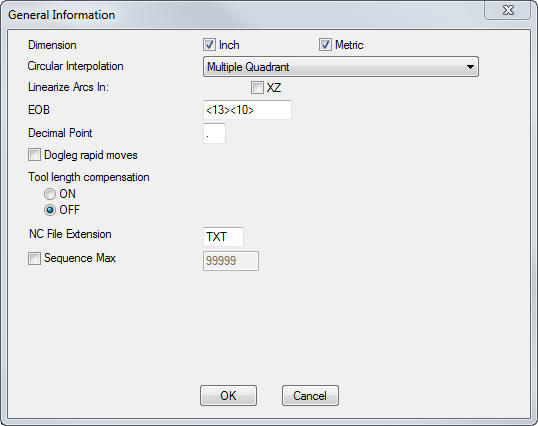

The General Information dialog enables you to specify the output program format.

You can specify the following parameters:

Dimension — Selects whether the post is in Inch or Metric units, or both. We recommend posts that support both units.

Circular Interpolation — Select the programming format on the CNC for which the post processor is being built. You can choose Multi-Quadrant, Single Quadrant, or Not Supported option, as appropriate. For example, if the Numerical Control cannot drive an arc across a quadrant line (plus or minus X and Y axes), then select Single Quadrant circular interpolation. When circular interpolation is turned off in post, then wrap tolerance is used to control fineness of toolpath.

Linearize Arcs In — Select which plane(s) on the machine allow linearization.

Decimal point — Enter the decimal point character, for example: (US and UK) or (Europe).

Dogleg rapid moves — This setting only affects the simulation. When the option is selected, both simulated axes move at the maximum rate during a rapid move from point A to point B until one of the moves is completed. The machine then proceeds to B with the other axis continuing in a straight line.

When the option is unselected, the simulation shows all rapid moves from point A to point B as straight lines

Tool length compensation — This allows for the compensation of tool length by subtracting the tool's X and Z length from the coordinate data at post processing time.

Using Tool Ln Comp allows the user to shift or compensate for different tool lengths without presetting the origin for each tool. For Japanese machines such as FANUC, this selection should be turned Off. If the output is to be incremental, Tool Ln Comp must be turned On.

NC File Extension — The default file extension for your CNC programs. For example if it is set to txt, and your part is called bracket, the G-code file is called bracket.txt.

Sequence Max — Select this option to enter a maximum value for sequence numbers, after which sequence numbers restart. If Sequence Max is deselected, no limit is set.