6.4 Simple Grillage

Subjects Covered

- Refined Analysis

- 2D

- Transition Curve Design Lines

- Construction Lines

- Meshing

- Slab Properties

- Support Conditions

- Data Reports

Outline

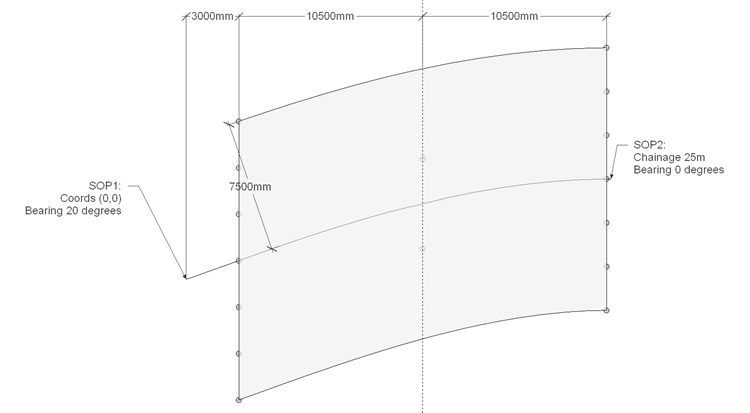

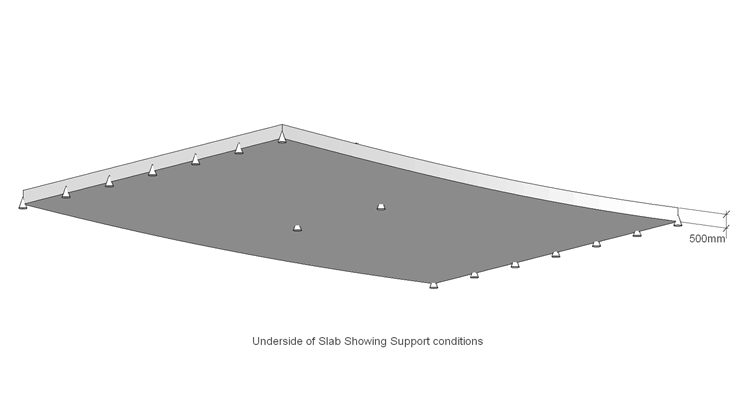

A flat slab, 500mm thick, is shown below with setting out dimensions. It is to be modelled as a grillage in Autodesk Structural Bridge Design and the data file saved for analysis in Section 7.

It is supported on 7 discrete bearings at each end of the slab and 2 bearings at midspan. The two midspan bearings are parallel to the bearings at the slab ends and are located on a line parallel to the deck centre line but running through the bearings either side of the centre. All supports are restrained in the vertical direction but the centre bearing at the left end is also restrained in both horizontal directions while that at the right end additionally restrained in the transverse direction.

The mesh will have seven longitudinal members parallel to the centre line. As there is a reasonable skew at the left end of the slab, the transverse members will be orthogonal to the centre line to give the most accurate results. To ease the positioning of the central supports and to provide some form of mesh refinement at these locations, the mesh will be generated in two. The left mesh will have 5 transverse members (in the non skewed region) and the right mesh 7 transverse members.

The single Carriageway is 12m wide with a 1.5m verge on either side and is centred on the deck.

The concrete is grade C40/50 so it will have an elastic modulus of 35.2205GPa and a shear modulus of 14.675GPa. In defining the section properties of the grillage members it is important that the torsional stiffness of the slab is split evenly between the longitudinal and transverse members.

Procedure

Start the program and select the New drop down button item Create From Template and pick the “EU Project” template.

Setup

- Using the File | Titles menu option set the Project title to “Simple Curved Grillage Model” with a sub title of “Example 6.4”.

- Also set the Job Number: to “6.4” and close the form with ✓ OK.

- Click on Add Model | Refined Model in the toolbar at the top of the Structure Definition pane.

