Activity 5: Rest machining

In this activity, we will use the Adaptive Clearing strategy to remove additional REmaining STock (REST) from the cavity.

Prerequisites

- Activity 4 is complete.

Steps

Duplicate the existing 3D Adaptive Clearing operation, rename the copy.

In the Browser select the existing 3D Adaptive operation.

Right-click and select Duplicate.

Left click the new Copy and change the name to "Adaptive - Rest".

Right-click the new operation and select Edit.

The dialogfor the new operation opens. Notice that all parameter values are the same as the previously created Adaptive Clearing operation.

Tip: In many cases, creating a copy (using Duplicate or Copy and Paste) is faster than creating a new operation since many operations will use the same basic parameters.

Select a tool from the Tutorial Tools (Metric) library, select the #14 - Ø5 mm R0.5mm bullnose.

- On the Tool tab

, click Select. This opens the tool library.

, click Select. This opens the tool library. - In the Library, select Fusion Library > Tutorial Tools (Metric)

- From the list, select #14 - Ø5 mm R0.5 (Bull nose end mill).

- Click Select.

- On the Tool tab

Depth cut settings, Optimal load and Stock to leave.

- Click the Passes tab

.

. - Set Optimal Load to 1 mm.

- Set Maxiumum Roughing Stepdown to 5 mm.

- Set Fine Stepdown to 1 mm.

- Set Stock to leave Radial and Axial, to .3 mm.

- Click OK to start the calculation.

- Click the Passes tab

Activity 5 summary

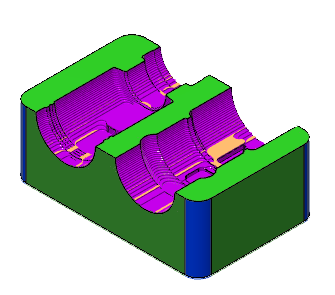

In this activity you duplicated the 3D Adaptive Clearing roughing operation, selected a library tool, reduced the Rest Machining parameters, set the cut stepover, step depth and stock to leave. This removed additional remaining stock.

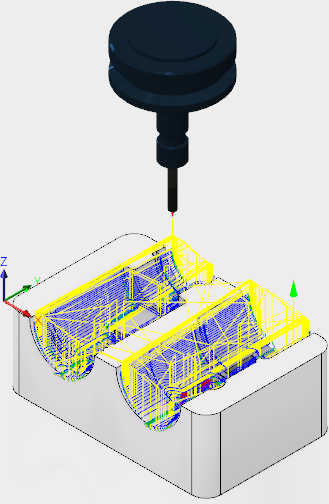

| The calculated toolpath is shown below. | The simulated toolpath is shown below. |

|

|

The toolpath is shown with a red arrow start, yellow rapid move, green lead in/out move, blue cutting moves and a green arrow at the end.