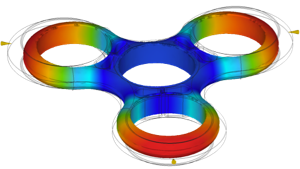

Deflection (all effects) result

The Deflection (all effects) result combines differential cooling, differential shrinkage and orientation effects to show the final part warpage.

Warpage

Warpage is defined as a change in shape compared with the model design. All plastic molded parts warp, so the goal is to reduce warpage to meet the design's warpage tolerance. When several warpage analyses are run, the shape of the warpage may change when inputs change such as geometry, material, injection location, and processing conditions.

Things to look for

When viewing the Deflection (all effects) result, watch for the following:

- The extent to which the part deflects, as indicated by the red color

- The location of the deflection. Deflection in some areas may be of less concern than in others.

Using this result

The Deflection (all effects) result shows you the total predicted deformation of the part, measured against a Best Fit plane. To properly interpret the deflection results, you must consider:

- How the part is going to be used.

- How the part is assembled with other components.

Some parts may have an assembly surface, or sealing surface that must be flat within some tolerance. Other parts have many assembly features like snap fits or screw bosses that must fit to other parts. Many parts have multiple dimensions or geometric tolerances that must be met.

If the deflection values are small, magnify the display of the deflections using the Magnification tool in the Result Settings next to the legend.

Next steps

The following options can be used to reduce the deflection:

- Move injection locations to create a balanced fill pattern

- Edit the simulation model to make wall thicknesses more uniform

- Select a material from the database with a lower average nominal shrinkage. Materials that are gold rated for warpage have more complete material properties data.

- Change the melt temperature

- Change the injection time

- Edit the simulation model to increase the wall thickness.