Design Lines

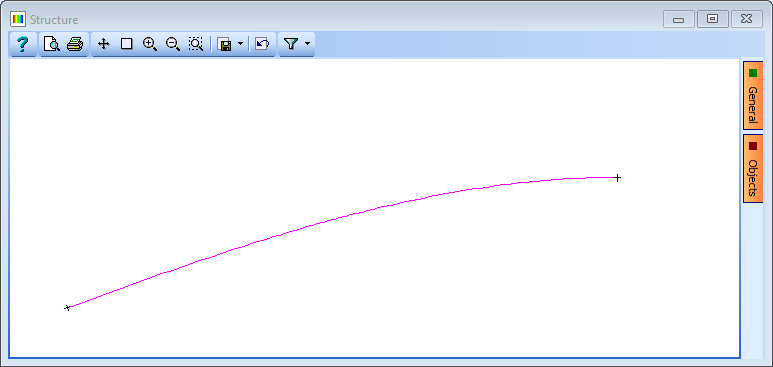

With the "Refined Model" node selected in the Structure Definition navigation window, click on the button to select Design Line from the selection list. This will create an entry in the navigation tree and open the Define Design Line form.

Note: A design line needs to be created to represent the transition curve of the deck centre line.Click on the small + button at the bottom of this form to add a segment and open the Define Line Segment wizard.

Set the segment type to Transition Curve and click on the Next > button.

Set the method to start point, start angle, end angle and length (clothoid) then click on the Next > button.

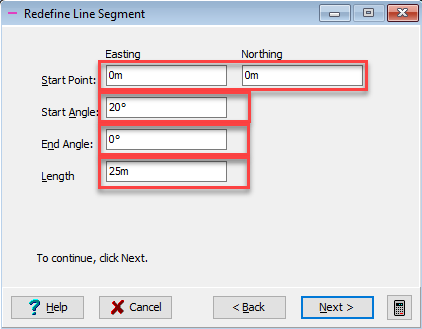

The Start Point: coordinates should be (0, 0), the Start Angle: “20°”, End Angle: “0°”, and chainage Length: “25m”. Click Next >.

Close the wizard with the ✓ OK button to enter the segment into the Design line table.

Before closing the Define Design Line form with the ✓ OK button, change the Name: to “Deck CL”.

Carriageway

A carriageway is added by clicking the

button at the top of the navigation window and selecting Carriageway.

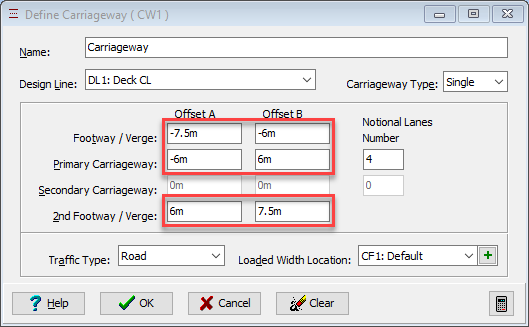

button at the top of the navigation window and selecting Carriageway.In the Define Carriageway form, set the Design Line to “Deck CL” and then enter the relevant offsets as shown below.

Set the Traffic Type to “Road”. It should be noted that a negative offset to a design line is on the left hand side as you walk along the design line.

Click on the “Fit View” icon

in the graphics toolbar to view the carriageway fully.

in the graphics toolbar to view the carriageway fully.

Close the Define Carriageway form with the ✓ OK button.

Construction Lines

To define the corners of the slab it is necessary to create some vertical construction lines that will intersect the edges of the verge. Construction lines are created within a sub model so a new sub model needs to be created first.Use the

button in the navigation window to add a 2D Sub Model (GCS, Z= 0) object. This sub model is automatically in the XY plane.

button in the navigation window to add a 2D Sub Model (GCS, Z= 0) object. This sub model is automatically in the XY plane.Right click on the new sub model in the navigation window and select Add | Construction Lines.

