Quickstart Warp analysis: Tutorial review

In previous task, you reviewed the results of a Cool+Fill+Pack+Warp analysis.

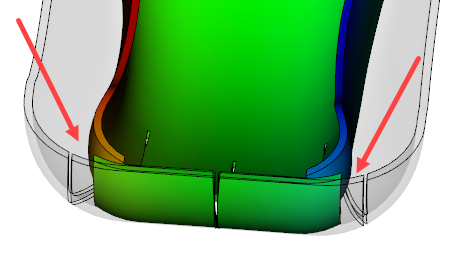

There were two contributing factors to the warpage, of the in the slits area for the part; differential cooling and corner effects.

Differential cooling related warpage is caused by the mold surface temperature on one side of a plastic surface to the other. In this case, it is easy to think of the cavity side and core side. The core side at maximum, is nearly 20C hotter than the cavity side. The hotter side on the core makes the sides of the mouse move in, causing the large warpage in the slits area, and the center of the long sides.

Corner effects related warpage is caused by a difference in shrinkage in plane to through the thickness. The difference in shrinkage effects the warpage at corners, hence the name corner effects. The mouse does not have sharp corners, but there are corners none the less.

To reduce the warpage, both differential cooling and corner effects should be addressed.

Be Adventurous

See if you can reduce the warpage by addressing differential shrinkage and corner effects. Consider doing the following:

- Save the study with a new name

- Reduce the coolant temperature of the core cooling circuits by 20C

- Change the pack/holding profile to, 0s - 100%, 6s - 100%, 3s - 0%

- Run another analysis

- Review the deflection results