Activity 10: Pencil cut2

In this activity, we will use use the 3D Pencil strategy again, to reduce the amount of stock in the corners of the cavity, with a smaller tool.

Previously we used a 3 mm ball mill. Now we will use a 2 mm ball mill.

Prerequisites

- Activity 9 is complete.

Steps

Start a new 3D Pencil operation and, from the Tutorial Tools (Metric) library, select the #23 - Ø2 mm R1 mm ball tool.

- On the Manufacture toolbar, Milling tab, select 3D > Pencil

.

. - On the Tool tab

, click Select. This opens the tool library.

, click Select. This opens the tool library. - In the Tool Library dialog, select Fusion Library > Tutorial Tools (Metric).

- From the list, select #23 - Ø2 mm R1 mm (Ball end mill).

- Click Select.

- On the Manufacture toolbar, Milling tab, select 3D > Pencil

Stepover cut value, cut angle.

- Click the Passes tab

.

. - Set Stepover to .08 mm.

- Set Number of Stepovers to 11.

- Click OK to begin calculating the toolpath.

- Click the Passes tab

Activity 10 summary

In this activity you selected a 3D Pencil finishing operation and used a smaller tool to clean out the fine corners.

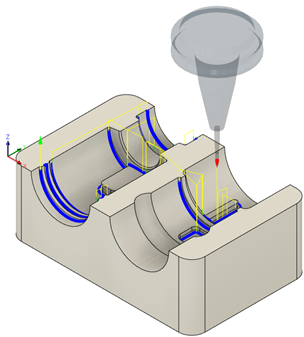

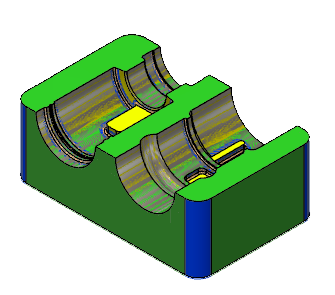

| The calculated toolpath is shown below. | The Simulated toolpath is shown below. |

|

|

The toolpath is shown with a red arrow start, yellow rapid move, green lead in/out move, blue cutting moves and a green arrow at the end.