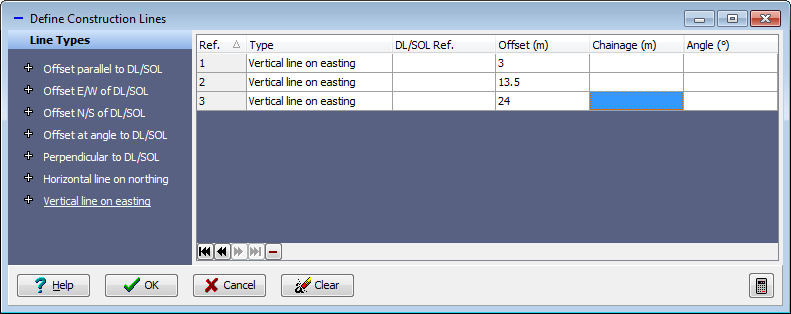

In the Define Construction Line form, click on the + Vertical line on easting option and enter an Offset of “3” (click on the enter key before proceeding or the data will be lost). The blue line can be seen graphically.

Repeat this with offsets of 13.5 and 24 so that there are three construction lines in the table.

Close the Define Construction Line form with the ✓ OK button.

At this point save the data file as “My EU Example 6_4 Curved Slab Layout.sst” using the main menu File | Save as

Grillage mesh

We can now define the two meshes. First select and then Right mouse click on the 2D sub Model in the navigation window and select +Add | Mesh. This will display the Define Mesh form.

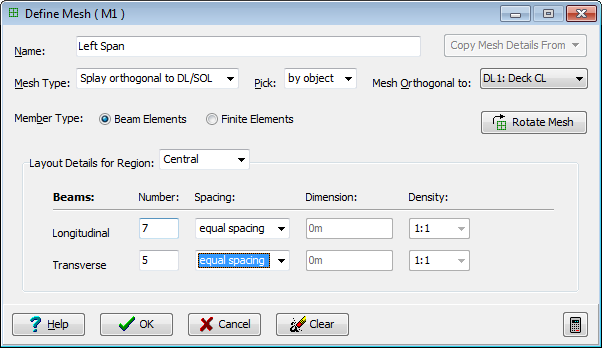

Set Name: to be “Left Span”, Mesh Type: to be “Splay orthogonal to DL/SOL”, Pick: “by object” and Member Type: to “Beam Elements."

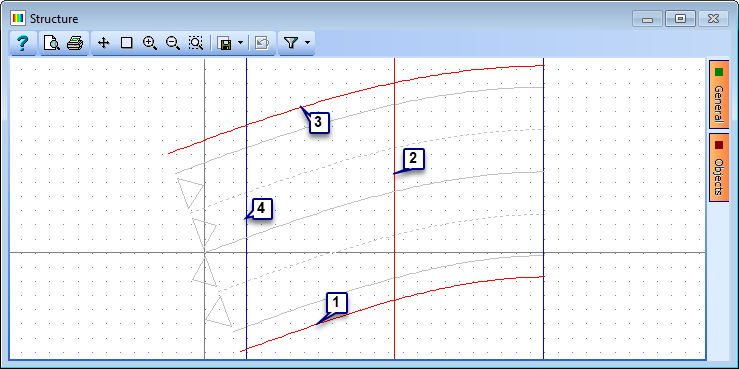

The boundary of the mesh is then picked graphically by selecting the four boundary edges of this span. They must be picked so that consecutive lines intersect (in order) and the first line defines the general longitudinal direction, the second defines which is the positive direction (as can be shown by the arrow in the graphics).

Start on the bottom verge line, then the middle construction line, next the top verge line and lastly the leftmost construction line.

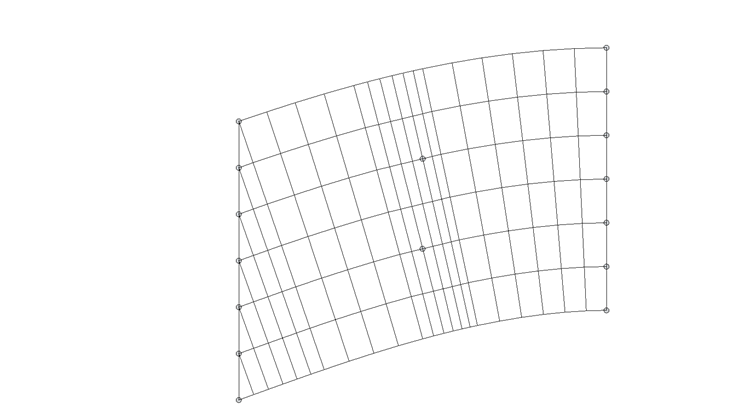

Set the no. of Longitudinal members to “7” and Transverse to “5” and note the change in the graphics. The first mesh is now complete so close the form with the ✓ OK button.

