Improved cooling simulation

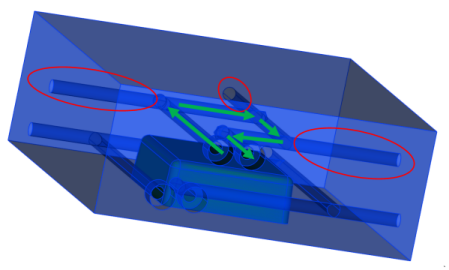

Stagnant coolant in a mold heats up and impacts on the heat of the system.

Stagnant areas are a consequence of the mold construction process, where construction holes are plugged to direct coolant in the appropriate direction.

Previously, you trimmed the stagnant areas, applied a coolant inlet and ran the analysis.

With this release, you can leave the stagnant areas, but you must apply both a coolant inlet and a coolant outlet (  Boundary Conditions tab > Cooling panel > Coolant Inlets/Outlets).

It is important that you assign an outlet so that the software can determine the direction of coolant flow and the stagnant areas.

Boundary Conditions tab > Cooling panel > Coolant Inlets/Outlets).

It is important that you assign an outlet so that the software can determine the direction of coolant flow and the stagnant areas.

The impact of the stagnant areas on the heat of the system is included in the analysis.