Repeat steps 23 to 26 but set the name to “Right Span” and pick the boundary of the right span. The other parameters can be copied from the first mesh by clicking on the “Copy Mesh Details From” button although the number of transverse members needs adjusting to “7”.

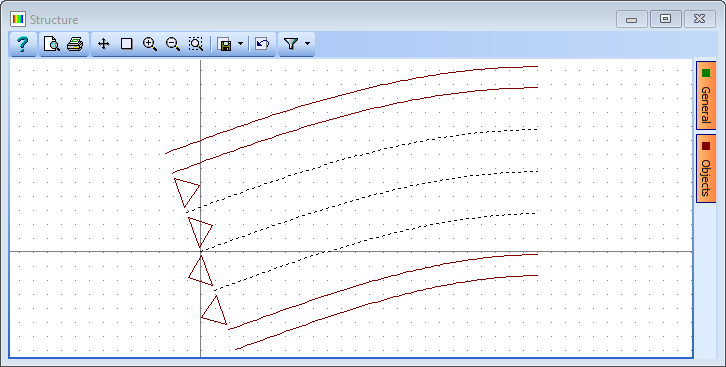

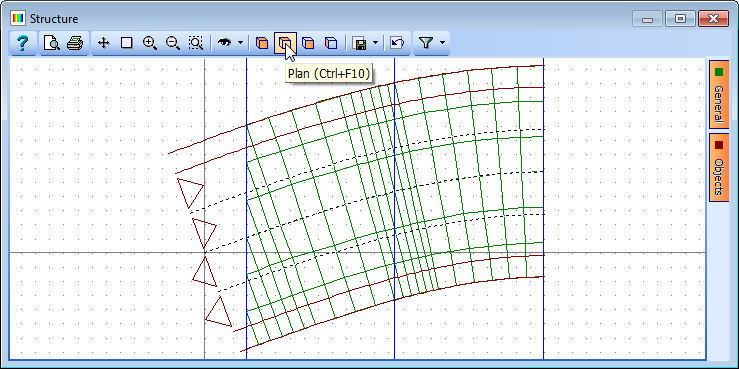

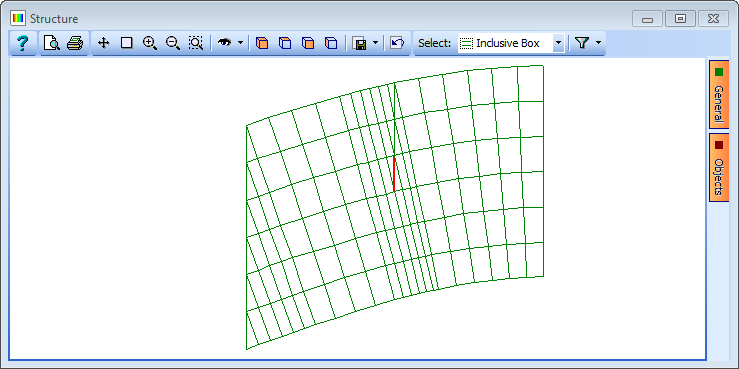

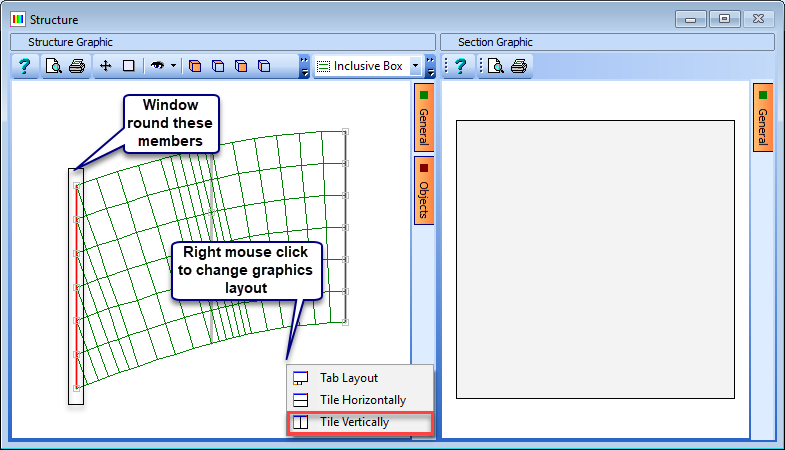

Click on the Refined Model node in the navigation window and in the graphics screen change the viewing direction to plan view by using the

icon. The mesh should now look like the picture below:

icon. The mesh should now look like the picture below:

As well as the main longitudinal and transverse members, the mesh generation has created rows of members along each of the span end lines, which could represent diaphragm members in many forms of deck. This row of members along the middle “span end line” is not required so we will remove them.

This is done by first clicking on the Members Details item in the navigation window, which opens the Member Details data form.

We can remove each unwanted member by clicking on it in the graphics window and then clicking the small - button at the bottom of the table.

Close the Member Details form with the ✓ OK button.

Span End Lines

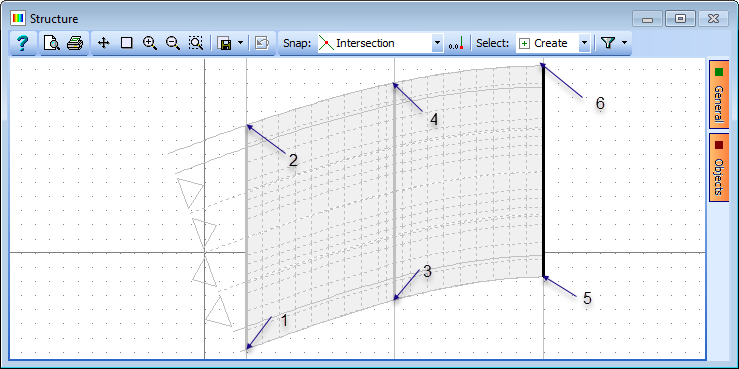

Before positioning supports we will define the span ends by drawing the span end lines. This is done by right clicking on Structure in the navigation window and selecting +Add | Span End Lines.

The coordinates of each end of the lines could be entered manually into the table but it is easier to set the Snap: mode (Graphics toolbar) to Intersection and pick the joints of the mesh coinciding with the span ends. The sequence of clicks to give three lines would be as follows:

Close the Define Span End Lines data form with the ✓ OK button.

Supports

Click the

button at the top of the navigation window and select Supported Nodes to open the Define Supported nodes form.

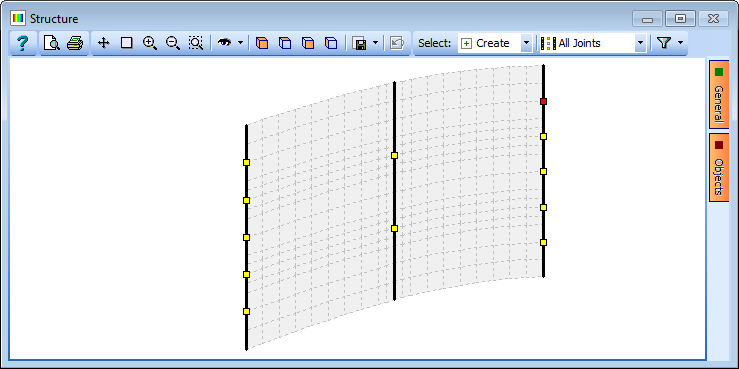

button at the top of the navigation window and select Supported Nodes to open the Define Supported nodes form.Each node along the two outer span end lines and two of the nodes along the middle span end line needs supporting. This is most easily achieved by supporting all nodes under the span end lines and then removing the ones not required.

In the graphics window box round the whole structure in the normal way which will place a support on each node under the span end lines (this is because one of the Welect: options in the graphics toolbar is set to Along Span End Lines).

Now change the Select: option in the graphics toolbar from “Create” to “Remove” and then click on the unwanted nodes to leave the following:

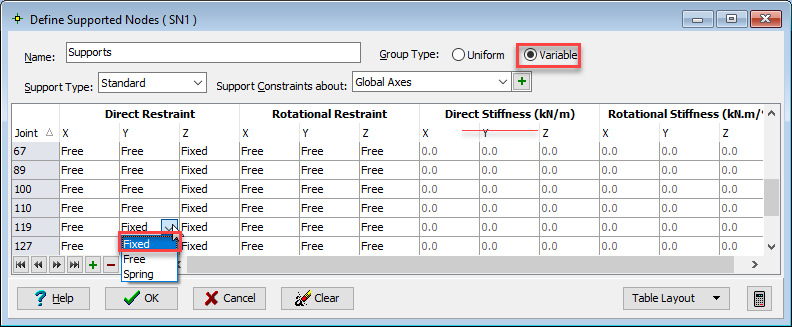

In the Define Supported Nodes form you will see that the Group Type: is set to Uniform, which means all the support conditions are the same.

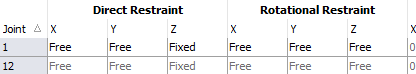

Set the restraints in the first row such that all degrees of freedom are Free except Direct Restraint Z, which is Fixed.

Now change the Group type: to Variable, which allows each support to have different constraints applied.

We also change the Select mode (in the graphics window) to Create.

To fix the X and Y translational constraints on the centre support along the left span end line we first click on this one support node in the graphics screen (which highlights it in the table). In this row of the table we change the X and Y Direct Restraints to Fixed.

Item 37 is repeated for the centre support under the right span end line, except that we only change the Y Direct Constraint to Fixed.

Close the Define Supported Nodes form using the ✓ OK button.

Properties

There are only two properties to define.

The 500mm thick slab property which can be assigned to all members except the leftmost diaphragm members.

A parametric rectangular shape member 10mm by 10mm as a nominally low stiffness member assigned to the leftmost diaphragm members.

The slab can be defined directly in the structure properties but the parametric rectangular shape first needs to be created as a design section.

In the Design Sections navigation window toolbar click on the

button and select New Section | Parametric Shape.

button and select New Section | Parametric Shape.In the Define Section Element form change both width and depth to be “10”mm, the Hook Point Reference to “0” with Y & Z Coordinates “0” and the Property to that of grade 40/50 concrete.

The Name can also be changed to “10x10 Rectangle” before closing the form with the ✓ OK button.

Left click on SS1: Section in the navigation window and then left click to rename the section as “Nominal Section.”

Change the navigation window to Structure Properties and click on the button to select Design Section. As there is only one Design Section, this is automatically loaded.

Now assign this property to the leftmost line of diaphragm members by selecting them in the graphics window (this can be done by boxing round them).

Close the Structure Properties: Section form with the ✓ OK button.

Click on the

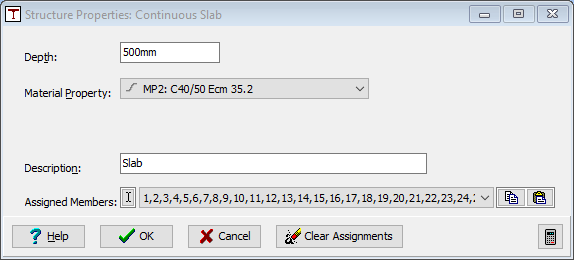

button again at the top of the navigation window and select Continuous Slab.

button again at the top of the navigation window and select Continuous Slab.In the_ Structure Properties: Continuous Slab_ form, change the Depth: to “500”, and ensure that the Material Property is set to the grade 40/50 concrete.

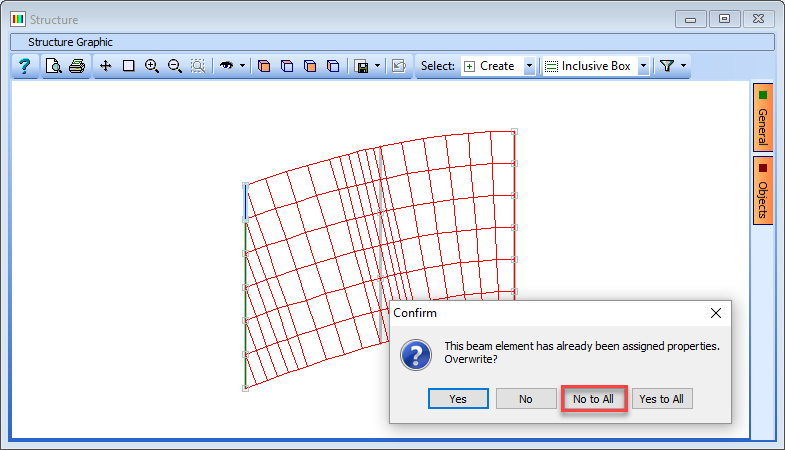

Window round the whole structure to assign this property to all members. As some members have already been assigned properties a Confirm form is displayed. Selecting the No To All button will prevent any overwriting.

Close the Continuous Slab Properties form with the ✓ OK button.

Save the data file using the main menu File | Save as with a name of “My EU Example 6_4.sst”.

Data Reports

One of the first things we will do is create a graphical plot showing all the node and element numbers in one of the spans.

In the Structure Definition navigation window, click on the “Structure” item.

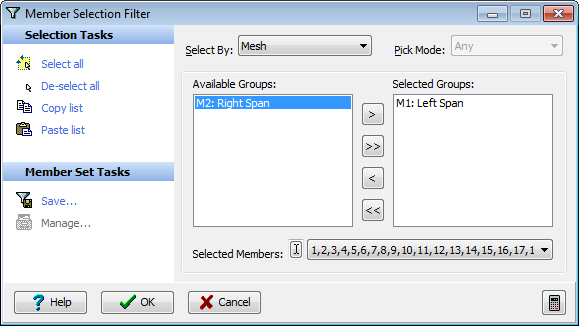

In the graphics window toolbar click on the filter button to open the Member Selection Filter form.

Click on the Selection Task De-Select all.

Change Select By: to Mesh and then move the M1:Left Span item from the Available Group: into the Selected Groups: by double clicking on it.

Close the form with the ✓ OK button.

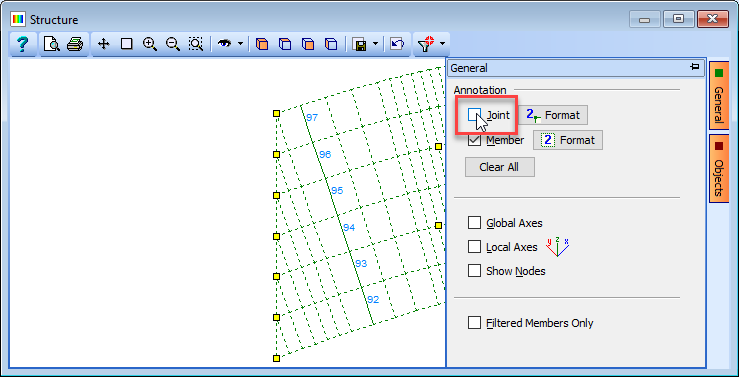

In the graphics window, click on the orange General button at the right hand side and tick the Filtered Members Only option and tick the Joint and Member Annotation objects (this window disappears automatically when the cursor is moved away from the form).

Now click on the orange Objects button and de-select everything except Beam Elements and Supported Nodes.

To make the annotation readable maximize the graphics screen and fit the structure to the window with the Fit View graphics toolbar icon

.

.Click on the orange “General” button again and click on the “Format” button adjacent to the Members annotation option.

In the Text Setup form set the vertical offset to “6” and the colour to Blue.

Close the form with the ✓ OK button.

The text should now be readable.

To get a hardcopy plot of this click on the Print Preview graphics toolbar icon

to display the Print preview window.

to display the Print preview window.Use the menu item Format | Title to open the Titles form.

Tick the option for Show User Title Block and enter “Joint and Member Numbering for Span 1” in the visible text field. This preview can then be printed on your system printer by using the File |Print menu item. Also, a PDF of the graphic window can be generated by clicking on the icon at the top of the print preview window before.

Close the preview window.

Restore the graphics window to its normal size.

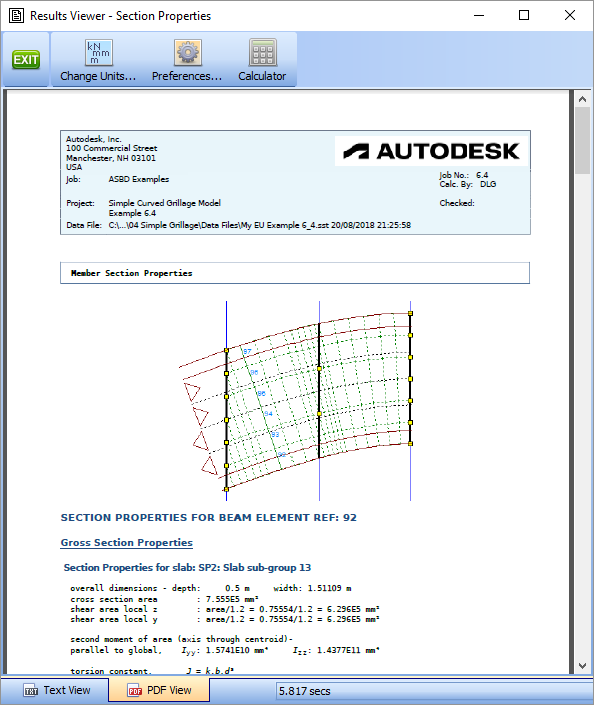

We are now going to create a report showing the calculation of the section properties of a row of transverse members.

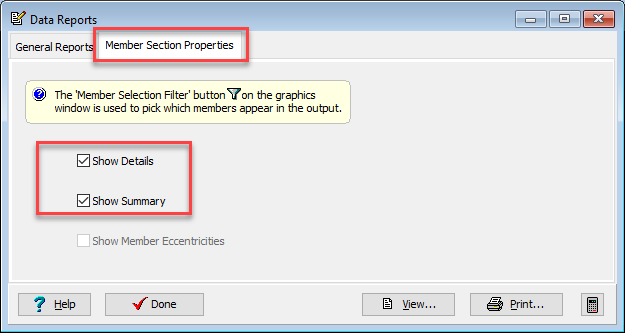

In the main menu select File | Data Reports

In the Data Reports form, select the Member Section Properties tab and ensure that Show Details and Show Summary are ticked.

In the graphics window toolbar, click on the Filter icon to open the Member Selection Filter form.

Set the Pick Mode: to Transverse beam and then click on one of the transverse beams in the graphics window as shown before closing the Selection Filter form.

Switch off joint annotation in the General tab.

Click on the View... button on the Data Reports form to show the basic Results Viewer. Although this doesn't show the graphics directly, if this form is printed (or print preview) it will have the current graphics included at the top of the report.

Alternatively, if it was required to save a high quality PDF file of this report then click on the “PDF View” tab at the bottom of the Data Reports form. This view can be saved to a local PDF file.

Close the Results Viewer using the green Exit button and then close the Data Reports form using the ✓ Done button. The program can now be closed.

Summary

This simple grillage of a curved flat slab highlights all the basic methods for creating any grillage structure and introduces most of the tools required to create a grillage and get data reports. The model that has been saved will be used in the loading and analysis of this structure in Section 7 of this tutorial.